Troubleshooting – VACUUBRAND MZ 2C NT VARIO without controller (o.C.) User Manual

Page 48

page 48 of 76

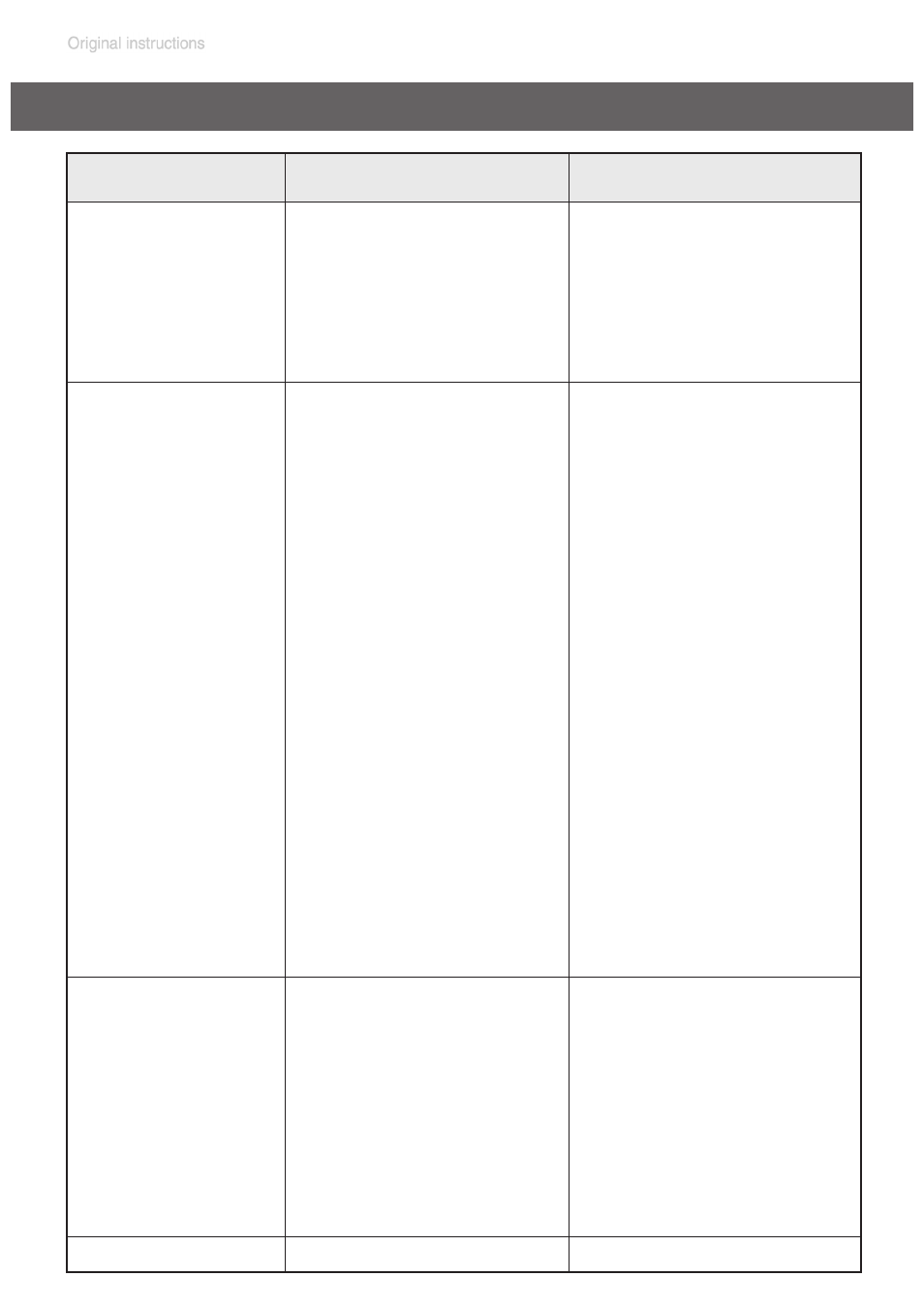

Troubleshooting

Fault

Possible cause

Remedy

❑ Pump does not

start or stops im-

mediately.

➨ Pump has been ex-

posed to condensate?

✔ Allow pump to run for

some minutes at maxi-

mum speed with atmo-

spheric pressure at the

inlet.

➨ Overpressure in outlet

line?

✔ Remove blockage in line,

open valve.

❑ Pump does not

achieve its ulti-

mate vacuum or

usual pumping

speed.

➨ Centring ring at small

flange connection not

correctly positioned, or

leak in the pipeline or

vacuum system?

✔ Check pump directly -

connect vacuum gauge

directly at pump inlet -

then check connection,

pipeline and vacuum

system if necessary.

➨ Long, narrow vacuum

line?

✔ Use lines with larger di-

ameter, length as short as

possible.

➨ Pump has been exposed

to condensate?

✔ Allow pump to run for

some minutes with atmo-

spheric pressure at the

inlet to purge.

➨ Deposits have been

formed inside the pump?

✔ Clean and inspect the

pump heads.

➨ Diaphragms or valves

damaged?

✔ Replace diaphragms and/

or valves.

➨ Outgassing substances

or vapor generated in

the process?

✔ Check process parame-

ters.

➨ Pump too hot?

✔ Allow pump to cool down.

Determine and eliminate

the cause of overheating.

❑ Pump too noisy.

➨ Atmospheric or high

pressure at the pump

inlet?

✔ Connect hose or silencer

to pump outlet. Be careful

not to cause outlet over-

pressure, especially with

condensable vapors.

➨ Diaphragm crack or

diaphragm clamping disc

loose?

✔ Perform maintenance.

➨ Other than above men-

tioned causes?

✔ Contact local distributor.

❑ Pump seized.

✔ Contact local distributor.

- MV 10C VARIO-B without controller (o.C.) ME 4C NT VARIO without controller (o.C.) MD 4C NT VARIO without controller (o.C.) MD 12C VARIO-B without controller (o.C.) PC 3012 VARIO without controller (o.C.) PC 3010 VARIO without controller (o.C.) PC 3004 VARIO without controller (o.C.) PC 3003 VARIO without controller (o.C.) PC 3002 VARIO without controller (o.C.)