Step 2 — rig and mount the unit, Step 3 — complete refrigerant piping connec- tions – Carrier AIR COOLED SPLIT SYSTEM 38AQS008 User Manual

Page 2

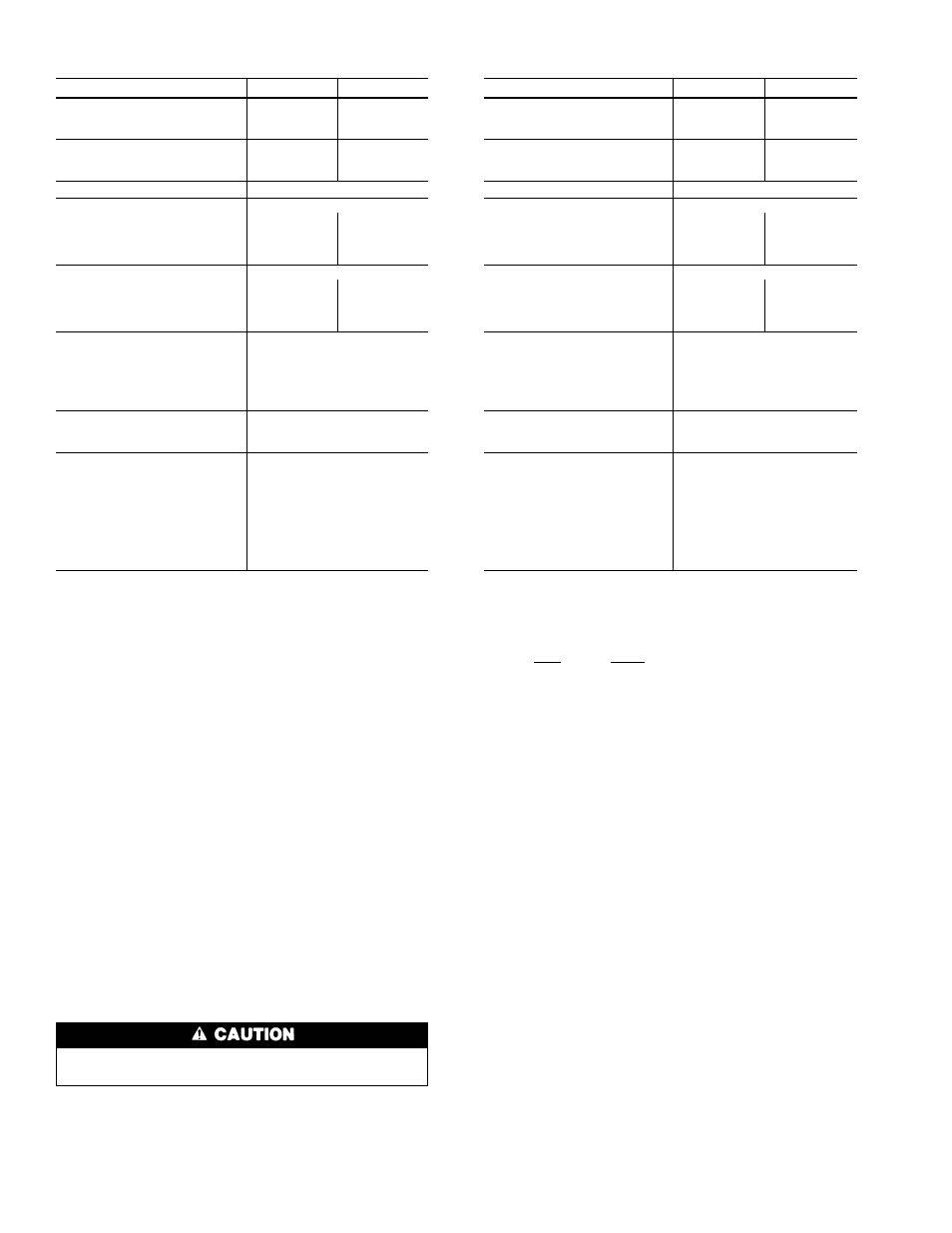

Table 1A — Physical Data (English)

UNIT 38AQS008

60 Hz

50 Hz

OPERATING WEIGHT (lb)

Aluminum Coils (Standard)

540

594

Copper Coils (Optional)

608

662

RIGGING WEIGHT (lb)

Aluminum Coils (Standard)

590

644

Copper Coils (Optional)

658

712

REFRIGERANT*

R-22

COMPRESSOR

Reciprocating, Semi-Hermetic

Quantity...Type

1...06DA818

1...06DA824

Quantity Cylinders

4

6

Speed (rpm)

1750

1460

Oil Charge (oz) (ea)

88

128

OUTDOOR FAN

Propeller; Direct Drive

Quantity...rpm

1...1100

1...960

Diameter (in.)

26

26

Motor Hp (NEMA)

3

⁄

4

1

⁄

3

Nominal Airflow (cfm)

6500

6100

OUTDOOR COIL

Enhanced Copper Tubes,

Aluminum Lanced Fins

Face Area (sq ft)

18.0

Storage Capacity (lb)†

16.56

Fins/in.

17.0

Rows (No.)

2

CONNECTIONS (Sweat)

Suction (in.)

1

1

⁄

8

Liquid (in.)

1

⁄

2

CONTROLS

Pressurestat Settings (psig)

High Cutout

426

Ϯ 7

Cut-in

320

Ϯ 20

Low Cutout

7

Ϯ 3

Cut-in

22

Ϯ 5

Defrost Thermostat

Initiate Defrost (F)

28

Terminates Defrost (F)

65

LEGEND

NEMA — National Electrical Manufacturing Association (U.S.A.)

*Unit is factory supplied with holding charge only.

†Storage capacity of coil with coil 80% full of liquid R-22 at 120 F.

Table 1B — Physical Data (SI)

UNIT 38AQS008

60 Hz

50 Hz

OPERATING WEIGHT (kg)

Aluminum Coils (Standard)

245

270

Copper Coils (Optional)

276

299

RIGGING WEIGHT (kg)

Aluminum Coils (Standard)

268

292

Copper Coils (Optional)

298

323

REFRIGERANT*

R-22

COMPRESSOR

Reciprocating. Semi-Hermetic

Quantity...Type

1...06DA818

1...06DA824

Quantity Cylinders

4

6

Speed (r/s)

29.2

24.2

Oil Charge (L) (ea)

2.60

3.78

OUTDOOR FAN

Propeller; Direct Drive

Quantity...r/s

1...18.3

1...16.0

Diameter (mm)

660

660

Motor Hp (NEMA)

3

⁄

4

1

⁄

3

Nominal Airflow (L/s)

3070

2900

OUTDOOR COIL

Enhanced Copper Tubes,

Aluminum Lanced Fins

Face Area (m

2

)

1.67

Storage Capacity (kg)†

7.5

Fins/m

669

Rows (No.)

2

CONNECTIONS (Sweat)**

Suction (in.)

1

1

⁄

8

Liquid (in.)

1

⁄

2

CONTROLS

Pressurestat Settings (kPa)

High Cutout

2937

Ϯ 48

Cut-in

2206

Ϯ 138

Low Cutout

48

Ϯ 20

Cut-in

151

Ϯ 34

Defrost Thermostat

Initiate Defrost (C)

−2.2

Terminates Defrost (C)

18.3

LEGEND

NEMA — National Electrical Manufacturing Association (U.S.A.)

*Unit is factory supplied with holding charge only.

†Storage capacity of coil with coil 80% full of liquid R-22 at 49 C.

**All pipe sizes are OD inches; equivalent sizes in millimeters follow:

in.

mm

1

⁄

2

12.7

1

1

⁄

8

28.6

CONSIDER SYSTEM REQUIREMENTS

• Consult local building codes and NEC (U.S.A.) for spe-

cial installation requirements.

• Allow sufficient space for airflow clearance, wiring, re-

frigerant piping, and servicing unit. See Fig. 2.

• Locate unit so that outdoor unit airflow is unrestricted on

all sides and above. Refer to Fig. 2.

• Unit may be mounted on a level pad directly on base rails

or mounted on raised pads at support points. See Fig. 2 for

weight distribution based on recommended support points.

• Provide for condensate drainage and defrost water dis-

posal beneath unit.

• Areas with high snowfall may need elevated mounting for

adequate airflow.

NOTE: If vibration isolators are required for a particular in-

stallation, use corner weight information in Fig. 2 to make

proper selection.

Step 2 — Rig and Mount the Unit

Be sure unit panels are securely in place prior to

rigging.

RIGGING — These units are designed for overhead rig-

ging. Refer to rigging label for preferred rigging method.

Spreader bars are not required if top crating is left on unit.

All panels must be in place when rigging. (See Fig. 3.) As

further protection for coil faces, plywood sheets may be placed

against sides of unit, behind cables. Run cables to a central

suspension point so that angle from the horizontal plane is

not less than 45 degrees. Raise and set unit down carefully.

If it is necessary to roll unit into position, mount unit on

rails, using a minimum of 3 rollers. Apply force to rails, not

unit. If unit is to be skidded into position, place it on a large

pad and drag it by the pad. Do not apply any force to unit.

Raise from above to lift unit from rails or pad when unit

is in final position.

After unit is in position, remove all shipping wrapping and

top crating.

MOUNTING — The unit must be elevated to ensure drain-

age from basepan during sub-freezing conditions and to pre-

vent or limit blockage of outdoor coil during snowfall. Con-

sideration should be given to specific geographical areas when

determining height of unit elevation.

COMPRESSOR MOUNTING — As shipped, compressors

are held down by 4 bolts. After unit is installed, loosen each

bolt until the snubber washer can be moved with finger pres-

sure. See Fig. 4.

Step 3 — Complete Refrigerant Piping Connec-

tions —

Suction connection is sweat with plastic cap; liq-

uid connection is sweat with plastic cap. Refer to Table 2 for

the proper line sizes. Follow standard piping practices.

2