Fan maintenance, Motor maintenance, Bearing maintenance – Twin City Inline Fume Exhaust Fans - IM-1080 User Manual

Page 5: Operation checklist

Twin City Fan IM-1080

5

FAN MAINTENANCE

Periodically inspect the shaft and wheel for dirt buildup,

corrosion, and signs of excess stress or fatigue. Clean

the components. If the wheel is removed for any reason,

make sure that it is securely attached to the shaft before

restarting the fan.

All structural components or devices used to support

or attach the fan to a structure should be checked at

regular intervals. Vibration isolators, bolts, foundations,

etc., are all subject to failure from corrosion, erosion,

and other causes. Improper mounting can lead to poor

operation characteristics or fan fatigue and failure. Check

metallic components for corrosion, cracks, or other signs

of stress. Concrete should be checked to insure the

structural integrity of the foundation. See curb installation

section for detail on proper mounting procedures.

MOTOR MAINTENANCE

The three basic rules of motor maintenance are:

1. Keep the motor clean.

2. Keep the motor dry.

3. Keep the motor properly lubricated.

Blow dust off periodically (with low pressure air) to pre-

vent motor from overheating. Some smaller motors are

lubricated for life. Lubrication requirements are normally

attached to the motor. Use the motor manufacturer’s

recommendations for relubrication. If this information is

not available, the following schedule may be used. Mo-

tors less than 10 HP running about eight hours a day in

a clean environment should be lubricated once every five

years; motors 15 to 40 HP, every three years. For motors

in dusty or dirty environments or running 24 hours a day:

divide the service interval by 4. Do not over lubricate.

BEARING MAINTENANCE

Proper lubrication of the fan drive bearings helps assure

maximum bearing life. All fans are equipped with decals

indicating relubrication intervals for normal operating con-

ditions. However, every installation is different and the

frequency of relubrication should be adjusted accord-

ingly. On high moisture applications, the lubrication fre-

quency may need to be doubled or tripled to adequately

protect the bearings. Double the relubrication frequency

on fans with vertical shafts. Observation of the conditions

of the grease expelled from the bearings at the time of

relubrication is the best guide as to whether regreasing

intervals and amount of grease added should be altered.

Greases are made with different bases. There are syn-

thetic base greases, lithium base, sodium base, etc.

Avoid mixing greases with different bases. They could be

incompatible and result in rapid deterioration or break-

down of the grease. The lubrication sticker identifies a

list of acceptable lubricants. All bearings are filled with

a lithium-based grease before leaving the factory. When

the fans are started, the bearings may discharge excess

grease through the seals for a short period of time. Do

not replace the initial discharge because leakage will

cease when the excess grease has worked out. Some-

times the bearings have a tendency to run hotter during

this period. There is no reason for alarm unless it lasts

over 48 hours or gets very hot (over 200°F). When re-

lubricating, use a sufficient amount of grease to purge

the seals. Rotate bearings by hand during relubrication.

OPERATION CHECKLIST

Verify that proper safety precautions have been followed:

□

Electrical power must be locked off

Check fan mechanism components:

□

System connections are properly made and tightened.

□

Bearings are properly lubricated.

□

Wheel, drives and fan surfaces are clean and free of

debris.

□

Rotate the impeller by hand to verify it has not

shifted in transit.

□

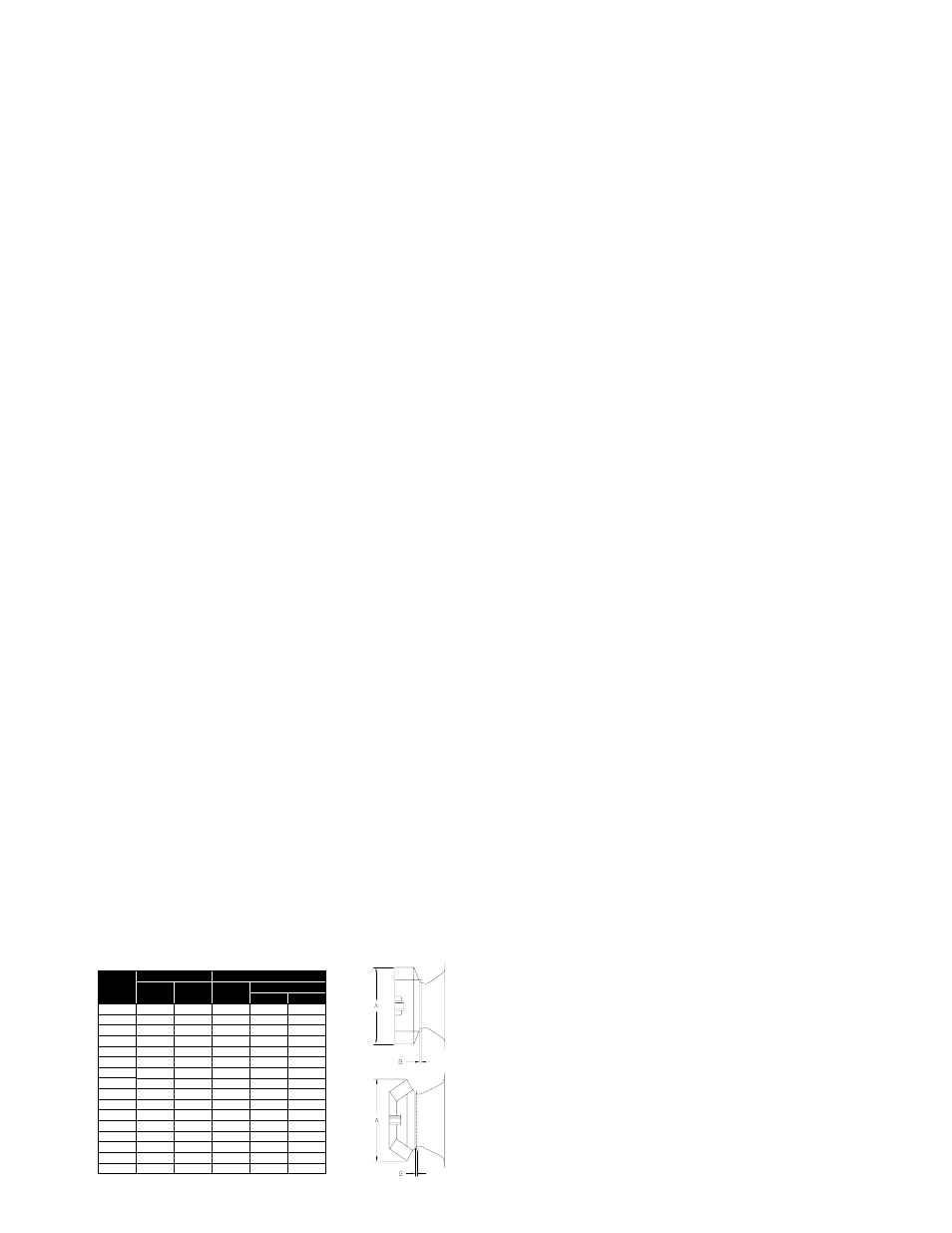

Check fan/wheel overlap. (See Figure 7.)

□

Drives on correct shafts (not reversed).

□

Check position of guards to prevent rubbing.

Check fan electrical components:

□

Motor is wired for proper supply voltage.

□

Motor was properly sized for power and rotational

inertia of rotating assembly.

□

Motor is properly grounded.

□

All leads are properly insulated.

Trial “bump”:

□

Turn on power just long enough to start assembly

rotating.

□

Check rotation for agreement with rotation arrow.

□

Does the assembly make any unusual noise?

□

Check drive alignment and tension. Does this meet

with drive manufacturer’s recommendations?

□

Correct any problems which may have been found.

(Follow safety guidelines - shut power off.) Perform

checklist again until unit is operating properly.

□

Run unit up to speed.

Verify fastener tightness. These may have loosened

during shipment or installation.

□

Setscrews attaching wheel hub to shaft.

□

Setscrews in drive sheaves or coupling.

□

Nuts on inlet funnel.

□

Nuts and bolts holding motor.

□

Nuts holding housing frame to base and base to

ground.

□

Nuts on accessories including shaft seal, access

doors and pie-splits.

□

Bolts in taper-lock bushings.

□

Grease line connections.

After one week of operation, check all nuts, bolts and

setscrews and tighten if necessary.

Figure 7.

FAN

SIZE

TFE

QFE, QIFE, TVIFE

A

B

A

B

MIN.

MAX.

90

–

–

12.25

0.25

0.38

122

12.25

0.31

15.00

0.31

0.44

135

–

–

16.50

0.38

0.50

150

15.00

0.38

18.25

0.44

0.56

182

18.25

0.56

20.00

0.50

0.63

200

20.00

0.63

22.25

0.56

0.69

222

22.25

0.69

24.50

0.63

0.75

245

24.50

0.75

27.00

0.69

0.88

270

27.00

0.88

30.00

0.75

0.97

300

30.00

0.97

33.00

0.88

1.06

330

33.00

1.06

36.50

0.75

0.94

365

36.50

0.94

40.25

0.81

1.03

402

40.25

1.03

44.50

0.88

1.13

445

44.50

1.13

49.00

1.00

1.25

490

49.00

1.25

54.25

1.13

1.38

542

54.25

1.38

60.00

1.25

1.56