Bearing maintenance, Wheel and shaft maintenance, Structural maintenance – Twin City Heavy Duty Centrifugal Fans - ES-995 User Manual

Page 5: Duct connections, Optional accessories

5

Twin City Engineering Supplement ES-995

reinstall belts. Tighten sheave bolts (or setscrews if appropriate).

When replacing belts, replace the entire set. Never use belt

dressing on any belts.

Bearing Maintenance

Proper lubrication of the fan drive bearings helps assure maxi-

mum bearing life. All fans are equipped with decals indicating

relubrication intervals for normal operating conditions. Figures

5, 6, and 7 illustrate the lubrication schedules for ball bear-

ings, solid pillow block spherical roller bearings, and split pil-

low block spherical roller bearings, respectively. Note that all

speeds shown do not apply to all shaft sizes in that group.

Consult the factory if in doubt of maximum speed for a par-

ticular bearing. Note that every installation is different and the

frequency of relubrication should be adjusted accordingly.

On high moisture applications the lubrication frequency may

need to be doubled or tripled to adequately protect the bear-

ings. Double the relubrication frequency on fans with vertical

shafts.

Observation of the conditions of the grease expelled from

unit ball or roller bearings at the time of relubrication is the

best guide as to whether regreasing intervals and amount of

grease added should be altered. Spherical roller bearings with

split pillow block housings should be lubricated until grease

purges or overheating may result. Follow the lubrication interval

and amount noted in Figure 7. Spherical roller bearings with

split pillow block housings should be serviced once per year.

Remove cap, clean out old grease and replace by filling the

bottom half of the housing 1/3 full.

Greases are made with different bases. There are synthetic

base greases, lithium base, sodium base, etc. Avoid mixing

greases with different bases. They could be incompatible and

result in rapid deterioration or breakdown of the grease. The

lubrication sticker identifies a list of acceptable lubricants. All

bearings are filled with a lithium-based grease before leaving

the factory. When the fans are started, the bearings may dis-

charge excess grease through the seals for a short period of

time. Do not replace the initial discharge because leakage will

cease when the excess grease has worked out. Sometimes

the bearings have a tendency to run hotter during this period.

This is no reason for alarm unless it lasts over 48 hours or

gets very hot (over 200°F). When relubricating, use a sufficient

amount of grease to purge the seals. Rotate bearings by hand

during relubrication.

Wheel and Shaft Maintenance

Periodically inspect the shaft and wheel for dirt buildup, corro-

sion, and signs of excess stress or fatigue. Clean the compo-

nents. If the wheel is removed for any reason, make sure that

it is securely attached to the shaft before restarting the fan.

Structural Maintenance

All structural components or devices used to support or attach

the fan to a structure should be checked at regular intervals.

Vibration isolators, bolts, foundations, etc., are all subject to

failure from corrosion, erosion, and other causes. Improper

mounting can lead to poor operation characteristics or fan

fatigue and failure. Check metallic components for corrosion,

cracks, or other signs of stress. Concrete should be checked

to insure the structural integrity of the foundation.

Duct Connections

The fan support structure is normally not designed to carry

loads imposed by the weight of ducts, silencers, stacks, etc.

Supporting these loads on the fan can cause housing distor-

tion and may cause performance problems due to the rela-

tion of fan housing to wheel. Use of flexible connections is

recommended when using vibration isolation or handling high

temperature gases.

Optional Accessories

1.

Turning Gear — A turning gear is sometimes used in

high temperature applications where the fan is exposed

to high temperature gases while not operating. The wheel

and shaft can expand unevenly due to the temperature

when sitting idle, which can cause vibration at startup

and/or a permanent set to the rotor. The turning gear

slowly turns the fan from the outboard side while it is not

operating, providing for even thermal expansion. It starts

automatically when the fan shuts down and disengages

automatically when the fan starts up again. More specific

information will be provided for each application.

2.

Shaft Seals — The standard shaft seal is a ceramic fiber

element retained with an aluminum retaining plate and

clips. Other configurations of shaft seals are available for

special applications, such as when it is necessary to keep

the shaft seal as gas tight as possible. Shaft seal appli-

cation manuals are provided in Engineering Supplement

ES-595.

3.

Variable Inlet Vanes — Variable inlet vanes are provided

as assemblies internally in the inlet cone or externally in

a flanged cylinder. The vanes are used to control volume

and save power in installations where different volumetric

operating conditions are used. Installation manuals are

provided in other engineering supplements for specific fan

types. Variable inlet vanes may be provided with powered

operators in which case the manufacturer’s installation and

operating manuals will be provided.

4.

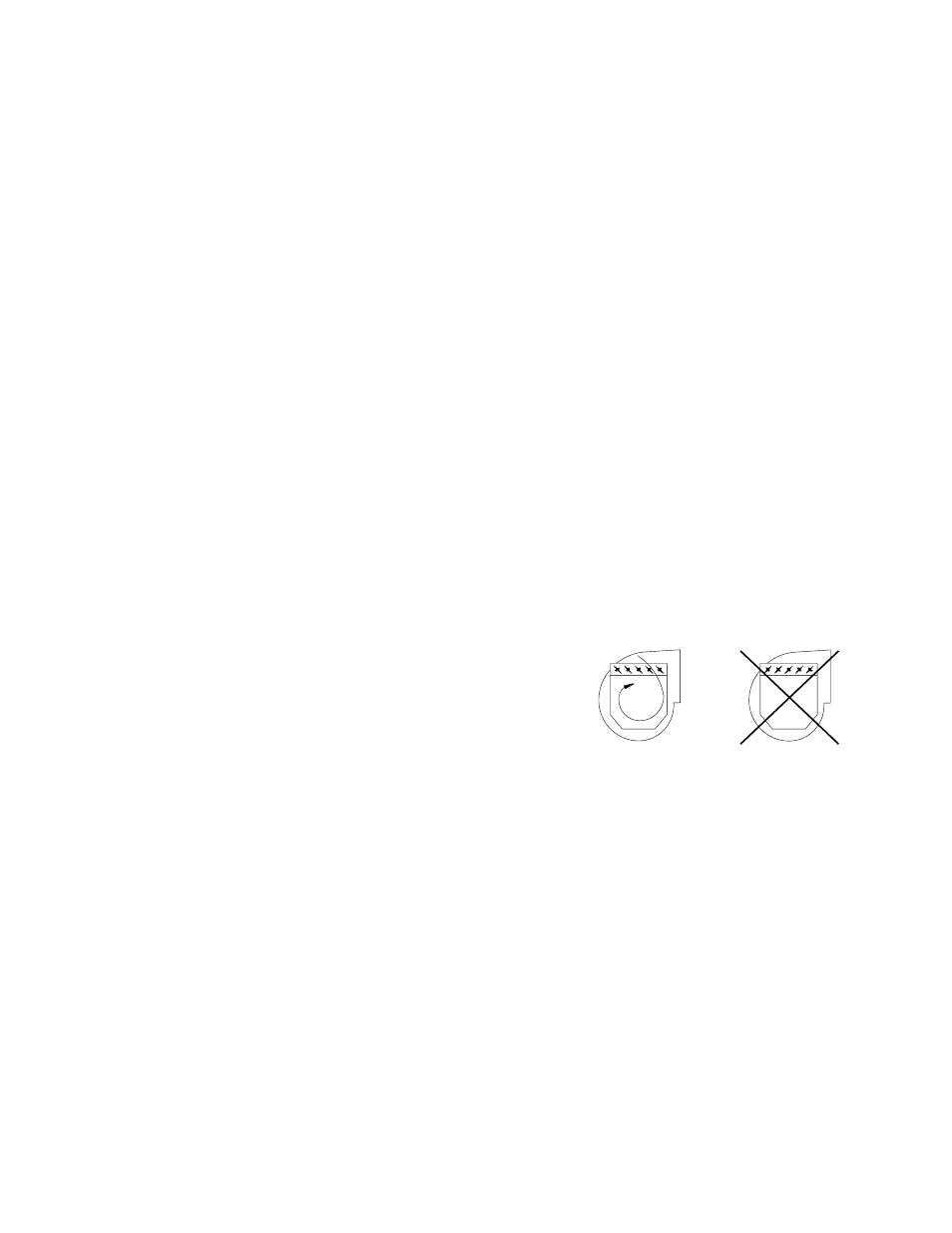

Inlet Box and Inlet Box Dampers — Inlet boxes may be

provided to allow transition from a duct to the fan inlet.

Inlet box dampers may also be provided for volumetric

regulation similar to inlet vanes. Dampers are usually

provided as a complete assembly and are installed with

the damper axles parallel to the fan shaft. They should

be installed to pre-spin the air in the direction of fan

rotation. See Figure 3. Damage may occur if the fan is

operated regularly with damper settings less than 30%

open. Operation below 30% should be limited to start-up

or occasional periods of low duration.

Figure 3. Orientation of Damper Blades As Related

to Fan Rotation

5. Outlet Dampers — Outlet dampers are usually provided

completely assembled like the inlet dampers. The damper

is bolted to the fan discharge for volume control.

6.

Shaft Cooler — Also referred to as “heat slingers” or

“cooling wheels,” these are small, radially bladed aluminum

wheels that are split and bolted for installation between the

inboard bearing and fan housing. The backplate usually is

closest to the fan housing and the blades face the bear-

ing. Specific instructions will be provided by application.

7.

Oil Circulating Systems — Usually the following modifica-

tions will have to be made to the bearing if an oil circulat-

ing system is used.

a. Four drain holes will be drilled in the bearing, two on

each side of the bearing. Because of this, the bearing

may be drained from either side. (Drain from both holes

on one side of the bearing.)

b. It is not necessary to drain the bearing.

c. The bearing will be packed with grease to prevent corro-

sion until installed and started up. The drain holes will be

plugged with plastic covers to make sure they are open.

The customer MUST REMOVE most of the grease using

solvent and remove the plastic covers prior to starting

the oil circulating system.

d. A wet sump will be added in case of circulating oil

pump failure. Seals will be provided to accommodate the

RIGHT

WRONG