Bearing installation, Figure 2. wheel placement (wheel overlap) – Twin City Heavy Duty Centrifugal Fans - ES-995 User Manual

Page 3

3

Twin City Engineering Supplement ES-995

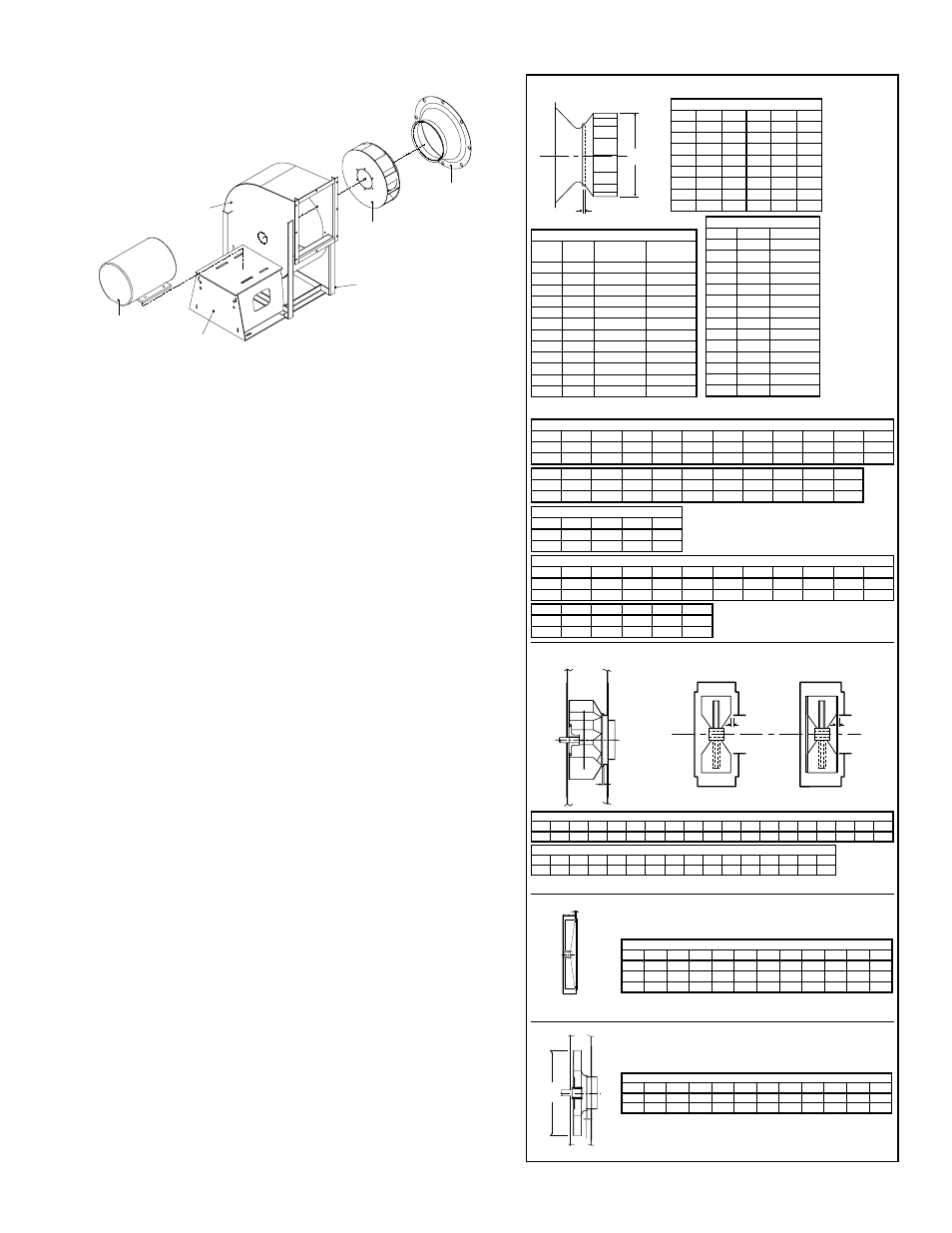

drive bearing and sheaves. Mount bearing bar assembly

to housing. See Figure 2 for wheel-funnel overlap.

a. Assemble parts in above order on shaft.

b. Proceed with connection of the shaft assembly to sup-

ports in step 7 above.

10. Install motor on the base if applicable. Carefully align

shafts for drive installation.

11. Fans that have motors and drives mounted at the factory

are trim balanced prior to shipment. This is not possible

on units that are shipped without motors and drives.

The addition of drive components in the field can create

unbalance forces. Twin City Fan & Blower recommends

final balancing of the unit after the drive components

are installed. Failure to do so voids the Twin City Fan &

Blower warranty.

Bearing Installation

The following section gives some general instructions on bear-

ing installation. If bearings are to be field installed, the specific

installation manual for the bearings will be provided and should

be followed carefully. Always make sure to check the assembly

drawings and bearing manufacturer's instructions for location

of the fixed and expansion bearings. The positions of these

bearings cannot be interchanged.

Sleeve Bearings

1. The bearings should be disassembled and cleaned with

appropriate solvent, taking care not to interchange parts

between bearings. Parts of one bearing are generally not

interchangeable with parts from another bearing.

2. The lower bearing housing should be bolted loosely to

the pedestal. The lower liner should then be placed in the

housing.

3. Oil the lower liner per manufacturer’s instructions and

carefully sling the rotor assembly into place, being very

careful not to damage the bearing liners.

4. Make sure to install the oil slinger rings in their correct

location and peen the ring screws in place.

5. When handling the liners, be careful not to damage the

surfaces, as they are babbitted and are fragile.

6. The housings are generally tapped with a number of ports.

Be sure the oil level gauge, circulating oil supply and

discharge, thermocouples, etc., are correctly connected.

7. Make sure that proper oil type and quantity is used.

8. Make sure that the thrust collar screws, liner screws, cap

bolts, and plunger are torqued to manufacturer’s specifica-

tions.

Spherical Roller Bearings with Split Pillow Block Housings

1. The bearings should be disassembled, taking care not to

interchange parts between bearings. Parts of one bearing

Motor

Pedestal

Housing

Support Stand

(Housing Frame)

Wheel/

Impeller

Inlet

Funnel

Figure 1. Exploded View of Arrangement 4, SWSI Fan

Components

RBO, RBR Wheel Placement

Size 913 915 917 919 921 923 926 929 933 937 941 945 949 954 960

B

0.53 0.53 0.59 0.69 0.78 0.88 0.97 1.03 1.22 1.38 1.56 1.69 1.81 1.88 2.16

A

DIA

B

RBO

RBR

B

B

Figure 2. Wheel Placement (Wheel Overlap)

HIB, RTF Wheel Placement

Size

A

B

Size

A

B

180 20.50 0.31 400 45.25 0.69

200 22.50 0.34 450 50.00 0.75

220 25.00 0.38 490 55.13 0.81

240 27.50 0.44 540 61.00 0.91

270 30.38 0.47 600 67.50 1.00

300 33.50 0.50 660 74.25 1.13

330 37.00 0.56 730 82.00 1.22

360 41.00 0.63 800 90.75 1.34

HIB, RTF, HRT, HAF, BC, BCS, BAF, BAE

BC-SW, BC-DW, BCS, BAF SWSI & DWDI Wheel Placement

Size

122

135

150

165

182

200

222

245

270

300

330

A

12.25 13.50 15.00 16.50 18.25 20.00 22.25 24.50 27.00 30.00 33.00

B

0.32

0.34

0.38

0.44

0.56

0.63

0.69

0.75

0.88

0.97

1.06

RBA, RBO, RBR, RBP & RBW

Size

365

402

445

490

542

600

660

730

807

890

A

36.50 40.25 44.50 49.00 54.25 60.00 66.00 73.00 80.75 89.00

B

0.94

1.03

1.13

1.25

1.38

1.56

1.69

1.88

2.09

2.28

BAE SWSI & DWDI Wheel Placement

Size

182

200

222

245

270

300

330

365

402

445

490

A

19.00 20.82 23.16 25.51 28.11 31.23 34.36 38.00 41.90 46.33 51.01

B

0.38

0.41

0.46

0.50

0.55

0.62

0.68

0.75

0.83

0.91

1.01

Size

542

600

660

730

807

A

56.48 62.47 68.71 76.00 84.07

B

1.11

1.23

1.36

1.50

1.66

BAE SWSI & DWDI Wheel Placement

Size

122

135

150

165

A

12.25 13.50 15.00 16.50

B

0.31

0.34

0.38

0.44

A

RBA

RBA Wheel Placement

Size 907 909 911 913 915 917 919 921 923 926 929 933 937 941 945 949 954 960

A

0.25 0.38 0.47 0.53 0.59 0.69 0.69 0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

MBW, MBO & MBR

MBW, MBO, MBR Wheel Placement

Size 196

224

252

280

308

336

365

421

477

533

589

MBW 0.50 0.44 0.38 0.25 0.38 0.44 0.56 0.63 0.75 0.75 0.88

MBO 0.50 0.44 0.38 0.25 0.38 0.44 0.56 0.63 0.75 0.75 0.88

MBR 0.25 0.25 0.25 0.25 0.25 0.25 0.38 0.56 0.69 0.81 0.94

GAP

B

A

Dia.

BCN Wheel Placement

Size

270

300

330

365

402

445

490

542

600

660

730

A

27.00 30.00 33.00 36.50 40.25 44.50 49.00 54.25 60.00 66.00 73.00

B

0.09

0.09

0.13

0.13

0.13

0.16

0.16

0.19

0.22

0.22

0.25

BCN

Note: On sizes

RBO and RBR 905-911 wheel is to be centered in housing.

*For HAF overlap dimensions, consult Twin City

Fan & Blower.

Note: On sizes 421-589 wheel is to be centered in housing.

HRT Wheel Placement

Size

A

B

(Design 19)

B

(Design 23)

270

27.00

0.50

0.50

300

30.00

0.69

0.69

330

33.00

0.69

0.69

360

36.50

0.81

0.81

400

40.25

1.03

0.97

450

44.50

1.13

1.06

490

49.00

1.25

1.13

540

54.25

1.38

1.25

600

60.00

1.31

1.31

660

66.00

1.56

1.44

730

73.00

1.75

1.63

800

80.75

1.06

1.31

HAF Wheel Placement

Size

A

B

220

240

270

300

330

360

400

450

490

540

600

660

730

800