Drive mounting, Flexible couplings, Motor maintenance – Twin City Heavy Duty Centrifugal Fans - ES-995 User Manual

Page 4: Drive maintenance and installation

4

Twin City Engineering Supplement ES-995

are generally not interchangeable with parts from another

bearing.

2. The lower bearing housing should be bolted loosely to the

pedestal and seals; bearing and adapter sleeve housing

should be placed loosely on the shaft.

3. The rotor assembly with the seals and bearings should

next be positioned over the housings and carefully placed

into the lower housings.

4. The thrust locking ring should be installed in the bearing

closest to the drive sheave or coupling unless otherwise

noted in the drawing. The bearing race should be cen-

tered in the expansion bearing. The exception may be on

Arrangement 3 or 7 fans with a high operating tempera-

ture. Refer to the fan drawing for location.

5. When installing adapter sleeves, tighten for reduction in

clearance per manufacturer’s instructions.

6. Bend down a tab on the lockwasher after finishing adjust-

ment. If there is no lockwasher, tighten the setscrews

found on the locknut.

7. Grease or oil according to manufacturer’s instructions.

8. Install the bearing housing cap bolts and bearing mount-

ing bolts. Tighten bearing housing cap bolts and bearing

mounting bolts. Torque to bearing manufacturer's instruc-

tions.

Solid Pillow Block

1. Slide shaft in bearing bore to proper location.

NOTE: Shaft

should slide easily if self-aligning feature of the shaft is

within its limits. Sling the rotor assembly into place and

loosely bolt the bearings in place.

2. When bearings are in place, torque the base bolts using

values from Table 2 and tighten the collar setscrews to

manufacturer’s specification.

3. Grease or oil according to manufacturer’s instructions.

Drive Mounting

Mount drives as follows:

1. Slip (do not pound) proper sheave onto corresponding

shaft. To minimize bearing loading, mount sheaves as

close to bearings as possible.

CAUTION: Placing fan

sheave on motor can overspeed wheel and cause structural

failure.

2. Align sheaves with straightedge extended along sheaves,

just making contact in two places on outside perimeters

of both sheaves. This “four-point” alignment may also be

checked with a string tied to the shaft behind one of the

sheaves. The string is then pulled taut over the faces of

the sheaves to check the alignment at the four points at

the outside perimeters. Each sheave should be rotated

about one-half revolution during this check to look for

excessive runout or a bent shaft.

3. Install and tighten the belts. Run the drive for a few min-

utes to seat the belts. When tightening the belts, slide the

motor in to slip the belts on. Do not use a pry bar, as

this may damage the belt cords. Tighten the belts to the

proper tension. Ideal tension is just enough tension so that

the belts do not slip under peak load. Many drives are

provided with tensioning data which identifies the load to

apply at the center of the span and the allowable deflec-

tion from this force. This may be checked visually (look

for a slight bow on slack side), or listen for a squeal on

start up, indicating that the belts are too loose. Recheck

sheave alignment.

4. After initial installation of belts, recheck belt tension again

after a few days to adjust belt tension. (New belts require

a break-in period of operation.)

Flexible Couplings

These instructions are general for the installation of several

types of flexible couplings and should not be used as a sub-

stitute for more specific manufacturer’s instructions. The cou-

pling manufacturer’s installation data is available and will give

specific dimensions for alignment limits, lubricants, etc. Refer

to Item 7 in "Factory Assembled Units" section for coupling

alignment requirements.

Before preparing to mount the coupling, make sure that all

bearings, inlet vanes, shaft seals, or other components have

been installed on the shaft.

When mounting and keying the coupling halves to the

shaft, follow supplied instructions for heating and shrink fitting.

Set the coupling halves for the normal gap specified by the

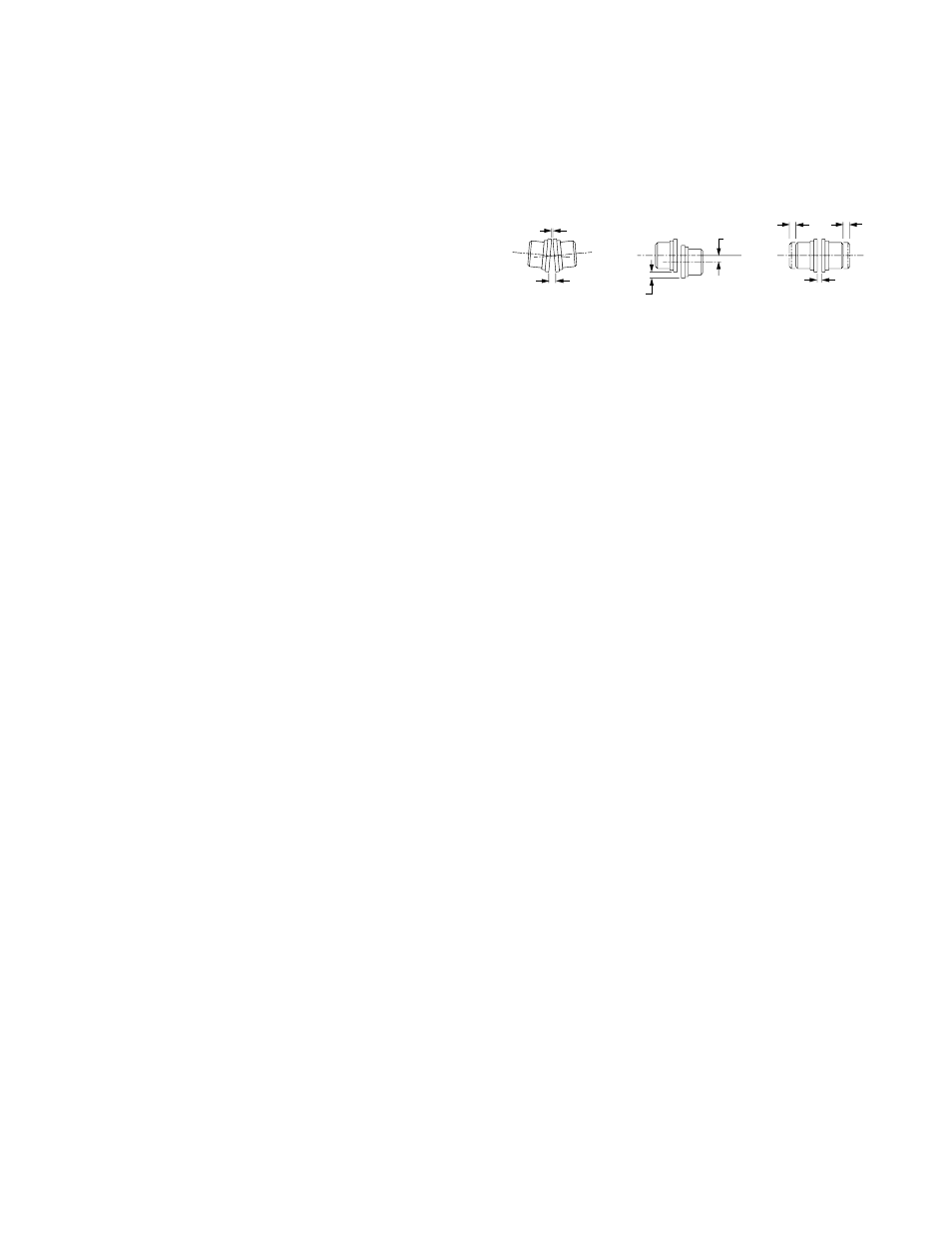

manufacturer. Coupling gap is illustrated below.

The two types of misalignment are illustrated above. Typically

angular alignment is checked with feeler gauges between the hub

faces. When angular alignment has been adjusted to manufac-

turer’s specification by shimming, if necessary, parallel alignment

can be checked with a straightedge and feeler gauges on the

hub halves’ O.D. When shimming has brought parallel alignment

within specification, angular alignment and gap should again be

checked, and adjustments made if necessary. A dial indicator or

laser alignment may be used to more accurately take the mea-

surements described above.

Special adjustments may need to be made for couplings used

with some equipment. As an example, when used with motors

of over 300 HP, couplings may require provisions for limiting

end float. Larger drivers may grow in operation (due to heat

expansion) requiring the driver side to be set slightly low when

not operating. Refer to specific instruction manuals or assembly

drawings.

Thoroughly clean the coupling halves after completion of align-

ment. Reassemble the coupling and tighten bolts, washers and

locknuts. Lubricate per manufacturer’s recommendations.

Motor Maintenance

The three basic rules of motor maintenance are:

1. Keep the motor clean.

2. Keep the motor dry.

3. Keep the motor properly lubricated.

Blow dust off periodically (with low pressure air) to prevent

motor from overheating.

Some smaller motors are lubricated for life. Lubrication

requirements are normally attached to the motor. Use the motor

manufacturer’s recommendations for relubrication. Often motor

lubricants are not the same as the fan bearings. If this information

is not available, the following schedule may be used. Motors less

than 10 HP running about eight hours a day in a clean environ-

ment should be lubricated once every five years; motors 15 to 40

HP, every three years. For motors in dusty or dirty environments

or running 24 hours a day: divide the service interval by 4. Do

not over lubricate.

Drive Maintenance and Installation

V-belt drives need periodic inspection, retensioning, and occa-

sional belt replacement. When inspecting drives, look for dirt

buildup, burrs or obstructions that can cause premature belt or

drive replacement. If burrs are found, use fine emery cloth or a

stone to remove them. Be careful that dust does not enter the

bearings.

Check sheaves for wear. Excessive slippage of belts on

sheaves can cause wear and vibration. Replace worn sheaves

with new ones. Carefully align sheaves to avoid premature sheave

failure. If fraying or other wear is observed to be mostly on one

side of the belts, the drives may be misaligned. Realign and

Y

X

P

P

F

F

GAP

ANGULAR

PARALLEL

GAP AND

MISALIGNMENT

MISALIGNMENT

END FLOAT

X-Y = ANGULAR MISALIGNMENT

P = PARALLEL OFFSET (MISALIGNMENT)

F = END FLOAT