Top Flite S.E.5A User Manual

Page 14

make the rigging wires, which have to be added in any event, perform a real and

important function.

After all the dope on the model is completely dry, screw the lower wing in

place on the fus>elage. Snap the upper wing onto the cabane struts. Snap the four

interplane struts into the wings. The rigging wires are made from the 020" piano

wire supplied, and are called "flying" and "landing" wires — the "flying" wires

are the ones tensioned in flight, that is, the ones running from the fuselage up to

the upper wing the "landing" wires are the ones tensioned in a landing, that is,

the wires running from the top of the cabane struts down to the lower wing

As with the strut fastening method, we have given a good deal of attention

to figuring a simple and fast way to install the rigging wires. We did not want

to use turnbuckles. (the traditional method of getting the correct wire length)

because they are tiresome and must be reset every time the model is disassembled

for transportation

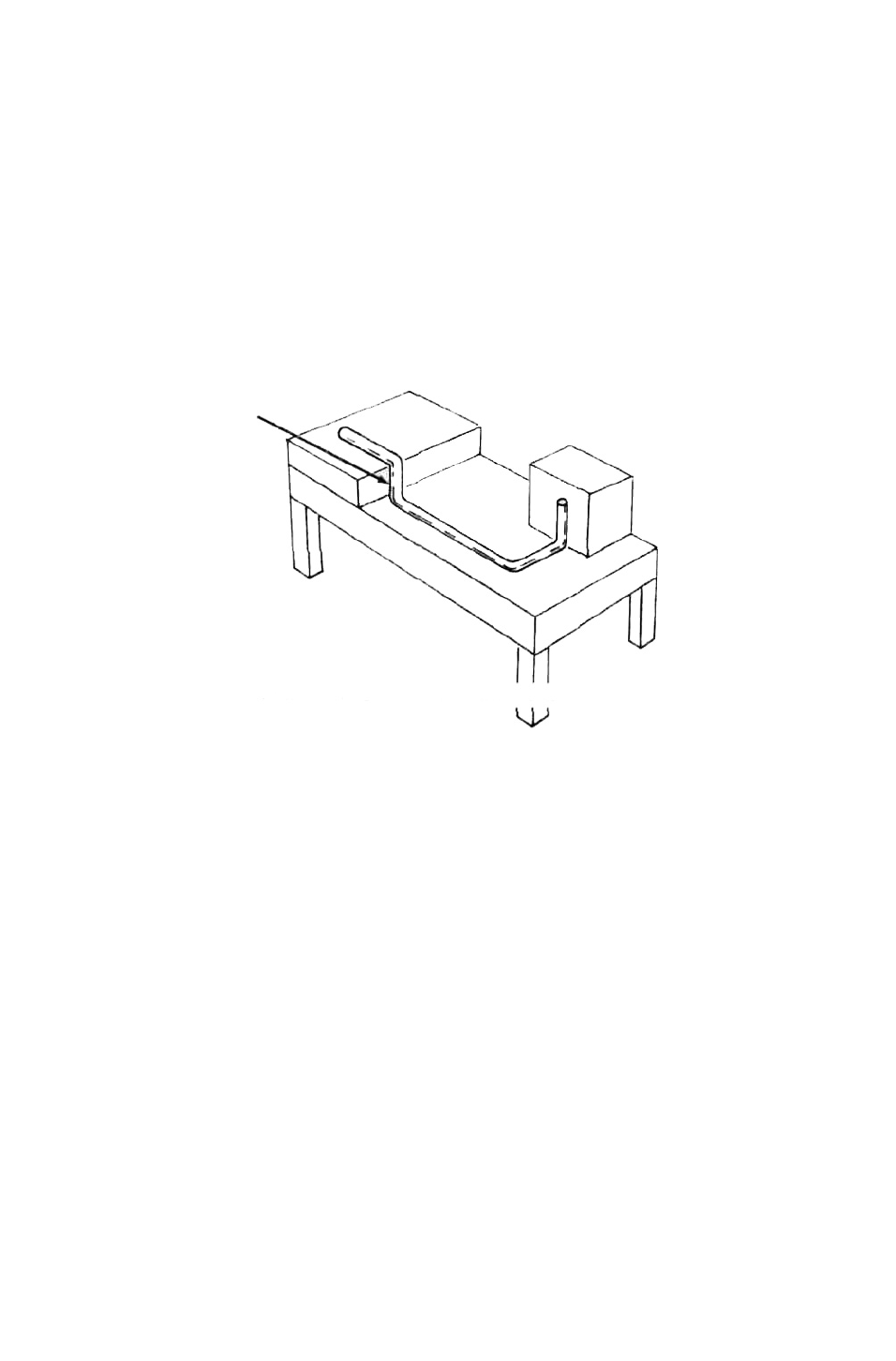

FIRST Z-BEND

FIG. 18

IMAGINARY "TABLE" AND "BLOCKS" DRAWN ONLY TO SHOW BEND DIRECTIONS

The method we have devised will take a little patience to bend the wires,

but once done, the wire length is set permanently, and the wires can all be re-

moved and replaced in seconds. Follow this method:

a Start by making the longest wires first. This way, if you accidentally

bend one too short the same piece can be used for a shorter wire later

on, saving waste. Work through to the shortest wires, doing these last.

b Leaving the wire the full 30" length, make a small normal Z-bend at

one end. See Figure 18.

c. Hook this Z-bend into the solder tab at the top of the front interplane

strut on the left side

d. Holding the wire in slight tension, make a mark on the wire (use a

felt-tip pen) where the wire passes the solder-tab at the top of the front

L. G. leg.

e Unhook the Z-bend. Bend the wire at the pen mark 90°. Now make

another 90° bend about 1/8" further along perpendicular to the long

straight section. Again, see Figure 18.

f. Cut off the wire about 1/8" along the new direction. The wire is now

made. Let's see if it fits o.k.

g See Figure 19. Hook the original Z-bend back into the tab it came

from. Now, by grasping the wire at the lower end with pliers and

twisting it, hook the other end into the second solder-tab. We are using

the torque in the wire to keep the bottom bend in the tab, and unless

the rigging wire is twisted the bottom bend cannot disengage. This

cannot happen in flight: however, removal is simply performed by

grasping the wire near the bottom with pliers and twisting until the

wire disengages.

13