Top Flite S.E.5A User Manual

Page 10

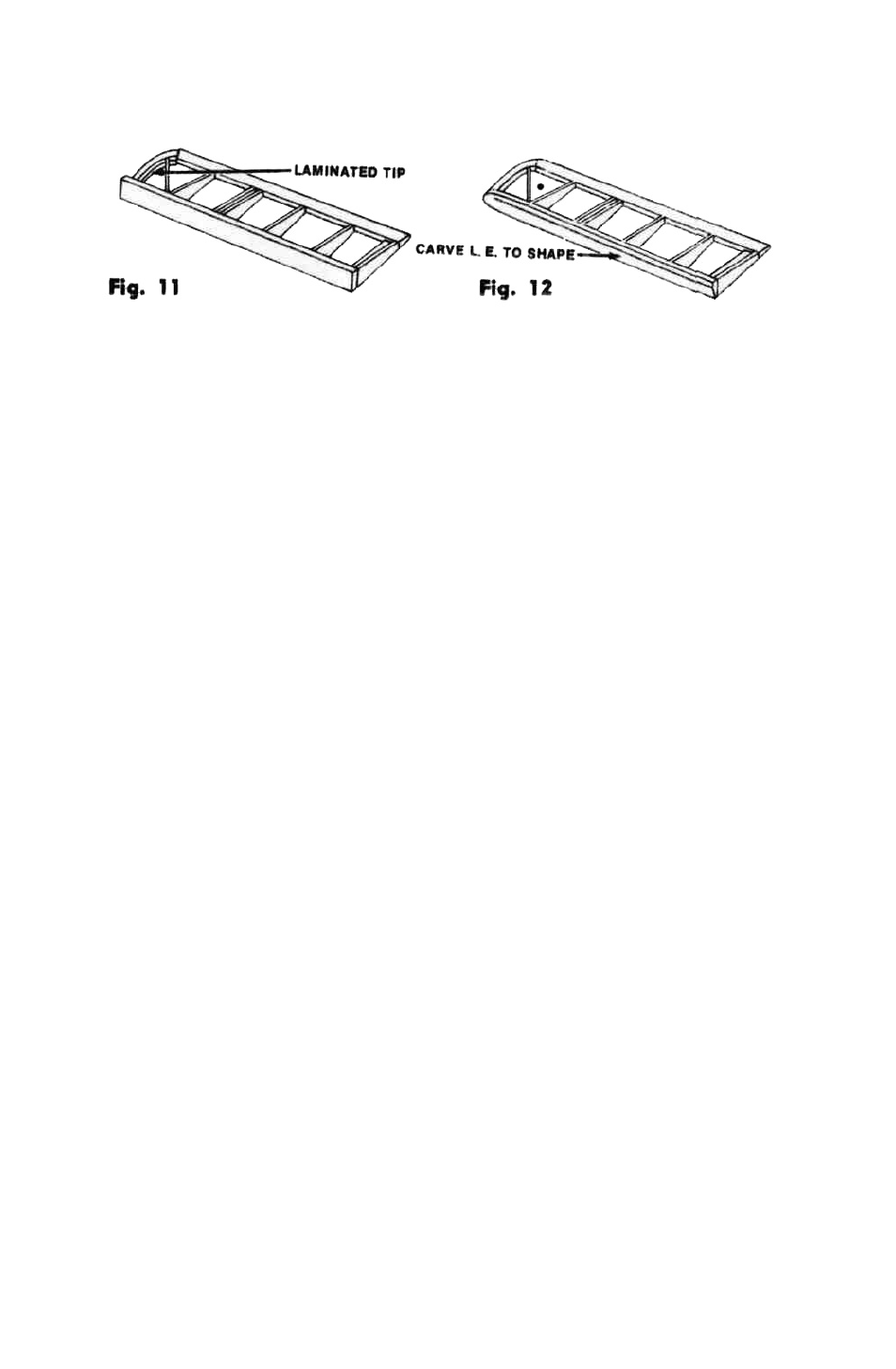

40. All four ailerons are identical—except of course that two are left and two

are right. Laminate each tip from two W-12 pieces. Construct flat on plan as in

Figure 11. When dry, carve and sand L. E. and tips to correct section: see Figure 12.

41. Hinge ailerons to bottom wing—see diagram on Plan Sheet 1. The hinges

should be held in place by toothpicks after drilling through wood and hinge material

together. Cut down the nylon aileron horns supplied to correct size indicated on

plan and glue between closely-spaced aileron ribs, using Titebond liberally to fill

holes in horn. Clamp and let dry.

42. Install nylon aileron bellcranks on W-12 (ply) bellcrank bearers. Connect

bellcranks and horns with supplied connecting links. Use small scrap of 1/16" sheet

to support covering where link exits from wing under surface.

43. Mount aileron servo in lower wing center section. It will be necessary to

make two right-angled brackets in most cases. For this purpose, two drilled metal

strips are provided which can be bent and re-drilled to suit the application. Con-

nect servo and bellcranks with 1/16" music wire pushrods, making the holes through

the ribs in the positions required by the equipment involved. Try to keep the holes

small—3/32" dia. is about right. Try out the ailerons using the radio, and do not

be satisfied with less than perfectly free and smooth movement over the whole

range of travel.

44. The top wing is made in three stages just as the lower wing, so detailed

instructions are not necessary. The only points of difference are in the slightly

altered rib-spacings, the lack of servo or bellcranks, and the center section which

is rather simpler.

When making the center-section, note that the 1/16" sheet covering extends from the

leading edge to the rear spar on the upper surface.

45. So far we have a complete fuselage and tail, with a lower wing which is

mounted in position and an upper wing not yet attached. The next job is to bring

these two items together to make a fairly complete S. E. 5A. This stage is a little

tricky, so work slowly and carefully. Study the drawing of the strut attachment

fittings on Plan Sheet 1. This nylon ball-and-socket joint is a new idea that we at

Top Flite have worked out to greatly simplify the traditionally difficult job of

rigging biplanes. This new system is far less demanding of super-accuracy than the

usual wire-bending methods. Also, assembly and dis-assembly is easier and quicker

and appearance much neater. (These fittings, incidentally, are available separately

packaged, and biplane builders will find them very useful—they will take up any

angle of strut attachment . . . sideways, backwards, forwards or combinations

of these. Ask your hobby dealer for Top Flite E-51 package).

46. From the 1/8" x 3/8" basswood strips supplied, cut 12 pieces 1-7/8" long. Drill

a 3/16" dia. hole in 8 of these 11/16" from one end and centered in the 3/8"

width. Glue these to the spars (on top of lower wing spars, and underneath upper

wing spars) so the drilled hole lines up with the first W-6 rib. Trim away ribs

and riblets slightly where required. Refer to full-size plans to check location.

The 4 undrilled pieces are glued to the forward spars in line with the drilled strips

already attached. These 4 strips will provide a covering-support for your left palm

when snapping the struts in place.

Next cut 4 pieces of 1/8" x 3/8" basswood 7/8" long, drill 3/16" in the center of each

piece and glue to the bottom of the spars in the lower wing at the dihedral-break,

again trim away ribs to suit.

9