Top Flite TOPA0905 User Manual

Page 30

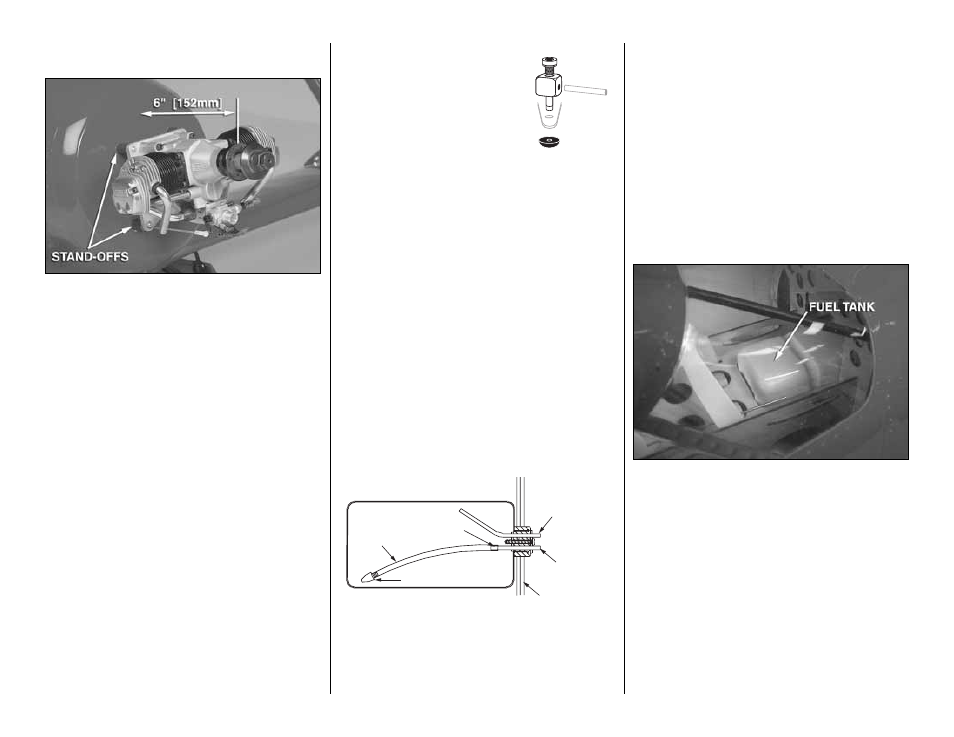

O.S. 1.60 Four-Stroke Engine

(Mounting hardware not included with kit.)

❏

1. Make stand-offs from dowels or a plywood plate

that will position the engine a distance of 6" [152mm]

from the firewall to the front of drive washer. Center

the engine so the engine will be centered in the cowl.

Make marks on the firewall for the location of the

mounting holes of the engine backplate.

❏

2. On each of the four marks drill a 7/32" [5.6mm]

hole. Install an 8-32 blind nut into each of the holes from

the back of the firewall. Install a #8 flat washer onto an

8-32 x 1" [25mm] socket head cap screw. Then, tighten

the screw into the blind nut, pulling it into the firewall.

❏

3. Mark the location where the throttle pushrod will

come through the firewall.

(Note: Because the

carburetor is an up-draft carburetor, the fuel tank is

going to have to be relocated from the location for a

two-stroke engine to the lowest point in the fuselage.

Keep this in mind when determining the location for

the pushrod. The pushrod must not conflict with the

fuel tank).

❏

4. Install the throttle servo into the servo opening

in the fuselage and drill a 1/16" [1.6mm] hole through

each of the mounting holes. Remove the servo, and

then install and remove a servo mounting screw into

each hole. Apply a couple drops of thin CA into the

holes to harden the threads. When the glue has

cured permanently mount the servo.

❏

5. Install a brass screw lock

connector, nylon retainer ring and a

4-40 x 1/8" [3mm] socket head cap

screw onto the outer hole of the servo

arm and the throttle servo arm.

❏

6. Cut the threads from an .074 x

36" [914mm] threaded rod. Bend it to fit from the

throttle servo arm to the throttle arm. When bending

the wire be sure that you have clearance between

the pushrod and any of the engine/muffler

components. Metal contact may create radio

interference. Slide the pushrod wire into the brass

screw lock connectors. Then, tighten the 4-40 x 1/8"

[3mm] socket head cap screw against the throttle

pushrod wire. Cut off any excess wire.

Install the Fuel Tank for the

O.S. 1.60 Two-Stroke Engine

Follow these instructions for any engine that

does not have an up-draft carburetor.

❏

1. Assemble the fuel tank as shown in the sketch.

When tightening the center screw be sure not to over

tighten it. You just want it snug enough to pull the

rubber stopper tight against the tank.

❏

2. Install silicone fuel tubing (not supplied) onto the

aluminum tubes from the fuel tank. The line with the

fuel clunk will feed to the fuel inlet at the needle valve

and the other will attach to the pressure tap on the

muffler. If you choose to use some kind of an external

fuel valve follow the instructions with your particular

brand of fuel valve. You can also install a third line to

the tank and use it for filling the tank. The method you

use is your choice but make your decision before

moving onto the installation of the fuel tank.

❏

3. Install the tank into the fuselage with the neck

of the tank through the firewall.

FUEL TANK

S

ILICONE

FUEL LINE

FUEL CLUNK

FUEL

PIPE

PRE

SS

URE

TAP TO

MUFFLER

TO NEEDLE

VALVE

FIREWALL

- 30 -