Top Flite TOPA0905 User Manual

Page 28

❏

8. Install the air lines to the air valve. Remove the

retaining nut from the air valve, insert the valve into

the hole in the air valve tray, and secure the valve to

the tray with the retaining nut and thread locker.

❏

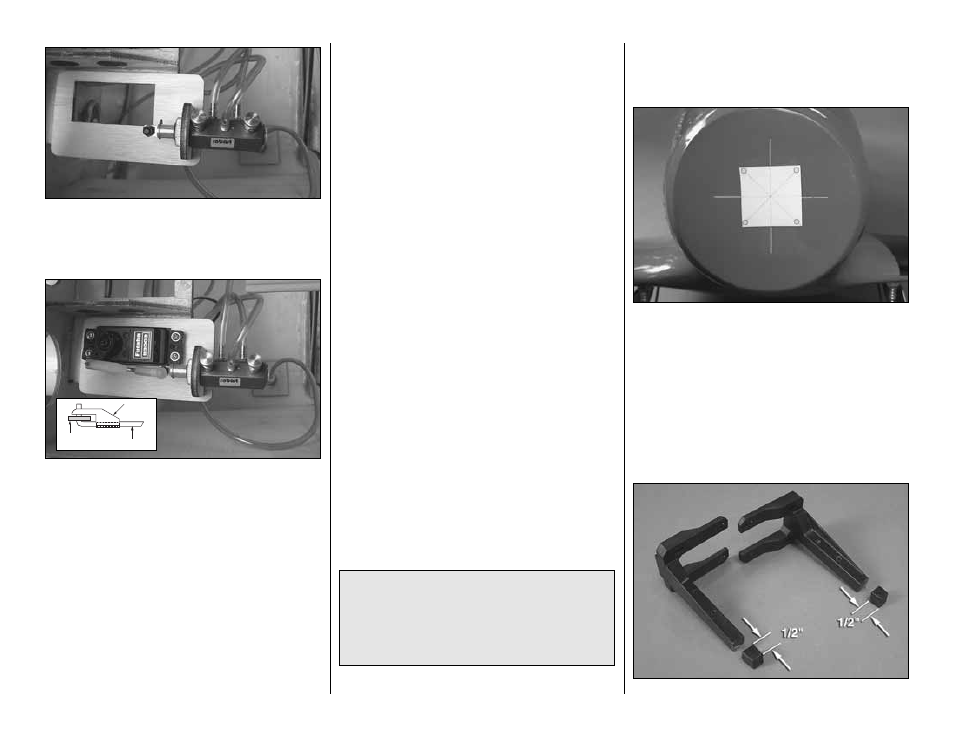

9. Place the retract servo into the tray. Drill a 1/16"

[1.6mm] hole through the servo mounting holes and

into the tray. Insert and remove the mounting screws

that came with your servo. Apply a couple of drops of

thin CA to harden the threads. Once the glue has

hardened re-install the mounting screws.

❏

10. Install a nylon ball link onto the 2-56 x 6"

[152mm] threaded rod approximately 15 turns. Then,

install the nylon ball link onto the ball. Center the air

control valve arm and center the servo. With a fine tip

marker, mark the wire where it aligns with the outer

hole of the servo arm. Make a 90 degree bend on the

mark. Cut the wire so the wire is 3/8” [10mm] in

length after the bend. Insert the wire into the servo

arm and lock it in place with a nylon Faslink.

Adjusting the Retractable Landing Gear

After connecting the air lines as explained in the

instructions that came with the Air Control kit, fill the

air tank to 100psi and try cycling the landing gear.

The landing gear should cycle up and down freely. If

they do not, here are some troubleshooting tips.

The gear does not move up or down:

Check to be sure the control screws on the variable

rate valve are open.

The landing gear moves up and down but

is not smooth:

When mounting the landing gear onto the landing

gear rails, it is important that the rails are exactly

parallel to one another. If not, when you tighten the

screws the mounting flange of the gear mechanism

can twist slightly. Try loosening the mounting screws

a little and try cycling the landing gear again. If the

gear now works, re-tighten the screws one at a time,

cycling the gear after each screw is tightened. When

you find out which screw is pulling down too hard on

the mounting flange, slip a shim under the mounting

flange and then re-tighten the screw.

One of the landing gear goes up while the

other goes down:

Most likely you have crossed one of the air lines.

INSTALL ENGINE & THROTTLE SERVO

O.S. 1.60 Two-Stroke Engine

❏

1. On page 43 of this manual you will find the

engine mounting template. Cut out the template from

the manual and tape it to the firewall, aligning the

lines of the template with the lines on the firewall.

❏

2. On each of the four marks drill a 7/32" [5.6mm]

hole. Install an 8-32 blind nut into each of the holes

from the back of the firewall. Install a #8 flat washer

onto an 8-32 x 1" [25mm] socket head cap screw.

Then, tighten the screw into the blind nut, pulling it

into the firewall. Do this for all four blind nuts.

Did you know…

Early in World War II, the need

for a compact executive-type transport or courier

aircraft became apparent and in 1942 the United

States Army Air Force ordered the first of 270

Model 17s for service within the United States and

overseas as the UC-43.

- 28 -

FA

S

LINK

2-56 (.074")

PU

S

HROD WIRE

S

ERVO

HORN