Carrier 42 SERIES User Manual

Page 23

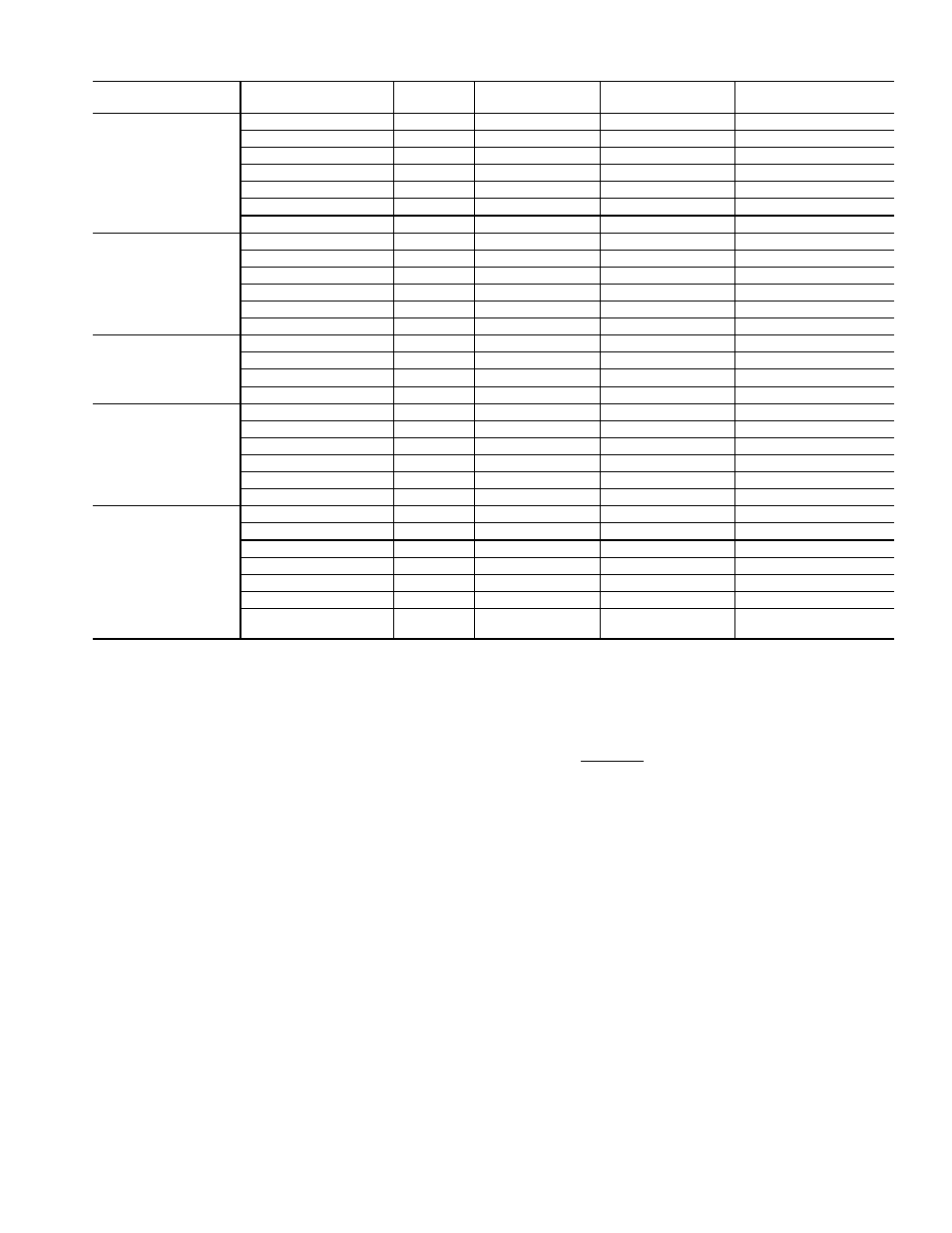

Table 1 — Acceptable Field-Furnished Pneumatic Valves

MANUFACTURER

VALVE NUMBER

TYPE

MODE

SIZE (in.)

(OD Male Flare)

CAPACITY

(CV) RATING

HONEYWELL

VP517A

3-WAY

MIXING

7

⁄

8

3.0, 4.0, 6.3

VP522A&B

3-WAY

SEQUENCING

5

⁄

8

or

7

⁄

8

1.6/2.5 or 2.5/3.5/4.0

VP526A

3-WAY

MIXING

5

⁄

8

1.6, 2.5

VP527A

2-WAY

N.O.

1

⁄

2

0.63, 1.0, 1.6

VP513A

2-WAY

N.O.

5

⁄

8

or

7

⁄

8

2.5, 4.0

VP513B

2-WAY

N.C.

5

⁄

8

1.0, 1.6, 2.5

VP531A

2-WAY

N.O.

5

⁄

8

or

7

⁄

8

(ODS)

1.6, 2.6, 3.3

JOHNSON

SERVICE

V4332

3-WAY

MIXING

1

⁄

2

1.2, 2.0

V4334

3-WAY

MIXING

5

⁄

8

4.7

V4440

3-WAY

SEQUENCING

1

⁄

2

1.4, 2.4

V4440

3-WAY

SEQUENCING

5

⁄

8

4.1, 4.7

V3766

2-WAY

N.O.

1

⁄

2

1.0, 1.7, 3.2

V3966

2-WAY

N.C.

1

⁄

2

1.7, 3.2

BARBER-

COLEMAN

VK9312

3-WAY

MIXING

5

⁄

8

2.0, 4.0

VK9332

3-WAY

SEQUENCING

5

⁄

8

1.7, 2.4, 4.0

VK9212

2-WAY

N.O.

5

⁄

8

0.4, 1.3, 2.2, 3.3

VK9222

2-WAY

N.C.

5

⁄

8

0.4, 1.3, 2.2, 3.3

MCC

POWERS

VP656-0011, 10, 09

3-WAY

MIXING

1

⁄

2

1.5, 2.5

VP658-0004, 5

3-WAY

DIVERTING

1

⁄

2

2.5

VP658-0050, 51

3-WAY

SEQUENCING

1

⁄

2

1.5, 2.5

VP658-0004, 5

2-WAY

N.O.

1

⁄

2

1.0, 2.5

VP656-0002, 4

2-WAY

N.O.

1

⁄

2

0.9, 2.1

VP656-0012

2-WAY

N.C.

1

⁄

2

2.1

ROBERTSHAW

2582 (V8200)

2-WAY

N.O.

1

⁄

2

0.4, 0.6, 1.0, 1.6

2583 (V8300)

3-WAY

MIXING

1

⁄

2

1.6

2561 (V6101)

2-WAY

N.C.

1

⁄

2

,

5

⁄

8

1.2, 2.2, 4.1

2561 (V6102)

2-WAY

N.O.

1

⁄

2

1.0, 1.6

2563 (V6300)

3-WAY

MIXING

1

⁄

2

1.6

2563 (V6301)

3-WAY

MIXING

5

⁄

8

2.5

2569 (V6900, 01)

3-WAY

SEQUENCING

1

⁄

2

,

5

⁄

8

,

7

⁄

8

.6, 1.0, 1.1, 1.6,

2.5, 3.2, 2.4, 4.0, 4.5

CV

— See Note 5.

N.C. — Normally Closed

N.O. — Normally Open

OD

— Outside Diameter

NOTES:

1. This reference table lists valves that are acceptable because of

capacity and piping connection type. Actual valve selection for spe-

cific mode (N.O. or N.C.) and capacity rating (CV) to meet jobsite

conditions must be made by field personnel.

2. Valve size (

1

⁄

2

-,

5

⁄

8

-, and

7

⁄

8

-in. OD) designates the matching tub-

ing size.

Use price page package 18-2 or 18-4 for selecting

1

⁄

2

-in. or

5

⁄

8

-in.

OD valves. Use price page package 18-3 or 18-5 for

7

⁄

8

-in. OD

valves.

3. The

1

⁄

2

-in. and

5

⁄

8

-in. OD valves are used primarily on 42C (ceiling)

and 42V (vertical) room fan coil units. The

7

⁄

8

-in. OD valves are

recommended for use on 42D (ducted) units.

4. Flare connections are 45° SAE flare with body threaded for stand-

ard flare nuts.

5. The CV capacity rating is the gpm flow through a valve at 1.0 psi

pressure drop.

EXAMPLE: A 2.5 CV valve has a flow of 2.5 gpm at 1.0 psi pres-

sure drop.

As flow changes, pressure drop can be determined by the

formula:

Actual gpm

2

P =

CV

6. Restrictions imposed by limited piping enclosures often require that

the valve manufacturer’s recommendation for obstruction free serv-

ice clearances be waived. Service/isolation valves normally speci-

fied will permit removal of the entire pneumatic valve for field serv-

ice if necessary.

7. Certain combinations of piping accessories and control valves have

proven unacceptable in the past, therefore the factory must re-

serve the right of review for final acceptance.

8. Consult factory on all applications involving valves with thermo-

static actuators or built in pneumatic thermostats.

23