Shortening the sensor, Sentry 6510 capacity monitor – TeeJet SENTRY 6510 User Manual

Page 11

9

990-630-EN R0

Sentry 6510 Capacity Monitor

On some combine harvesters, it may not be possible to fit the sensor in the recommended position due to placement of other parts, such as

an adjustment handle. In these cases, the sensor can be mounted higher or lower than 50 mm under the sieves. In any case, the centre of

the sensor must not be higher than the edge of the sieve, or lower than 100 mm under the sieve.

Figure 11: Alternate sieve sensor bracket placement

Once the position is determined, weld or bolt the brackets to the sieves so that they are stable and do not shake.

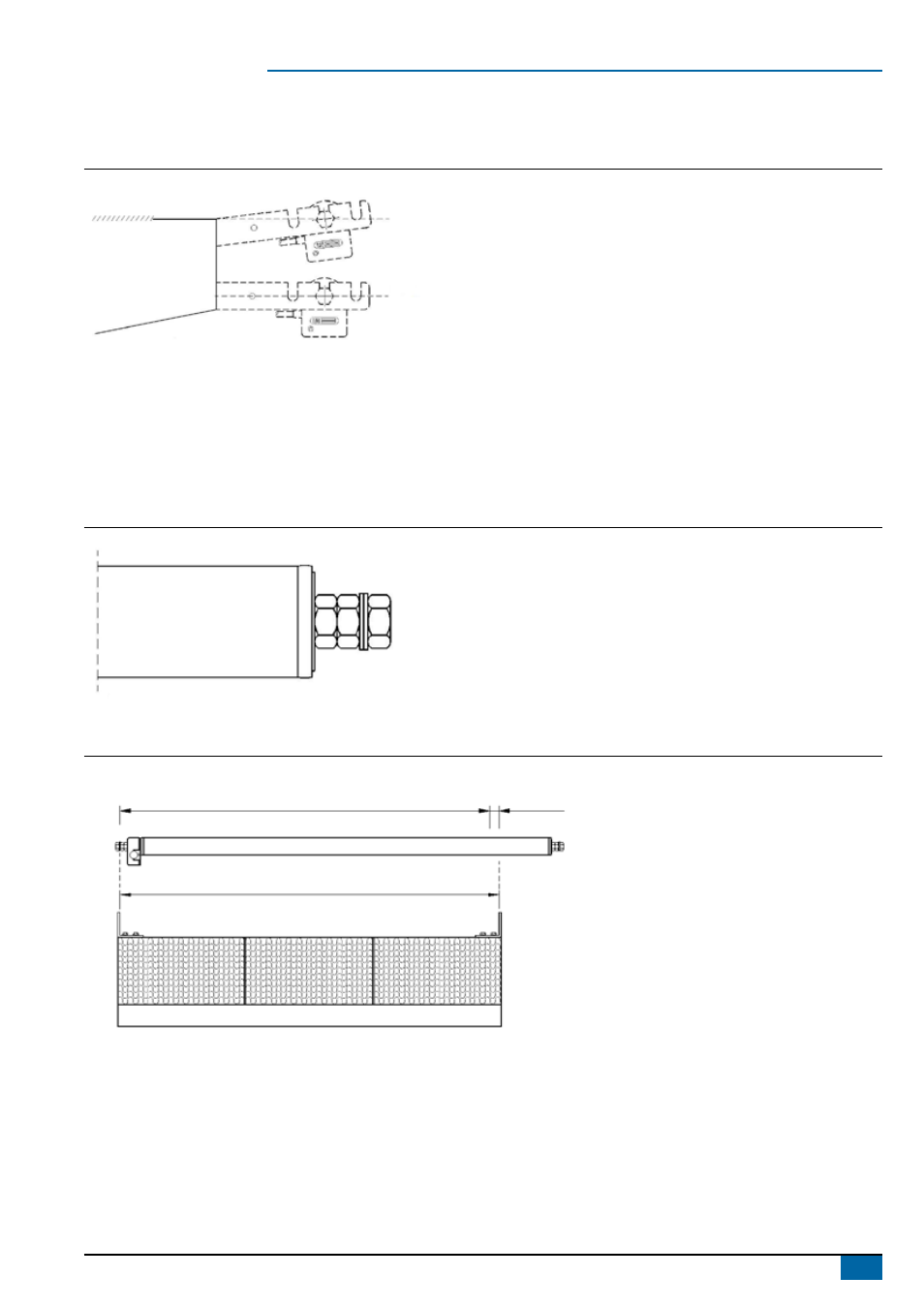

Shortening the sensor

The steel tube can be shortened to the distance between the two brackets.

1. Loosen all of the nuts and remove the rubber bung opposite the plug.

2. Loosen the Allen screw and remove the plastic spacer from the tube.

Figure 12: Sensor tube nuts

3. Measure the distance between the brackets (x), and subtract 22 mm, to learn the distance between the two washers (L).

Figure 13: Sensor tube length calculation

4. Cut the tube with a hacksaw.

NOTE: To avoid damaging the tube, do not use a vice when cutting the tube. Remove all metal shavings from the tube before replacing the

rubber bung.

5. Position the plastic spacer approximately 5 mm from the end of the bolt in the rubber bung.

6. Replace the rubber bung so that approximately 5 mm of the bung protrudes from the tube.

22 mm

x

L

0 mm

100 mm