744a sprayer control, Input power cable, Pressure gauge – TeeJet 744A Sprayer Control User Manual

Page 11

www.teejet.com

8

744A Sprayer Control

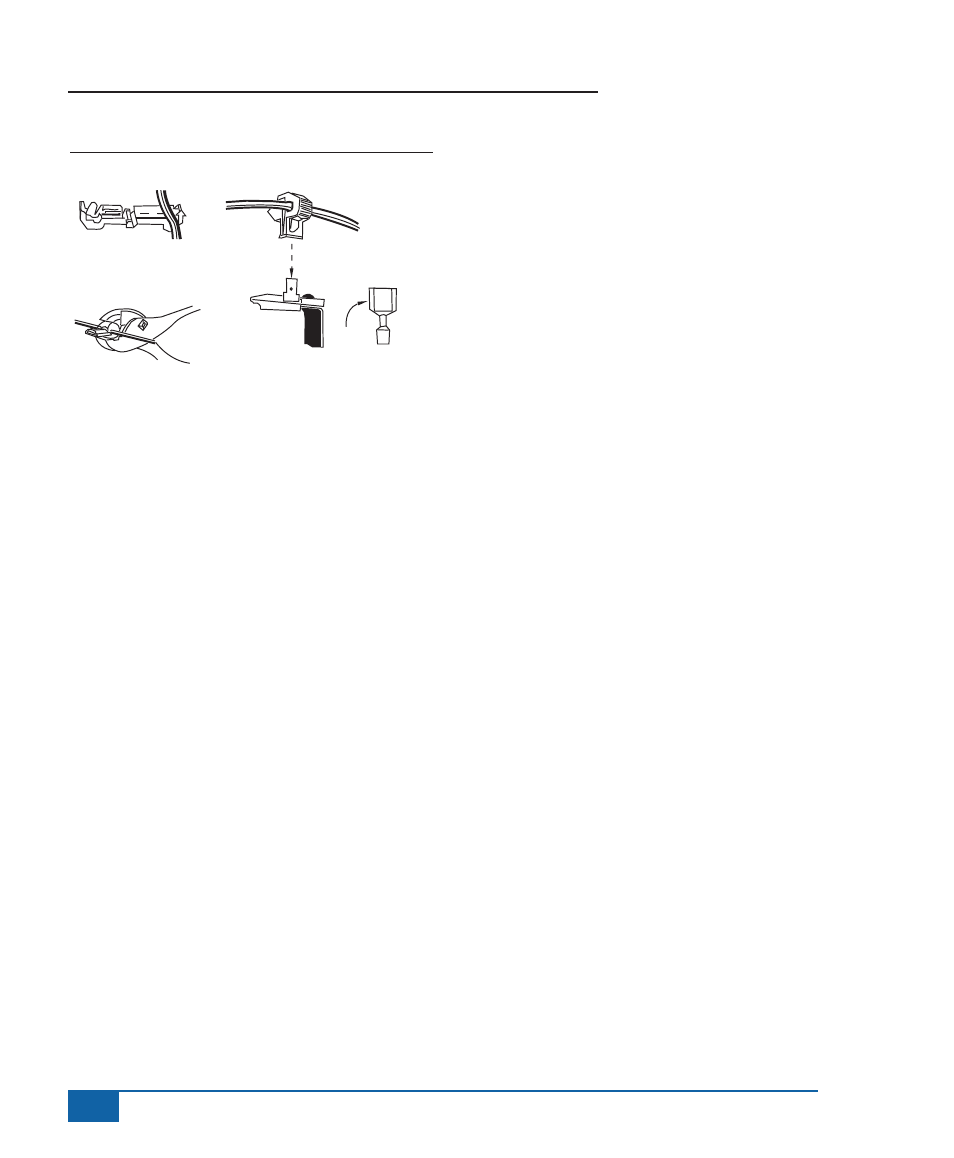

Figure 2-2: Figure 2-2: T-Tap Connector Assembly

Step A

Step B

Step C

To Terminal of

144 Directo Valve

Ball

Valve

Connector

Input Power Cable

The Input Power Cable consists of three wires. The

red wire should be connected to a 12 Volt power

supply within the cab of the vehicle (i.e., ignition

switch). If the power source is located outside of the

cab, the power cable should exit the cab through

the same 1.0” (3.0 cm) diameter hole as the output

control cable. The blue wire should be connected

to the headlight system of the tractor. This can

be accomplished by connecting the blue wire to

the auxiliary terminal of the headlight switch or by

splicing into the wire connected to the headlight.

The black wire is the negative lead and should be

connected to a good chassis ground.

Plug the input power cable into the power cable

socket on the back of the 744A console. Turn the

vehicle ignition switch to the “Run” position. If the

wiring has been connected properly, the boom

section indicator lights should illuminate when the

boom section switches are toggled. The gauge light

should appear when the headlights are illuminated.

Pressure Gauge

The tubing for the pressure gauge is supplied

as part of the wiring harness. To avoid chemical

leakage into the vehicle cab, the tube coupler

should be installed outside of the vehicle cab. If a

gauge isolator is used with the system, it should be

installed in place of the coupler, also outside of the

vehicle cab.

The pressure gauge should be checked for

accuracy each season. If the unit is equipped with

a liquid-filled gauge and it does not read accurately,

the gauge may need to be vented. To vent the

gauge, remove the four screws in the back of the

sprayer control housing and lift off the back. The

rear of the gauge will be exposed. To vent the

gauge, clip off the nib of the rubber plug in the back

of the gauge or puncture it with a needle. Once the

gauge has been vented, do not store the sprayer

control on its back as this may cause a loss of

fluid from within the gauge. If further inaccuracy

is suspected at 0 PSI and a gauge isolator is

being used, the isolator line may need to be bled

according to the instructions furnished with the

gauge isolator.