744a sprayer control, Chapter 2 - installation mounting bracket, Output control cable – TeeJet 744A Sprayer Control User Manual

Page 10: 744a-3 unit

www.teejet.com

7

744A Sprayer Control

CHAPTER 2 - INSTALLATION

MOUNTING BRACKET

1. Make sure all switches on the 744A Sprayer

Control are turned to the “Off” position.

2. Determine the best location for the 744A Sprayer

Control in the vehicle cab according to the

following guidelines:

• pressure gauge should be readily visible

• switches should be within easy reach

• controller bracket should rest on a flat surface

• 12 volt DC power source must be accessible

(maximum draw 10 amps)

3. Determine the proper routing for power cables

and pressure tube:

• away from operators’ movement area

• away from moving parts

• away from sharp objects

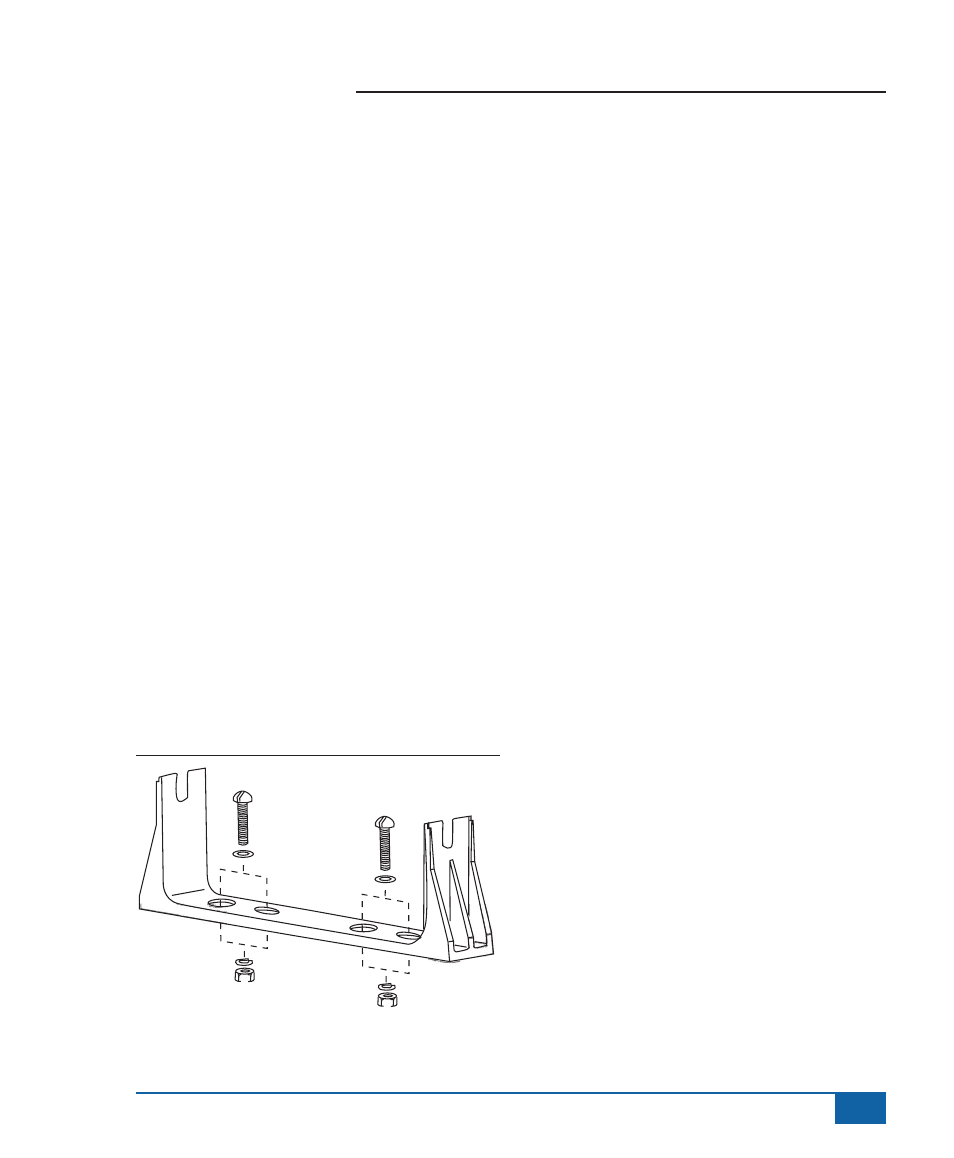

4. Install the mounting bracket using ¼” (6.4mm)

drill, machine screws, nut, washers, and lock

washers as illustrated below. Attach the control

housing assembly to the mounting bracket using

the console adjusting knobs and washers.

Figure 2-1: Mounting Bracket

OUTPUT CONTROL CABLE

Cut a 1.0” (3.0 cm) diameter opening used to feed

the output control cable from the interior of the

tractor cab to the boom control valves. Make sure

the hole has no burrs or sharp edges that could

damage the wires.

744A-3 Unit

6 wires from the output cable are used to control a

three-section boom.

• Orange (Right) Yellow (Center) Green (Left) –

connect to 144A Valves. When using a

*344AEC Ball Valve, connect to the white wire.

• **Black – connect to other terminal on 144A

Valves. When using the *344AEC Ball Valve,

black is not connected.

• Red and Brown – connect to red and black

wires on the Regulator Valve (244, 344AE-PR,

or 344AE-RL).

*When using 344AEC DirectoValve® Ball Valves, connect black

wire(s) and red wire(s) using the Valve End and Battery End

Cables (supplied only when Ball Valve Kits are purchased) to an

uninterrupted power supply such as the battery.

**The black ground wire for the control cable is not supplied

with connectors attached. The T-Tap connectors are supplied

separately and should be attached as per Figure 2-2.

WARNING!: Do not plug the control cable into the

control box until it has been fully connected

to the control valves. Doing so may allow the

unconnected leads to short out.