Applications – ultrasonic insertion – Sonics H540 E User Manual

Page 33

A P P L I C A T I O N S – U L T R A S O N I C I N S E R T I O N

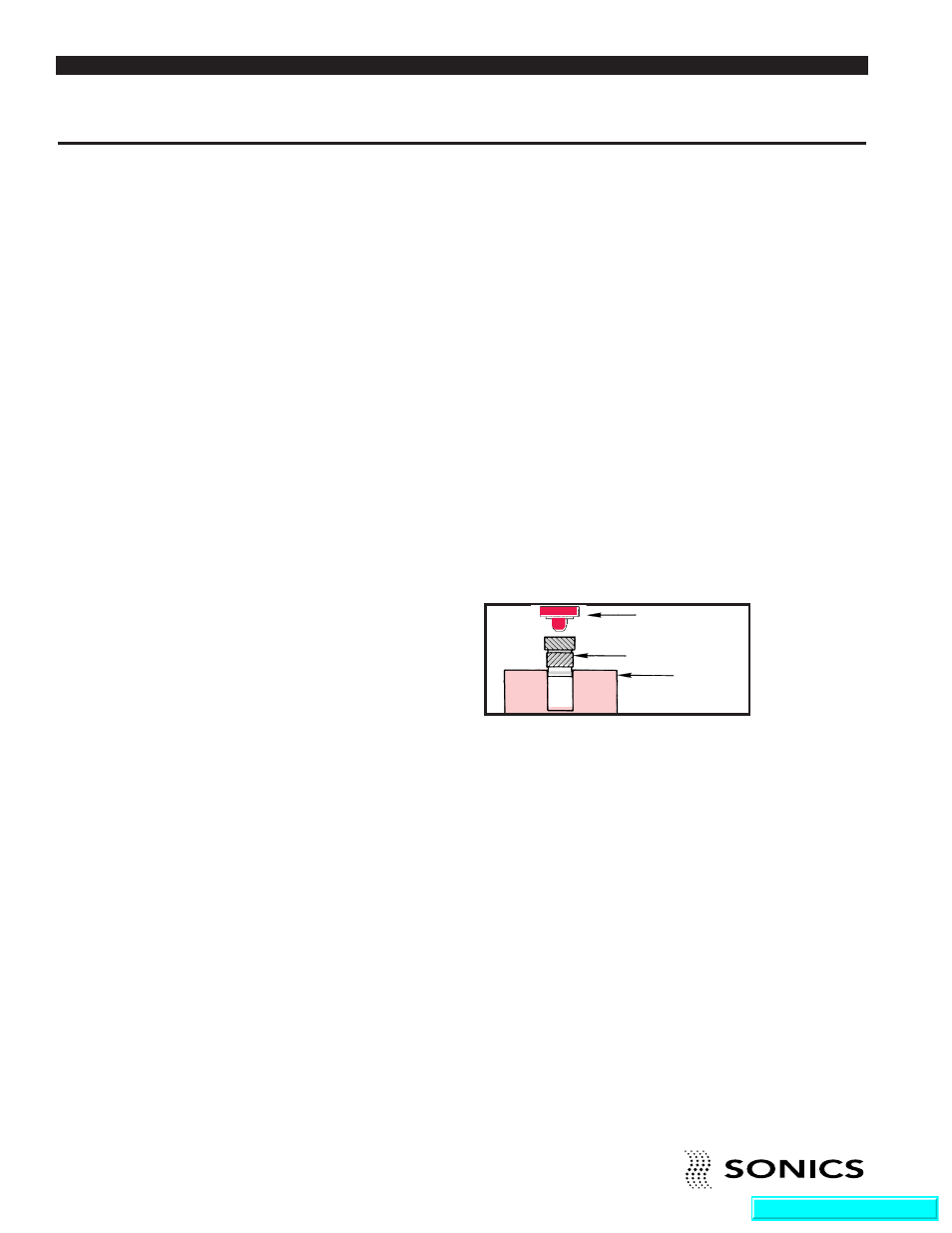

Ultrasonic insertion involves a metal insert to be placed in a cored or drilled

hole that is slightly smaller than the insert. This hole provides a certain

degree of interference and also serves to guide the insert into place. The

vibrating ultrasonic horn contacts the insert and the ultrasonic vibrations

travel through the insert to the interface of the metal and plastic. Heat,

generated by the insert vibrating against the plastic, causes the plastic to

melt, and as the horn advances, the insert is embedded into the component.

The molten plastic flows into the serrations, flutes, or undercuts of the inserts

and, when the vibrations terminate, the plastic resolidifies and the insert is

securely encapsulated in place. Inserts can be ultrasonically installed in most

thermoplastics.

Ultrasonic insertion provides the high performance strength values of a

molded-in insert while retaining all of the advantages of post-molded

installation. Some of the advantages of ultrasonic insertion over other

methods include rapid installation, minimal residual stresses in the

component following insertion, elimination of potential mold damage,

reduced mold fabrication costs and increased productivity as a result of

reduced mold cycle times.

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

32

I N S T R U C T I O N M A N U A L • H A N D H E L D W E L D E R S

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

PLASTIC

INSERT

HORN

Go To Top Of Document