Applications – staking, Standard flared stake – Sonics H540 E User Manual

Page 29

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

28

I N S T R U C T I O N M A N U A L • H A N D H E L D W E L D E R S

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

A P P L I C A T I O N S – S T A K I N G

Ultrasonic staking, also referred to as ultrasonic “heading” or “riveting”,

controls the flow of the molten plastic used to capture or retain another

component in place. Ultrasonic staking provides an alternative to welding

when the two parts consist of dissimilar materials that cannot be welded or

when simple mechanical retention of one part relative to another is

inadequate (i.e. as distinct from molecular bonding). A common application

is the attachment of plastic to metal. Typically a metal part, with location

holes, is placed over a plastic part with molded bosses. The horn tip is then

pressed against the plastic boss and the vibratory motion creates friction

and localized heating. As the boss melts, the light pressure from the horn

forms a head to a shape determined by the horn tip configuration. When the

vibrations stop, the plastic material solidifies, and the dissimilar materials are

fastened together.

With staking, tight assemblies are possible because mating parts are

clamped under pressure of the horn until the rivet head solidifies. There is no

elastic recovery as is the case with heat staking or cold forming. A major

advantage of ultrasonic staking over heat staking is that the ultrasonic

staking tip remains relatively cool during the process, forming a clean head

with no sticking or stringing during assembly.

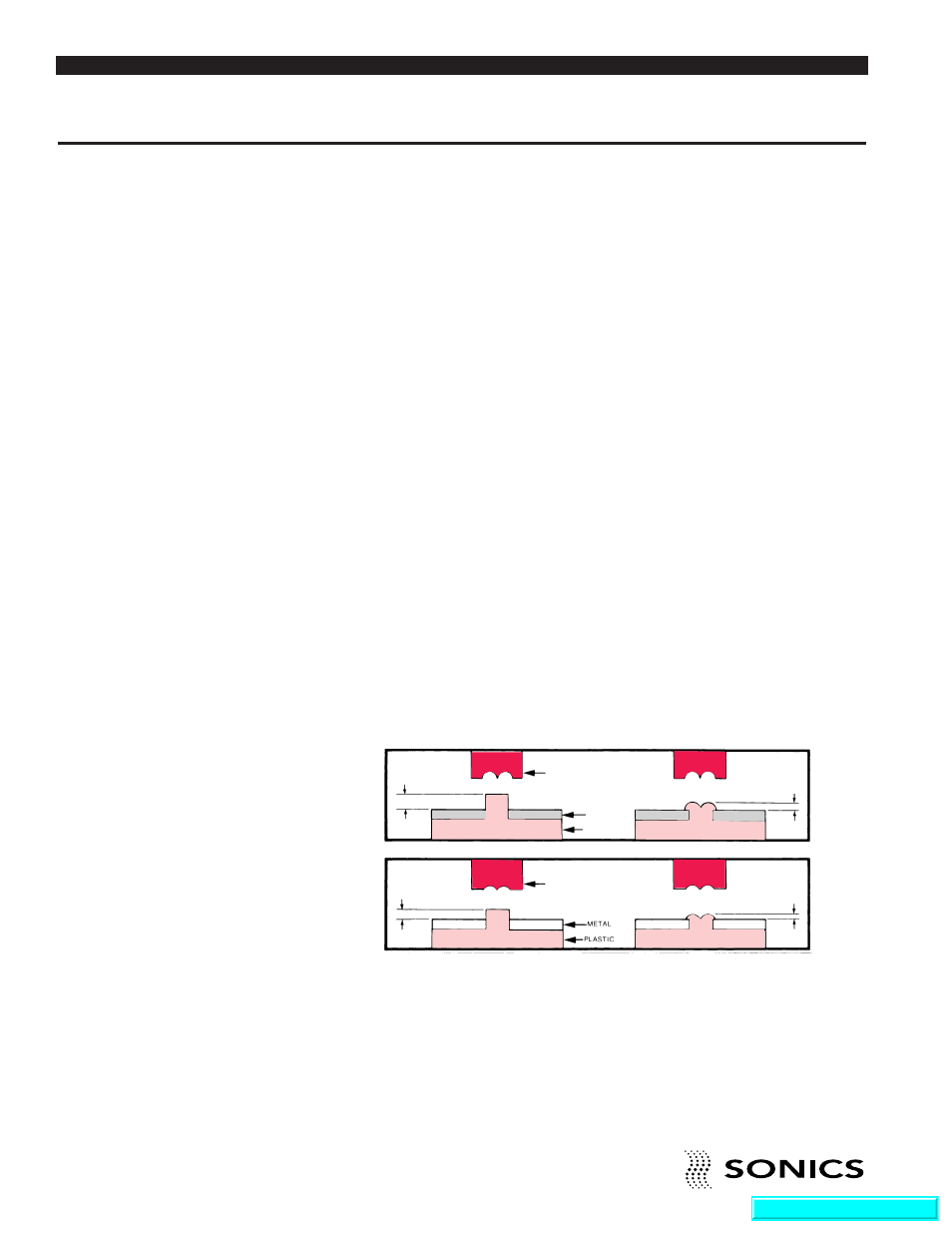

STANDARD FLARED STAKE

The standard flared stake satisfies the requirements of most applications.

This stake is recommended for bosses with an O.D. of 1⁄16 inch (1.6 mm) or

larger, and is ideally suited for low density, nonabrasive amorphous plastics.

BEFORE

HIGH PROFILE

AFTER

.6d

.5d

METAL

PLASTIC

HORN

HORN

BEFORE

LOW PROFILE

AFTER

1.6d

.25d

d

2d

Go To Top Of Document