Spherical stake, Hollow stake, Knurled stake – Sonics H540 E User Manual

Page 30: Go to top of document

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

I N S T R U C T I O N M A N U A L • H A N D H E L D W E L D E R S

29

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

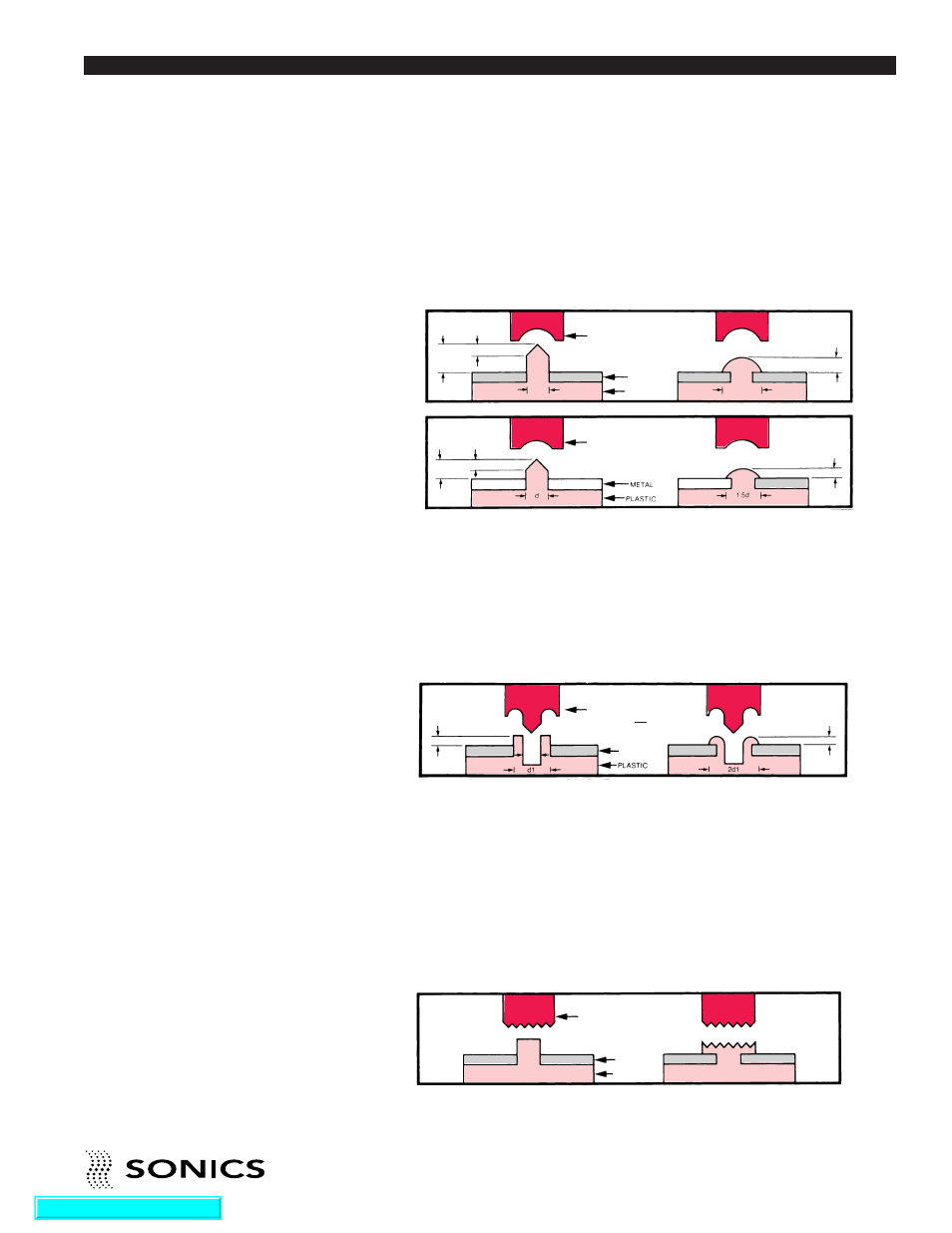

SPHERICAL STAKE

The spherical stake is preferred for bosses with an O.D. less than 1⁄16 inch

(1.6 mm). It is also recommended for rigid crystalline plastics with sharp

highly defined melting temperatures, for plastics with abrasive fillers, and for

materials that degrade easily.

HOLLOW STAKE

Bosses with an O.D. in excess of 5⁄32 inch (4 mm) should be made hollow.

Staking a hollow boss produces a large, strong head without having to melt

a large amount of material. Also, the hollow stake avoids sink marks on the

opposite side of the component, and enables the parts to be reassembled

with self-taping screws, should repair and disassembly be necessary.

KNURLED STAKE

The knurled stake is used in applications where appearance and strength are

not critical. Since alignment is not an important consideration, the knurled

stake is ideally suited for high volume production, and is often recommended

for use with a hand held ultrasonic spot welder.

Knurled tips are available in a variety of fine, medium and course

configurations.

BEFORE

HIGH PROFILE

AFTER

2.12d

.75d

METAL

PLASTIC

HORN

d

2d

BEFORE

LOW PROFILE

AFTER

.8d

.375d

HORN

.5d

.5d

BEFORE

AFTER

METAL

HORN

H=1.6 d2

.5d1

.5d

d2 =

d1

2

d2

BEFORE

AFTER

METAL

PLASTIC

HORN

Go To Top Of Document