Warning – Slant/Fin VHS-180 User Manual

Page 30

V

ICTORY

II

VHS Models

30

C. Piping

Check the following:

1. Water piping and accessories for leaks. Slightest

leaks should be corrected.

2. System to be full of water and pressure to remain

stable at correct setting on gauge.

3. Air-control system. Noise and air binding in radia-

tion should not occur.

4. Low water cutoff for operation (see instructions fur-

nished with unit).

D. Boiler Room Air Supply

Check air vents for continued positive supply of air as

required. Air needs are greatest in cold weather. Air

vents must be open and free of obstruction.

WARNING: The flow of combustion and ventilating air to

the boiler should not be obstructed.

2. Inspection During Heating Season

A. Check water pressure regularly and add water slowly

to system when needed. If much water is added, vent-

ing may be necessary. Regular loss of water from boil-

er system may indicate either a system leak, or a

faulty air control system, or a faulty automatic fill valve.

B. Check venting system. See “Venting System Regular

Inspection” on Page 14.

C. Check condensation drain trap to be full of water.

Check for deterioration of the tubing. Check that the

trap is not plugged.

3. Annual Inspection and Cleaning

The following must be done by a competent serviceperson

to help insure safe and reliable operation:

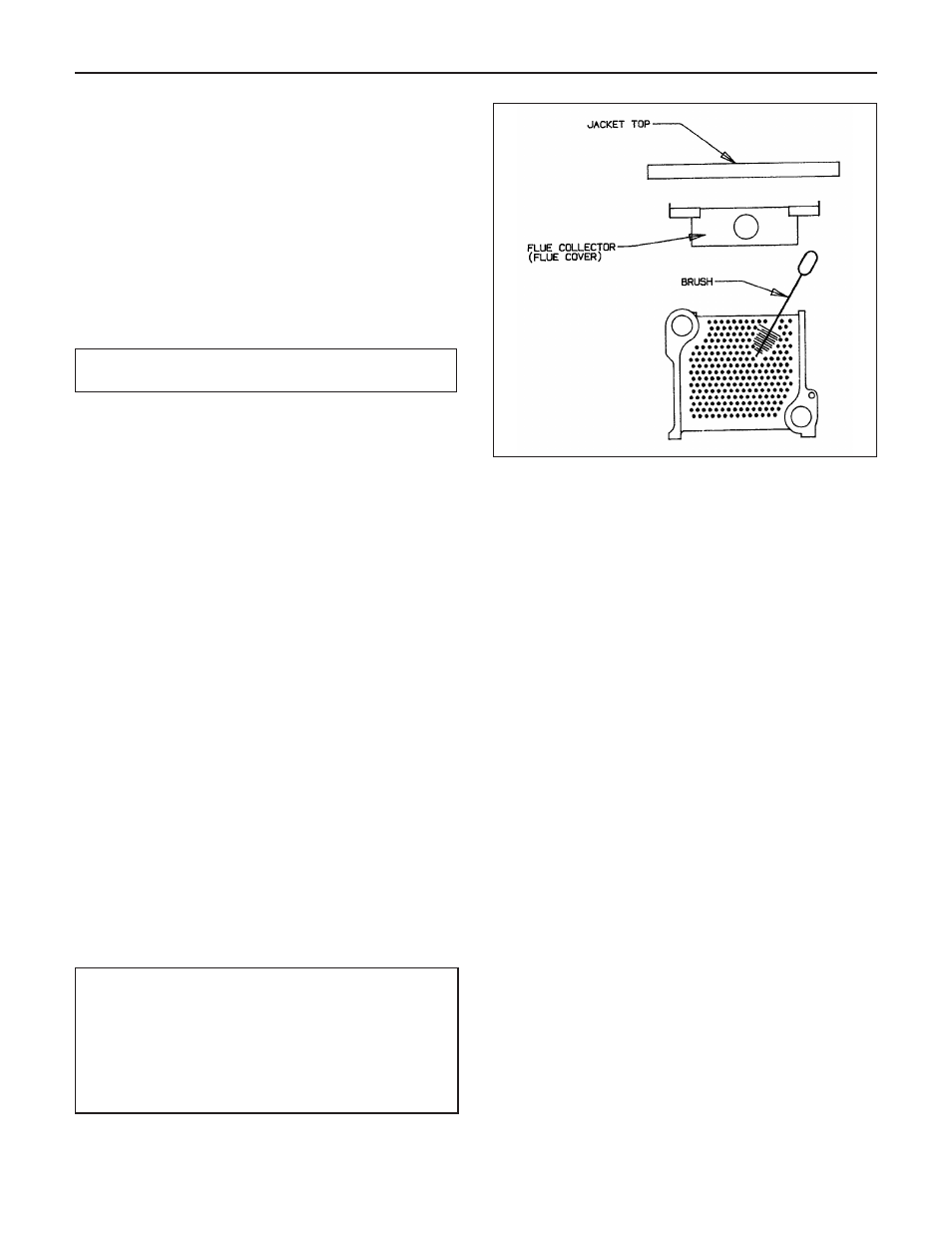

A. Flue passage cleaning

See Figure 27. It is suggested that paper be placed on

burners to collect any foreign material in cleaning

flues.

1. Remove control box (see instruction under “Safety

Check”. See Figure 24).

2. Remove jacket top.

3. Remove inducer assembly.

4. Remove flue collector.

5. Use wire brush to clean flue passages.

6. Replace flue collector and re-seal with furnace

cement.

7. Replace inducer assembly, jacket top and control

box.

8. Remove and dispose of paper and accumulated

material.

B. Cleaning of burners

If burners’ surfaces are not clean, or uneven flame

indicates plugged burner parts, remove and clean

burners.

1. Remove pilot gas line at gas valve.

2. Disconnect pilot burner assembly from pilot bracket.

3. Lift burner and remove burner from orifice.

4. Clean burners. To clean burners, run a clean flue

brush up the tube until all foreign matter is

removed.

5. Replace burners, pilot assembly, ignitor and sensor

wires.

6. Adjust burners and pilot assembly.

C. Re-check of input gas rate of burners. See “Burner

Adjustment” on Page 27.

D. Re-adjusting for best flame characteristics of main

flame and pilot burner flame. See “Burner Adjustment”

on Page 27.

E. To prolong the life of inducer motor, lubricate with

Anderol 465 or SAE 20 motor oil annually. Turn off

power and place 4-6 drops of above mentioned lubri-

cate in each of two oil holes. Lubricate circulator per

manufacturer’s instruction. DO NOT over oil any motor.

Figure 27.

WARNING:

The ceramic combustion chamber in the burner box

contains crystalline silica.

Wear proper dust mask and gloves when servicing

combustion chamber or burners.

Crystalline Silica has been identified as a carcinogen or

possibly carcinogenic to humans.