Operation (continued) – Shellab SMO5HP-2 User Manual

Page 18

18 |

P a g e

OPERATION (CONTINUED)

Note: The accuracy of the calibration process is limited by the accuracy of your reference

temperature device.

The difference

between the reference device and oven’s display is called an offset.

Examples of offsets:

Reference Sensor

Reading

Watlow Temp.

Display

Offset

Value

152°C

150°C

2

148°C

150°C

-2

Note:

If the door was opened to check the reference device’s reading, allow the oven

temperature ten minutes to stabilize before entering the offset.

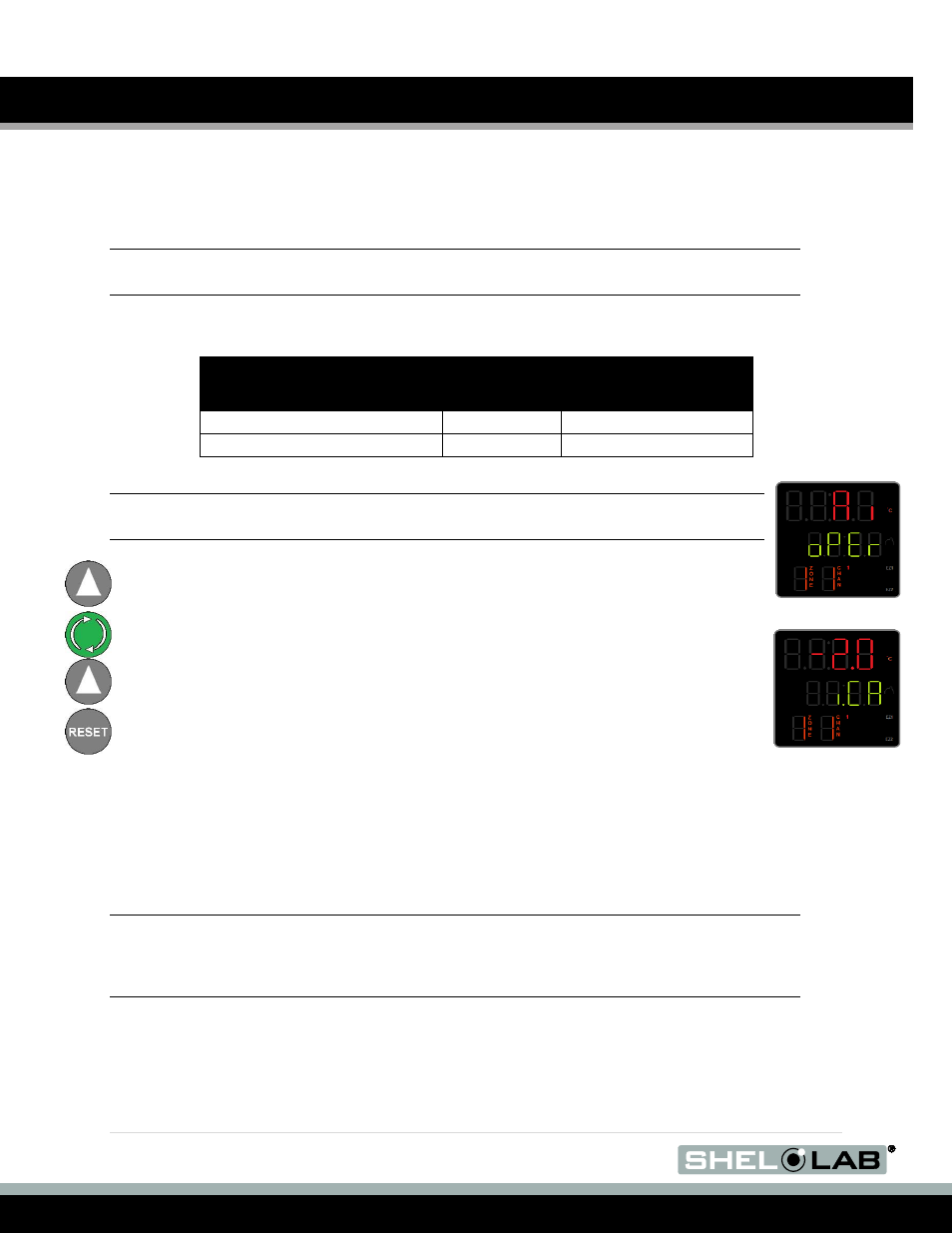

9. Enter the temperature offset into the Watlow Controller. To do so, push and hold both

the Up and Down Arrow Button simultaneously for three (3) seconds or until

“Ai”

appears in the Upper Display and

“oPEr” appears in the Lower Display.

10. Push the green Advance Button repeatedly unit

“i.CA” appears in the green middle

display and a number value shows in the red top display.

11. Adjust the number value in the top display using the Up or Down Arrow Buttons to

match the offset value.

12. Once the Offset Calibration Number is entered, push the Reset Button repeatedly to

exit the calibration, save the set point, and return to the Home Page.

13. Wait for a half hour, then compare the reading of the reference device and the Watlow

Controller. Enter an offset if the readings are still different and fall outside your laboratory

protocol range.

14. If the temperature readings of the display and the reference device still do not fall close

enough to be acceptable by your laboratory protocol after three calibration attempts,

contact Sheldon Technical Support for assistance.

Note: After calibrating the oven to your process or application temperature, set the Over

Temperature Limit to 5

°C above the process / application’s set point. If you will be running a

programed heating profile, set the Over Temperature Limit to 5

°C above the profile’s highest

set point.

End of Procedure