First use burn in, Calibrating the unit, Burn-in – Shellab SMO5HP-2 User Manual

Page 17: E 17, E 17.), G.17), Operation (continued)

17 |

P a g e

OPERATION (CONTINUED)

F

IRST

U

SE

B

URN

I

N

The steps below will help to eliminate smoking from the heating elements’ protective coatings when

running above 150

°C. Perform the burn-in at the highest temperature the oven will be used at.

1.

Open the unit’s intake and exhaust vents. The oven’s exhaust should be positively vented

outside of the oven’s workspace during the Burn-In.

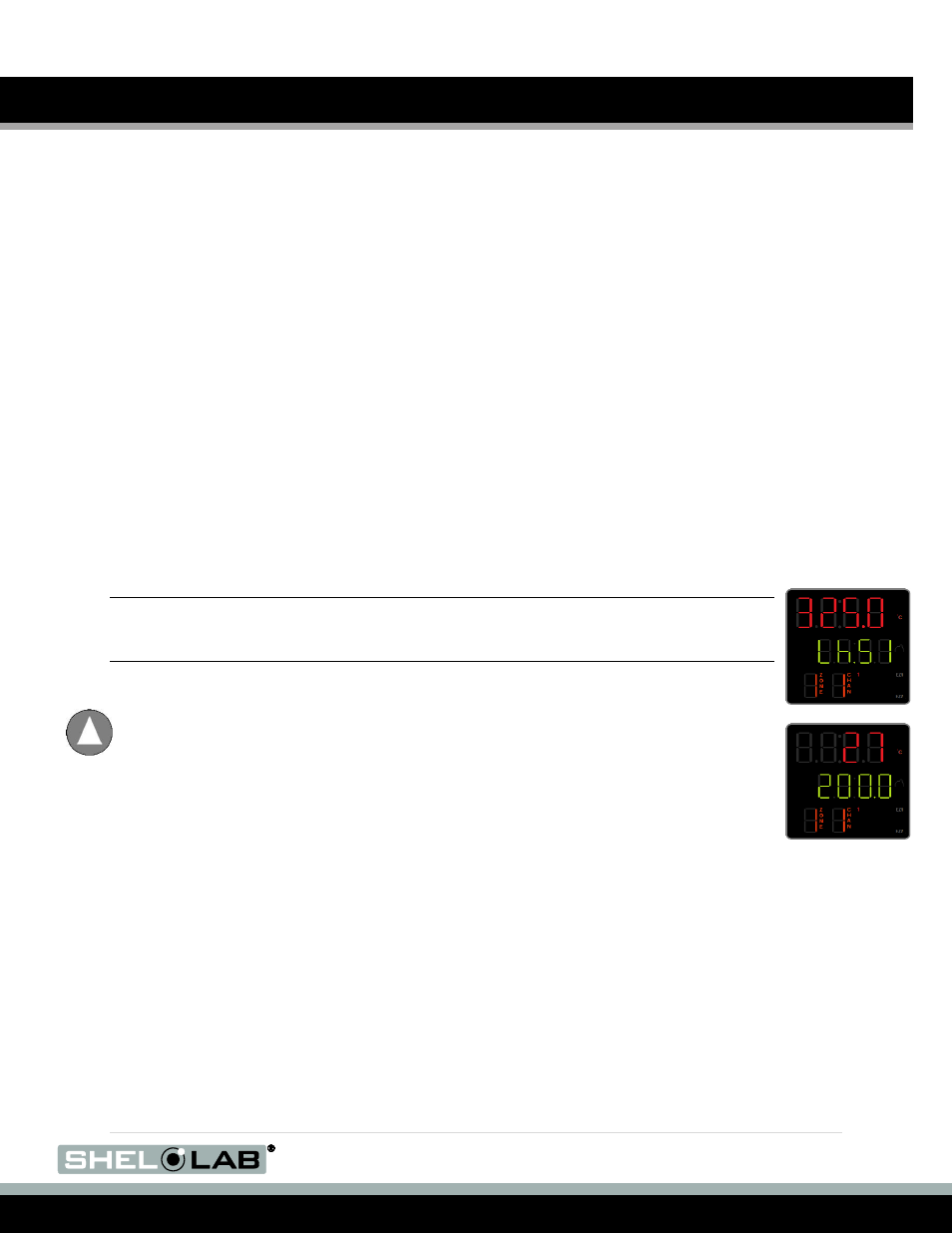

2. If you have not already done so, set the Over Temperature Limit to 325

°C, and the

temperature set point the highest operating temperature the oven will be used at.

3. Run the oven for a minimum of one (1) hour, until smoke from the heating elements

dissipates.

C

ALIBRATING THE

U

NIT

The oven should be calibrated at the temperature set point it will be run at. For heating profiles, the

oven should be calibrated to the average temperature of the profile.

1. Close the exhaust vent if your application or process calls for the exhaust vent to be

closed. Otherwise leave the vent open. The intake vent should always be open.

2. Place the temperature sensor of a certified reference device inside the oven, secured to the

center of the center-most shelf.

Note: Always use an independently certified temperature reference device that is regularly

calibrated to 0.5°C accuracy or better to conduct temperature calibrations or verifications.

. For best results, using a remote sensing reference device.

3. If you have not already done so, enter an Over Temperature Limit of 325

°C to

safeguard against the OTL System interfering with the calibration procedure.

4. If you have not already done so, enter the temperature set point you will use during

your application or process.

5. Allow the chamber to heat to up the set point, and then stabilize with no change in

temperature for at least a-half hour (30 minutes) prior to performing a temperature

calibration. This is to ensure the best possible temperature uniformity and accuracy in

the oven chamber.

6. Read the reference te

mperature device’s display. Compare its reading with the red

temperature shown in the Watlow Controller’s Temperature Display.

7.

If the reference device’s and the Watlow’s temperature readings are the same or fall within

the range of your laboratory or manufacturing protocol, the oven is now calibrated.

8. If there is a temperature difference between reference device and the Watlow, and that

difference falls outside your laboratory or manufacturing protocol

’s acceptable range, adjust

the Watlow to match the ref

erence device’s reading by entering a temperature offset. See

the next step.

Procedure Continued on Next Page