Installation, 5 installation – SeaLand 9400 Series RushFlush Installation User Manual

Page 7

7

SeaLand 9300-9400 Series RushFlush Toilets

Installation

5 Installation

5.1

General guidelines

For optimum toilet system preformance, follow these guidelines . Make sure to also follow any

governing codes or standards that apply to your installation .

Fresh Water Supply System Plumbing (fig .

2

, page 2)

DO NOT USE RAW WATER SUPPLY

1 . All water supply system plumbing should be 1 in . ID, with working pressure ratings above the

maximum water pump pressure . (100 PSI minimum recommended) .

2 . Water inlet strainer: 1 in . ID, 40 mesh

3 . Pressure gauge: 0-100 PSI

4 . Water pump: Grundfos

®

MQ3-35 or equivalent is recommended .

• 1 in . NPT connections

• Internal pressure switch: 50 PSI cut-out, 30 PSI cut-in

• Pump current draw is 8 amps @ 110V, 4 amps @ 220V, other pump manufacturers may vary .

• 15 GPM needed; pump actually rated at 22 GPM max . flow with no restrictions

• Depending on pump installation parameters, a pump of adequate suction lift capability

should be considered . The MQ3 pump has 25 feet of suction lift capability, but it varies

depending on horizontal suction run .

5 . Potable water pressure (accumulator) tank: AMTROL

®

Well-X-Trol

®

WX-105-PS or equivalent

is recommended .

• 3/4 in . NPT, or larger, connection

• 5 gallon total volume, 1 .8 gallon drawdown @ 30/50 PSI

• Air pressure charge should be set to 2-4 PSI below pump cut-in pressure .

• One 5-gal . accumulator tank recommended for up to 6 heads .

6 . Pressure relief valve:

• Installation recommended by accumulator tank manufacturer

• Should be installed near accumulator tank and pump, and set to open at excessive water

system pressures . This protects fresh water system in case of pressure switch malfunction .

7 . Check valve: will isolate the toilet system from the rest of the onboard freshwater system;

spring check, 1 in .

8 . Rim wash valve inside toilet:

• 1/2 in . NPT connection

• This water supply line can intersect from main 1 in . distribution line prior to high-flow water

jet valve using 1/2 in . plumbing to toilet .

9 .

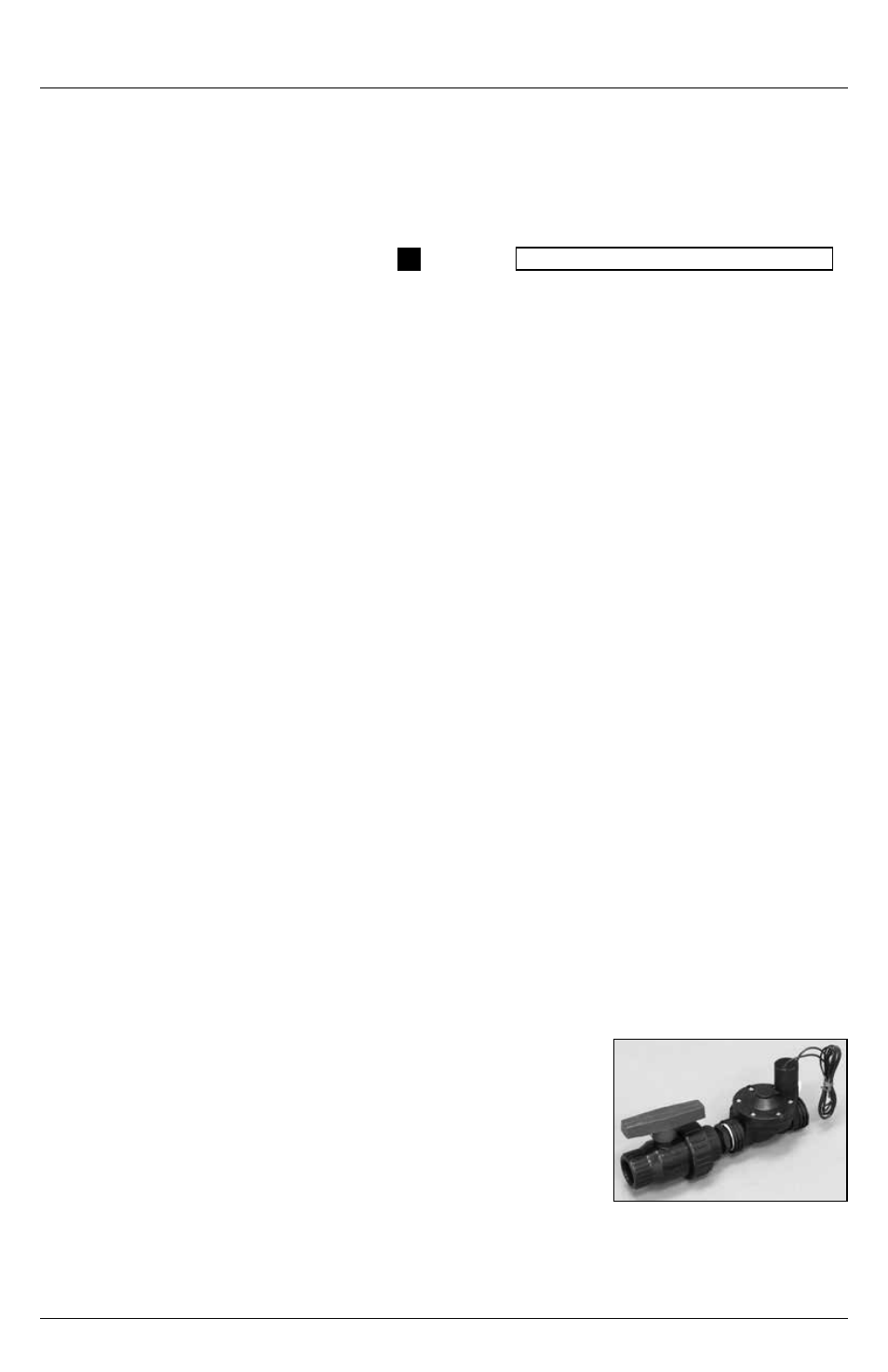

Electric high-flow water jet valve and maintenance ball valve, supplied with every toilet:

• 1 in . NPT connections

• Water jet valve should be closest to toilet . Maintenance ball

valve should be farthest from toilet – refer to direction arrow on

top of water jet valve inlet port .

• An in-line strainer is installed into the water jet valve inlet at the

factory . The cone shape protrudes out and against the direc-

tion of water flow away from the center of the valve, pointing

towards the maintenance ball valve .

• The water jet valve features a small white manual override lever

located next to the solenoid . This must be vertical for correct electrical operation . However,

it can be turned to the horizontal position to manually test the water system . Be sure to

return it back to vertical when testing is finished .

Electric water

jet valve