Removing the pressure gauge u-tube manometer, Completing the conversion, Figure 2. two-stage white rodgers gas valve – Reznor R6GN Option - Installation - LP Conv Kit User Manual

Page 5

5

NOTE 2: The unit firing rate should be inspected for each

installation as described in these instructions. The manifold

pressure may be different than the factory setting. If the

determination of the actual unit firing rate cannot be made with

quality instruments, then the manifold pressure should be set to

the factory setting shown on the unit rating label for installations

between 0 & 2,000 ft.

White Rodgers Gas valve Adjustment

(12 1/2 - 15 Ton Units):

1. Remove the protective cap from the top of the High fire gas

valve regulator as shown in the manufacturers instructions.

2. Set the manifold pressure to the factory settings, as shown

on the unit rating label – or to the correct manifold pressure

setting to obtain the correct firing rate.

NOTE: Turn the adjusting screw clockwise to increase pressure

or counterclockwise to reduce pressure. To prevent the screw

from backing all the way out from the valve, turn the screw slowly.

3. Replace the protective cap over the adjustment screws and

tighten.

NOTE: The unit Low firing rate (Stage 1 only) should be approx.

65% of the unit High firing rate. (Stage 1 & 2) See Table 2.

From example 1 (page 3): The furnace high fire rating of 129,000

Btuh reduced for 4,000 ft. elevation, would have a low fire rating

of 84,000 Btuh, or 0.65 x 129,000 Btuh.

4. Inspect the unit low firing rate in the same manner described

in the instructions for Verifying & Adjusting Firing Rate section

(Page 4).

5. Use the same procedure for the High fire adjustment described

in steps 1-3 above to adjust the Low fire manifold pressure. If

the firing rate cannot be determined, set the low fire manifold

pressure to the factory setting as shown on the unit rating

label, or refer to table 4.

REMOVING THE PREssURE GAUGE

u-TuBe mANOmeTeR

After the manifold pressure has been properly adjusted, the

pressure gauge or U-tube manometer must be removed from

the gas valve.

1. Turn the thermostat to its lowest setting.

2. Shut OFF the main gas supply to the unit at the manual shut-

off valve, located outside of the unit.

3. Shut OFF all electrical supplies to the unit.

4. Remove the manometer adapter from the gas valve and

replace it with the 1/8” NPT manifold pressure plug removed

earlier. Verify the plug is sealed tightly and not cross threaded.

5. Turn ON all electrical power to the unit.

6. Turn ON the main gas supply to the unit at the manual shut-

off valve, located outside of the unit.

COMPLETING THE CONVERsION

1. For all (*)R4(M,N) or R6GN-150 / 180 conversions to LP gas,

affix the conversion warning label (#703935) provided in the

kit to the outside of the units louvered burner access panel.

Next, affix the conversion information label (#710005) over

the Natural Gas warning label. Each label shall be prominent

and visible after installation.

2. Affix the gas valve manufactures labels to the valve as

described in the manufactures instructions.

3. Replace the unit’s louvered burner access panel.

4. Run the appliance through a complete cycle to assure proper

operation.

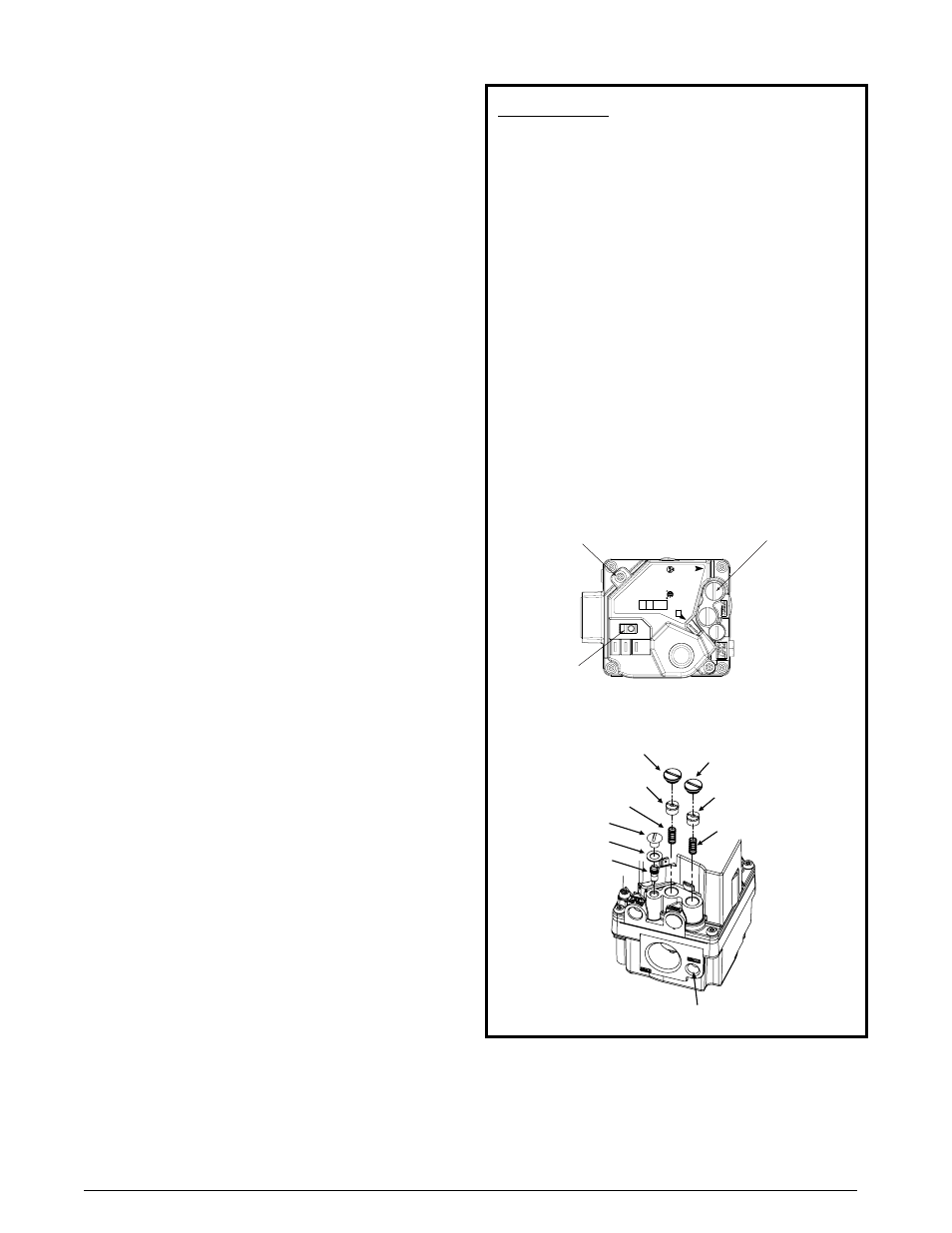

Figure 2. Two-Stage White Rodgers Gas valve

LOW REGULATOR COVER SCREW

(TWO STAGE ONLY)

REGULATOR ADJUST SCREW

REGULATOR SPRING

PILOT COVER SCREW

PILOT GASKET

PILOT ADJUST SCREW

REGULATOR SPRING

REGULATOR ADJUST SCREW

SINGLE STAGE AND TWO STAGE

HIGH REGULATOR COVER SCREW

MANIFOLD PRESSURE

TAP (OUTLET)

P/N - 624695

Model 36H64

IMPORTANT NOTE: When converting to LP/

Propane gas from natural gas, both springs from

the gas valve must be replaced by the white springs

included in the kit. The LP Propane springs for hIGh

and LOW fire are the same size, shape, and color.

1. Remove both regulator cover screws. See Figure 3.

2. Remove both regulator adjustment screws from the gas

valve (located beneath the cover screws).

3. Remove both Natural Gas regulator springs (color coded

silver / Plain) from the regulator sleeves.

4. Install both L.P. regulator springs (provided in the

conversion kit and color coded white) into the regulator

sleeves.

5. Replace the HIGH regulator adjustment screw and adjust

approximately 12 turns to the bottom stop.

6. Relace the LOW regulator adjustment screw and adjust

approximately 8 turns.

7. Check and adjust both regulator settings (High and Low

fire) to the firing rates listed in Table 3 for factory settings

below 2,000 ft elevation or for reduced firing rates based

on final high altitude calculations

Inlet

Pressure

Tap

Model 36H64

Manifold

Pressure

Tap (Outlet)

ON/OFF

Switch