Installing the heater, Direct mount, Optional mounting plate – Proheat A4 User Manual

Page 14

PROHEAT AIR A2/A4 INSTALLATION MANUAL

2-4

INSTALLING THE HEATER

Direct Mount

1.

Move or remove any hardware to gain access to mounting location.

2.

Using the appropriate mounting template (supplied at rear of installation

manual) mark the location of the mounting, exhaust, air intake and fuel holes.

3.

Using a drill bit and hole saw, drill 6 holes in the floor paying particular

attention to the underside of the vehicle.

4.

File down any sharp edges and test fit the heater. Trim any excess as

required to ensure the heater fits without binding and the heater gasket

sits flat on the floor to create a tight seal.

5.

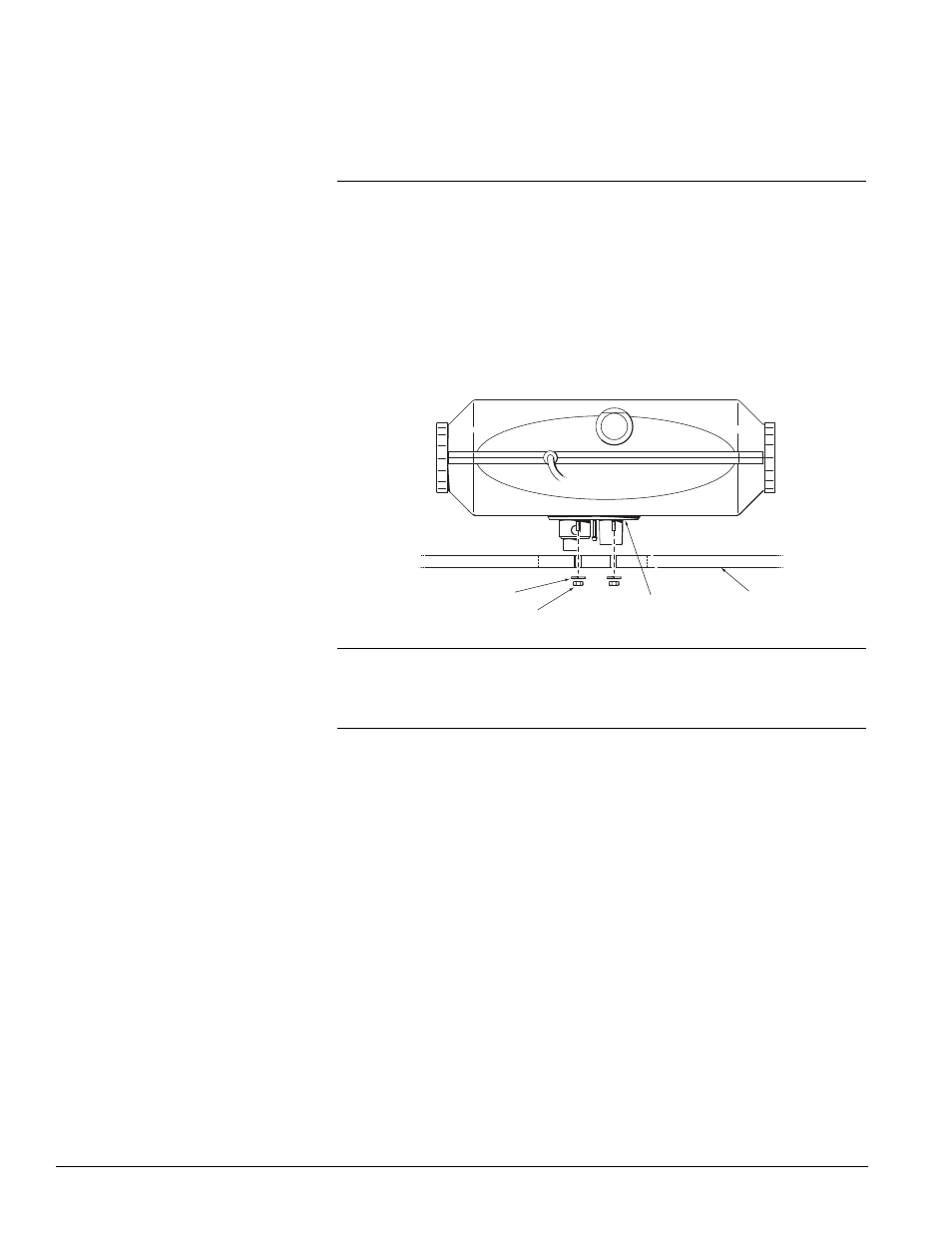

Install the heater and secure with the supplied hardware (refer to figure 6).

2.4.1

2.4.2

2.4

Optional Mounting Plate

This option is recommended for applications where direct mounting of the

heater is not possible such as:

NUT (4)

SILICON GASKET

FLANGE

SPRING WASHER (4)

CAB FLOOR

Figure 6. Heater Mounted Directly to Cab Floor.

• Uneven floors

• Composite or other heat sensitive

flooring material

• Extra thick flooring material

• Additional insulation under

the vehicle

1.

Move or remove any hardware to gain access to mounting location.

2.

Using the mounting plate as a guide, mark the location of the areas to

be drilled.

3.

Using a 3” hole saw for A2 or a 3.5” hole saw for A4, cut a hole in the

floor paying particular attention to the underside of the vehicle to ensure

you are not cutting through anything but the floor.

4.

Drill four holes for the plate mounting hardware if not using self tapping screws.

5.

Secure the heater to the mounting plate using the supplied hardware

(refer to figure 7).

6.

File down any sharp edges and test fit the heater. Trim any excess

material as required to ensure the heater fits without binding and the

mounting plate gasket creates a tight seal.

7.

Apply sealant to any exposed metal edges to prevent corrosion.

8.

Fasten the mounting plate to the floor using #12 self tapping screws x

1.5" (40 mm) (minimum) or 1/4" (6 mm) machine screw and nut.