Preventing store, Best practices, Stk22c48 – Cypress STK22C48 User Manual

Page 5

STK22C48

Document Number: 001-51000 Rev. **

Page 5 of 14

Preventing Store

The STORE

function is disabled by holding HSB high with a

driver capable of sourcing 30 mA at a V

OH

of at least 2.2V,

because it must overpower the internal pull down device. This

device drives HSB LOW for 20 ns at the onset of a STORE.

When the STK22C48 is connected for AutoStore operation

(system V

CC

connected to V

CC

and a 68

μF capacitor on V

CAP

)

and V

CC

crosses V

SWITCH

on the way down, the STK22C48

attempts to pull HSB LOW. If HSB does not actually get below

V

IL

, the part stops trying to pull HSB LOW and abort the STORE

attempt.

Best Practices

nvSRAM products have been used effectively for over 15 years.

While ease of use is one of the product’s main system values,

experience gained working with hundreds of applications has

resulted in the following suggestions as best practices:

■

The nonvolatile cells in an nvSRAM are programmed on the

test floor during final test and quality assurance. Incoming

inspection routines at customer or contract manufacturer’s

sites sometimes reprogram these values. Final NV patterns are

typically repeating patterns of AA, 55, 00, FF, A5, or 5A. The

end product’s firmware should not assume that an NV array is

in a set programmed state. Routines that check memory

content values to determine first time system configuration,

cold or warm boot status, and so on must always program a

unique NV pattern (for example, complex 4-byte pattern of 46

E6 49 53 hex or more random bytes) as part of the final system

manufacturing test to ensure these system routines work

consistently.

■

Power up boot firmware routines should rewrite the nvSRAM

into the desired state. While the nvSRAM is shipped in a preset

state, best practice is to again rewrite the nvSRAM into the

desired state as a safeguard against events that might flip the

bit inadvertently (program bugs, incoming inspection routines,

and so on).

■

The V

CAP

value specified in this data sheet includes a minimum

and a maximum value size. The best practice is to meet this

requirement and not exceed the maximum V

CAP

value because

the higher inrush currents may reduce the reliability of the

internal pass transistor. Customers who want to use a larger

V

CAP

value to make sure there is extra store charge should

discuss their V

CAP

size selection with Cypress.

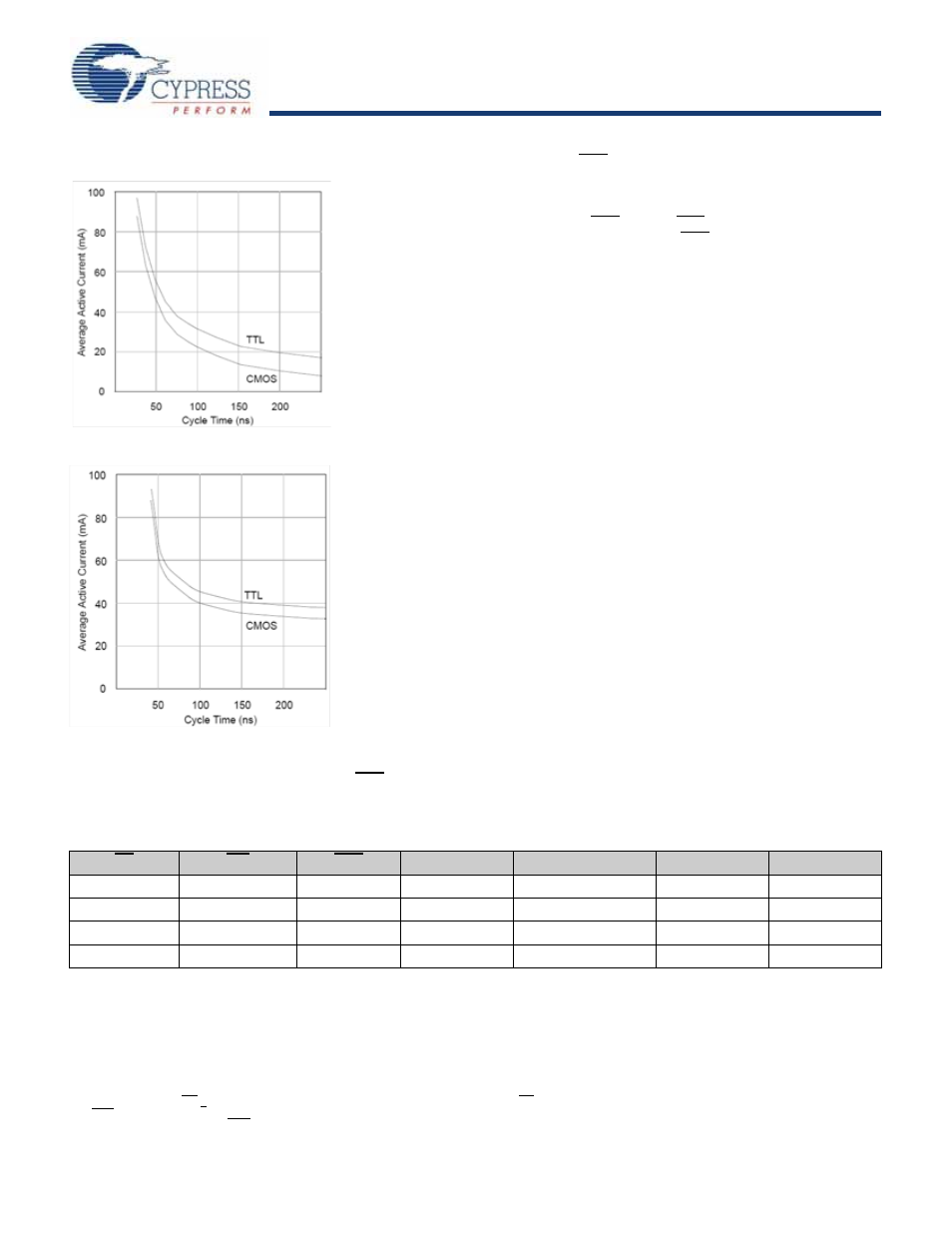

Figure 4. Current Versus Cycle Time (Read)

Figure 5. Current Versus Cycle Time (Write)

Table 2. Hardware Mode Selection

CE

WE

HSB

A10–A0

Mode

IO

Power

H

X

H

X

Not Selected

Output High Z

Standby

L

H

H

X

Read SRAM

Output Data

Active

[1]

L

L

H

X

Write SRAM

Input Data

Active

X

X

L

X

Nonvolatile STORE

Output High Z

I

CC2

Notes

1. I/O state assumes OE < V

IL

. Activation of nonvolatile cycles does not depend on state of OE.

2. HSB STORE operation occurs only if an SRAM Write is done since the last nonvolatile cycle. After the STORE (If any) completes, the part goes into standby mode,

inhibiting all operations until HSB rises.