Novak Super Rooster / Rooster ESC(1850) User Manual

Operating instructions, Rooster/super rooster, Step 1

ROOSTER/SUPER ROOSTER

The ROOSTER is the long standing benchmark in reliable

reversible speed controls for 6-7cell/mild-modified set-ups.

The SUPER ROOSTER is stronger and faster than the

original. Equipped with a Heavy-Duty BEC for today’s

high power servos, twelve of the toughest HYPERFET III

TM

transistors, and extra-long 14G power and signal harness

wires, the Super Rooster handles big trucks, wild motors,

and even dual motor set-ups.

Both speed controls feature the original One-Touch Set-Up

(There’s nothing easier!)

and exclusive Polar Drive

Technology

TM

for the smoothest throttle response and

improved radio system performance. Reverse Disable

Circuitry

TM

locks-out reverse for racing use, while Smart

Braking Circuitry

TM

brings the model to a slow speed

before hitting reverse to save your vehicle’s gearbox and

reduce speed control heating.

Other features include brake light circuitry to power two

high-intensity LEDs available separetly in the Novak Brake

Light LED Kit (Accessory #5655) for enhanced realism,

Radio Priority Circuitry

TM

to maintain steering control

even after the battery has discharged, dual-level thermal

protection, and the Novak Input Plug System

TM

.

SPECIFICATIONS

Input Voltage

(1.2VDC/cell)

6-7 cells

6-10 cells

Case Width

1.63 inches

1.63 inches

Case Depth

2.02 inches

2.02 inches

Case Height

(w/h.sinks)

1.22 inches

1.22 inches

Weight

(w/heat sinks)

3.00 ounces

4.00 ounces

On-Resist.–Fwd.

(@Trans)

0.018

Ω

0.002

Ω

On-Resist.–Rev.

(@Trans)

0.018

Ω

0.004

Ω

Rated Current–Fwd.

100 amps

320 amps

Rated Current–Rev.

100 amps

160 amps

Braking Current

100 amps

160 amps

Rev. Delay

(after Smart Braking)

Zero Sec.

Zero Sec.

BEC Voltage

5.7 volts DC 6.0 volts DC

BEC Current

0.5 amps

3.0 amps

Power Wire

16G / 6”

14G / 14”

Signal Harness

26G / 6”

26G / 15”

Transistor Type

MEGAFET

HYPERFET III

PWM Frequency

1250 Hertz

1250 Hertz

Motor Limit

Mild

Modified No Limit

Part Number

1850

1860

DETAILED INFORMATION

Included with the speed control is the Novak Input Plug

System

TM

to convert the Futaba J style signal harness for

compatibility with Airtronics, KO, Kyosho, JR, Airtronics Z,

and Hitec radios. Refer to Figures 1 through 3 to convert plug.

Airtronics (A) KO Kyosho (KYO) JR/Hitec/AirZ

FIGURE 1 With a small standard screwdriver, press on

each of the three metal prongs until the wires are easy to

remove. Remove wires.

FIGURE 2 With the screwdriver, carefully lift each of the

metal locking tabs to the angle shown.

FIGURE 3 Insert each pin into the correct plug slot. Each

pin should "click" into place.

(Airtronics plug shown)

WHT = White wire terminal (signal)

BLK = Black wire terminal (negative)

RED = Red wire terminal (positive)

CAUTION Improper installation of these wires may cause

damage to the receiver, servo, and speed control.

STEP 1

CHANGING THE INPUT PLUG

The locking tab must not extend

outside the plastic plug housing.

PRECAUTIONS

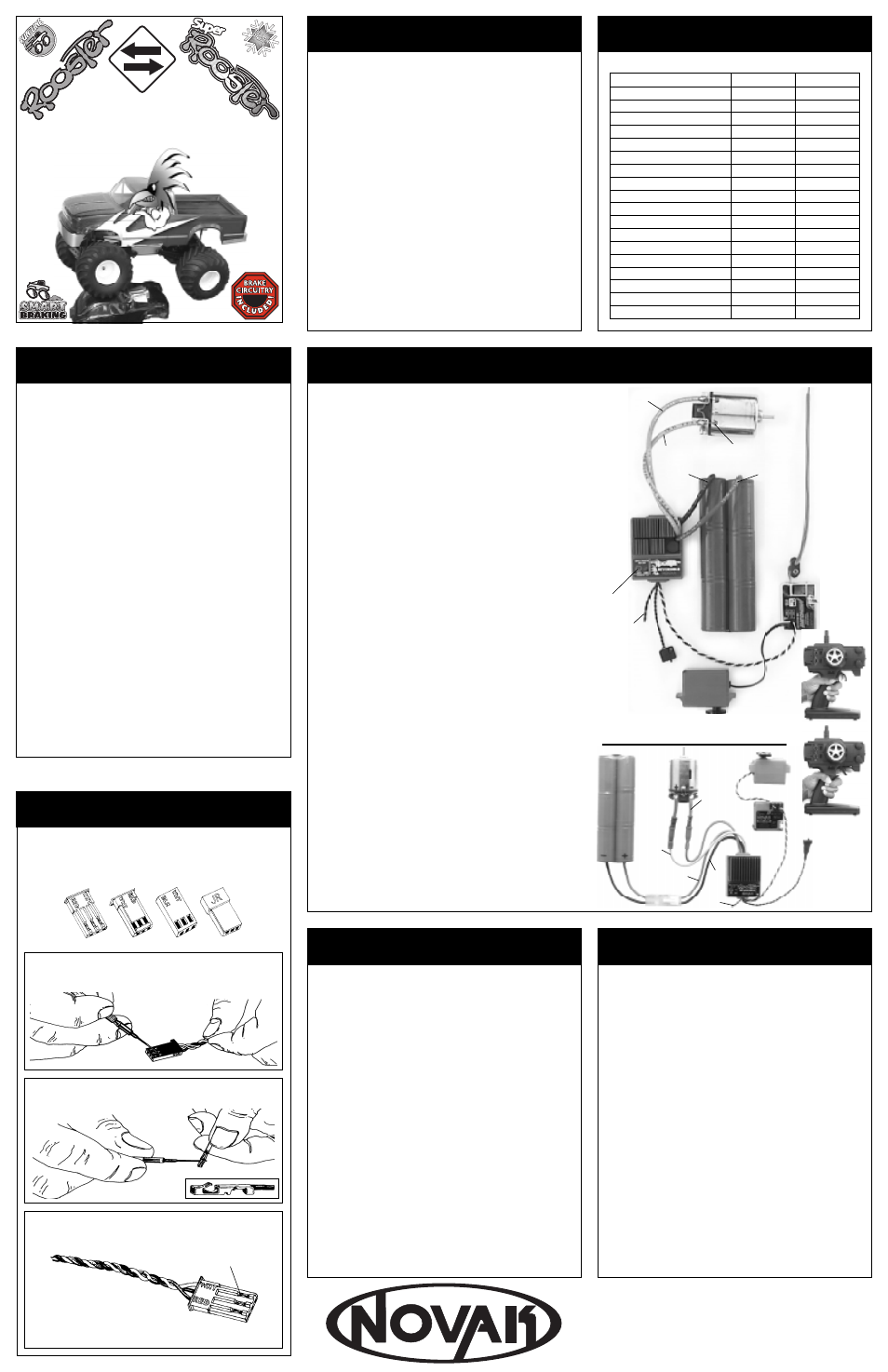

QUICK SET-UP

(SUPER ROOSTER SHOWN)

FOR DETAILED INFO. REFER TO STEPS 1 THRU 7

A.

INSTALL SPEED CONTROL

Use double-sided tape to mount ESC in model where the

power wires are neatly routed away from the receiver and

antenna. For more details refer to Step 2.

B.

CONNECT SPEED CONTROL TO RECEIVER

Plug the ESC input signal harness into the throttle channel

of receiver. Make sure the proper plug plastic is installed

on ESC signal harness. Refer to Step 1 for changing plug.

C.

CONNECT SPEED CONTROL TO BATTERY

ROOSTER––Plug the JST/Tamiya connector from speed

control into a 6 or 7 cell battery pack (1.2 volts DC/cell).

SUPER ROOSTER––Solder the BLACK wire of speed control

to the negative side of a completely charged 6 to 10 cell

battery pack (1.2 volts DC/cell).

Solder the RED wire of speed control to battery positive.

D.

TURN ON TRANSMITTER POWER

Refer to Step 5 for transmitter adjustments.

E.

TURN ON SPEED CONTROL

Slide ON/OFF switch to ON position.

F.

PRESS AND HOLD SPEED CONTROL SET BUTTON

With transmitter throttle in neutral position, press and hold

SET button until status LED turns solid red, then release.

G.

PULL THROTTLE TO FULL-FORWARD POSITION

Hold until status LED turns solid green.

H.

PUSH THROTTLE TO FULL-REVERSE POSITION

Hold until status LED blinks green, then return throttle to

neutral position. LED will then turn solid red indicating

proper programming and throttle is in neutral position.

I.

CONNECT SPEED CONTROL TO MOTOR

Turn off speed control then transmitter.

ROOSTER––Plug the bullet connector on the YELLOW wire

of speed control to motor positive.

Plug the bullet connector on the BLUE wire of speed control

to motor negative.

SUPER ROOSTER––Solder the BLUE wire of speed control

to motor negative.

Solder the YELLOW wire of speed control to motor positive.

J.

KICK-UP A ROOST!

Turn on transmitter and then speed control.

Please refer to Step 7 for instructions on disabling the

reverse portion of the speed control for use when racing.

black wire

(-) (+) red wire

blue

wire

•

WATER & ELECTRONICS DON’T MIX!

Do not

operate model in or around water. Never allow water,

moisture, or other foreign materials to get inside the ESC.

• ROOSTER–6 or 7 CELLS ONLY Never use fewer than 6 or

more than 7 cells (7.2-8.4 volts DC) in main battery pack.

• SUPER ROOSTER–6 to 10 CELLS ONLY Never use fewer

than 6 or more than 10 cells

(7.2-12.0 VDC)

in battery pack.

• MOTOR CAPACITORS REQUIRED Three 0.1

µ

F (50V)

ceramic capacitors (included) must be properly installed

on every motor to prevent radio interference. Additional

capacitors are available in Novak kit #5620.

• ALWAYS USE HEAT SINKS Four heat sinks are included to

properly fit the Super Rooster and they must be used for

maximum cooling and performance. Replacement Super

Rooster heat sinks are available in Novak kit #5409.

• NO REVERSE VOLTAGE! Reverse battery polarity can

damage speed control––Disconnect battery immediately.

• NO SCHOTTKY DIODES External Schottky diodes must

NOT be used with the reversible speed controls. Using an

external Schottky diode will damage the ESC.

• DON’T LET TRANSISTOR TABS TOUCH Never allow

separate transistor banks to touch each other or any exposed

metal. This will create a short circuit and damage the ESC.

• DISCONNECT THE BATTERIES Always disconnect the

battery pack from the speed control when not in use.

• TRANSMITTER ON FIRST Always turn on the power of

your transmitter first so that you will have control of the

radio equipment when you turn on the speed control.

• DON’T GET BURNT

! Transistor tabs and the heat sinks

can get extremely hot, so be careful not to touch them

until they cool. Supply adequate air flow for cooling.

• INSULATE WIRES Always insulate exposed wiring with

heat shrink tubing to prevent short circuits.

NOVAK ELECTRONICS, INC.

18910 Teller Avenue

Irvine, CA 92612

www.teamnovak.com

yellow

wire

Heat sinks are required with the Rooster & Super Rooster

for optimum performance and power handling. The

Rooster heat sink comes factory installed and must not

be removed. Included with the Super Rooster are heat

sinks to fit onto the ESC’s three separate transistor tab banks.

To Install Super Rooster Heat Sinks:

1. INSTALL THE HEAT SINKS Place ESC on a flat surface

and press the long/5-transistor heat sink onto the bank

of 4 transistors on the upper left. Next, press the long/

3-transistor heat sink onto the bank of 2 transistors on

the upper right. The 2 remaining short/3-transistor heat

sinks go onto the bottom bank of 6 transistors.

The heat sinks should press onto the transistors with a

snug fit. If they are installed upside-down (longer fins

up)

or shifted off to one side, they will be too loose.

NOTE: Do not use too much force when installing the heat sinks

because you can damage the transistors or other components

on the PC board. Never use a vise or pliers to install the heat sinks.

2. DO NOT USE GLUE Do not use glue or adhesives to

attach the heat sinks to the transistors.

3. DO NOT SHORT CIRCUIT HEAT SINKS The three

banks of transistor tabs are separated by plastic on the

case top. Each bank of heat sinks should never contact

each other or other conductive objects (metal, etc.),

or they will short circuit and damage the speed control.

STEP 2

MOUNTING INSTRUCTIONS

1. DETERMINE BEST ESC MOUNTING LOCATION

The ESC should be positioned away from the receiver

and antenna as shown in the Quick Set-Up photo

above. Choose a mounting position that will keep the

power wires as short as possible without obstructing

movement of the suspension or the motor pod.

Remember, cooler operating temperatures mean higher

efficiency. So, choose a mounting position that allows

maximum airflow through the heat sinks.

2. INSTALL SPEED CONTROL

Use the included double-sided tape to mount the ESC.

3. INSTALL ON/OFF SWITCH

Determine a convenient place to mount the switch

where it will be easy to get to. Mount the switch using

a piece of double-sided tape or with a screw through

the hole in the base of the switch housing.

4. INSTALL RECEIVER

Mount the receiver as far from the motor, power wires,

battery, and servo as possible. These components all

emit radio noise when the throttle is being applied.

On graphite or aluminum, place the receiver on edge

with the crystal and antenna as far above the chassis

as possible. Mount the antenna close to the receiver

and trail any excess wire off the top of the antenna.

STEP 3

SUPER ROOSTER HEAT SINK INSTALLATION

twist

motor

wires to

reduce RF

noise

brake

light wires

trail excess

wire off top of

antenna mast

three 0.1

µ

F capacitors

•NO SCHOTTKY•

(+)

(-)

Part #1860

Part #1850

SPECIFICATION

ROOSTER

SUPER ROOSTER

OPERATING

INSTRUCTIONS

I.

C.

F.

B.

E.

G.

H.

I.

C.

**ROOSTER (Plug Connections)

blue

wire

yellow

wire

black

wire

red

wire

brake

wires

RACING ELECTRONICS

RACING ELECTRONICS