Step, Connect input harness, Motor installation – Novak HV Motor Wiring & Gear Selection (55-3020-1) User Manual

Page 2: Battery connection, Mounting esc, Figure 4: set-up photo, Sensor harness wiring

The HV-Maxx ESC has the industry-standard receiver input connector on a

user-replaceable input harness & works with all major radio brand’s new

receivers. However, some very old receivers must have the wiring sequence

in the plastic 3-pin connector housing changed. This is important, because

receiver & servo electronics may be damaged if the sequence is incorrect.

JR • Hitec • Futaba • New KO • Airtronics Z

JR • Hitec • Futaba • New KO • Airtronics Z

JR, Hitec, Futaba, new KO, & Airtronics Z receivers do not need input

harness re-wiring. Airtronics Z receivers have blue plastic cases & new KO

cases have tabs on the input harness openings as in Figure 1.

• Plug the connector on one end of the input harness into the receiver with

the BLACK wire toward the outside edge of receiver case.

• Plug the other end of the input harness into 3-pin header inside rectangular

opening on top of the HV-Maxx ESC’s case with the WHITE wire toward

the ‘S’ (signal) marking on the ESC’s label.

Old-style KO • Old-style Sanwa/Airtronics

Old-style KO • Old-style Sanwa/Airtronics

If you have an older KO or Sanwa/Airtronics, you must change the

sequence of the ESC’s input harness wires--Old Sanwa/Airtronics cases

are black color & Old KO cases do not have tab openings, as in Figure 2 above.

• Using a small flat blade screwdriver, remove the red & black wires from the

plastic housing at the receiver end of the input harness as in Figure 3 below.

• Interchange the red and black wires in the plastic 3-pin connector housing

at the receiver end of the input harness.

• Insert modified end of the harness into the receiver with the RED wire

toward the outside edge of receiver case.

FIGURE 3

With a small standard screwdriver, gently lift plastic

prong until wire and metal socket easily slide out of plastic housing.

changing wiring sequence

changing wiring sequence

changing wiring sequence

changing wiring sequence

changing wiring sequence

@

@

@

@

@

receiver end

receiver end

receiver end

receiver end

receiver end

FIGURE 1

FIGURE 2

New KO (with tabs)

Old KO (no tabs)

tabs

no tabs

black

red

red

white

black

white

P2

P3

step

step

step

step

step

1

11

1

1

–

connect input harness

step

step

step

step

step

3

3

3

3

3

–

motor installation

1. MOTOR CAPACITORS NOT NEEDED

Novak brushless motors have built-in motor capacitors and do not

require external ones on the motor

(see separate Motor Sheet for more info)

.

2. DO NOT USE SCHOTTKY DIODES

Schottky diodes must NOT be used with reversible speed controls

(including brushless). Using a Schottky diode will damage the speed

control and void the product’s warranty.

3. FACTORY-INSTALLED POWER CAPACITOR

MOUNTING THE POWER CAPACITOR:

Mount the Power Capacitor

to the vehicle’s chassis using the included double-sided tape or with

tie-wraps

[in Traxxas E-Maxx: You can tie-wrap the power capacitor to

the “X” in the middle of the rear shock tower].

If Power Cap. becomes dented or damaged, ESC failure can occur--replace

immediately. Longer Power Capacitor wires decrease performance.

4. CHECK MOTOR SCREW LENGTH

You must check the length of the motor screw to ensure that the motor

will not be damaged. You should have no more than 1/8” of screw

extending past the vehicle’s motor mounting plate (2-4mm). Too little

can strip the threads in the end bell, and any more will cause damage

& short-circuiting inside the motor & will void warranty.

[the included

M3x8mm screws are the proper length for the Traxxas E-Maxx]

5. INSTALL PINION GEAR

{

refer to ‘GEAR SELECTION’ portion of MOTOR

}

SET-UP sheet to determine the proper gearing

After selecting the proper final gear ratio, install pinion gear (usually

about 2 teeth smaller than stock) on motor and position set-screw over

the flat on the end of the motor shaft. Test fit motor in vehicle to align

pinion and spur gears, then tighten pinion gear on shaft.

6. USE SPIRAL WRAP TO BUNDLE/PROTECT SENSOR WIRES

Use the spiral wrap included in the HV-Maxx’s accessory kit to protect

the 6 Teflon sensor harness wires between the ESC & the motor. You

can also use the spiral wrap and tie-wraps to bundle the sensor harness

& motor power wires neatly together.

step

step

step

step

step

4

4

4

4

4

–

battery CONNECTION

The HV-Maxx is very powerful, and capable of very efficient delivery of

battery power to its brushless motor. Therefore, good connections must

be made between the battery, speed control, and motor.

A common cause of perfomance problems and ESC failures is poor

connections--If you have any doubts about your soldering skill, we suggest

installing the system without modifying the length of the power wires,

or seeking assistance at your hobby shop or track.

Once you’ve mounted the HV-Maxx ESC & motor, it’s time for the bat-

tery connections. The HV-Maxx ESC is factory-wired for two battery

packs, and is equipped with high-power versions of JST/Tamiya-style

battery connectors so you can use standard sport battery packs.

Using different style connectors is discussed on the Motor Sheet.

BATTERY PACK CONNECTIONS

The HV-Maxx system is designed to be used with two battery packs.

However, it can also be used with one standard R/C battery pack (6 or 7

cells @ 1.2VDC/cell) or with one 12 volt DC battery. Using the HV-Maxx

with a single battery requires special wiring and is discussed below.

using dual battery pack

using dual battery packs

s

::

a.

a.

a.

a.

a.

Connect one battery pack (6-7 cells @ 1.2VDC/cell) to the JST/Tamiya

connector at the end of the red & black wires coming from the

ESC’s BAT.1 solder tabs as marked on the HV-Maxx case labels.

b.

b.

b.

b.

b.

Connect a second battery pack to the JST/Tamiya connector coming

from the ESC’s BAT.2 solder tabs.

using single battery pac

using single battery pack

k

::

To use the HV-Maxx with a single 6-14 cell (1.2VDC/cell) pack or a

12VDC battery, the pack/battery must be connected to the BAT.2

input & the BAT.1 input must be shorted together

(see Fig.7 below/left)

.

a.

a.

a.

a.

a.

Cut the black wire coming from the BAT.1 (–) solder tab (battery

wire closest to the front of ESC) about 2-3” above the solder tab.

b.

b.

b.

b.

b.

Strip a 1/8-1/4” of insulation off the end of the BAT.1 (–) black

wire. Tightly twist the strands of wire & lightly tin with solder.

CAUTION: When making battery wire solder connections at the

HV-Maxx’s Direct-Solder Wiring Tabs, it is important to not overheat

& damage PCB (printed ciruit board) with the soldering iron by applying

prolonged or excessive heating (PCB damage voids warranty).

c.

c.

c.

c.

c.

Remove the red wire from the BAT.1 (+) solder tab:

Use a soldering iron to apply heat to the wire’s solder joint while

gently pulling on the wire to remove it from the PC Board’s hole.

d.

d.

d.

d.

d.

Solder the stripped & tinned end of the black wire coming from the

ESC’s BAT.1 (–) solder tab into the BAT.1 (+) solder tab:

Insert the wire end into the BAT.1 (+) solder tab hole (if there is still

solder in the hole you can melt it with the iron while pushing the wire

through the hole). Apply heat to the section of wire that is sticking

through the tab’s hole, and add solder to the tip of the soldering

iron and to the wire. Add just enough solder to form a clean &

continuous joint from the plated area of the solder tab up onto the

wire. Use side cutters to trim excess wire above tab (about 1/16”).

e.

e.

e.

e.

e.

Connect battery pack (6-14 cells @ 1.2VDC/cell) to the JST/Tamiya

connector at the end of the red & black wires coming from the

ESC’s BAT.2 solder tabs as marked on the HV-Maxx case labels.

B.E.C. OUTPUT WHEN USING SINGLE BATTERY ABOVE 8.4VDC

When using a single battery above 8.4VDC (like a lead acid or gell cell), there

is limited output from the B.E.C. circuit--using a separate receiver battery

pack (refer to Motor/Wiring Sheet) can improve servo/receiver performance.

Important motor, gear selection, & wiring information on separate Motor/Wiring Sheet

sensor harness wiring

sensor harness wiring

sensor harness wiring

sensor harness wiring

sensor harness wiring

Should any of the 26G Teflon wires pull out of the connector on the motor’s

sensor harness, re-insert them in the appropriate slot in the connector as

shown below. There is a small plastic tab that grabs a small raised barb on

the back of the metal socket crimped to the Teflon wire’s end. The plastic

tab should be checked to make sure it has not deformed excessively before

inserting the socket into the plastic connector housing.

If the sensor harness gets damaged, contact our Customer Service Department.

step

step

step

step

step

2

2

2

2

2

–

MOUNTiNG ESC

Mount ESC with power wires away from other electronics & moving parts.

Select a location that allows airflow through heat sinks--

If the ESC gets air

flow, it will run cooler; and that means it will be more efficient, and you will go faster!

For single battery pack use, proceed to STEP 4 before completing STEPs 2 & 3

1. MOUNT HV-MAXX ESC IN VEHICLE using the included double-sided

tape or with screws through the mounting ears on the sides of the case

[in Traxxas E-Maxx: If using cooling fan, install with the included #4x1”

self-tapping screws--If not using cooling fan, use the stock mounting

screws from the original ESC in the E-Maxx].

2. PLUG COOLING FAN INTO ESC’s FAN POWER OUTPUT JACK Remove

rubber plug from ESC’s fan power output jack located directly above the

input signal harness opening (see Fig.5 below/right) & pull it back out of the

way. Plug fan connector into the power output jack (Note polarity: RED =

+

).

3. INSTALL FAN BRACKET ONTO ESC using included #6x5/8” self-tapping

screws

[in Traxxas E-Maxx: The #4x1” self-tapping screws will be used & will

pass through the cooling fan bracket, then the ESC’s mounting ears, & into

the holes in the E-Maxx’s chassis]

. Position fan bracket on ESC so that the

holes for attaching the fan to the bracket are towards the front of ESC.

4. INSTALL COOLING FAN ONTO BRACKET using the included 4-40x1/2”

socket head screws. Position fan so it is directly over the ESC’s heat sinks

and thread screws into the 2 holes on the top of the fan mounting bracket.

5. INSTALL ESC ON/OFF SWITCH using a screw or double-sided tape where

it will be easy to access

[in Traxxas E-Maxx: You can screw the switch to

one of the holes from the original switch]

.

6. CONNECT ESC TO RECEIVER––Configure input harness wires as

described in Step 1 & connect ESC to the THROTTLE CHANNEL (#2) of

receiver. Be sure receiver & antenna are mounted as far from ESC, power

wires, battery, and servo as possible--these components all emit RF noise

when throttle is applied.

On graphite or aluminum chassis vehicles, it may help

to place receiver on edge with crystal & antenna as far above chassis as possible.

Note: Mount antenna as close to receiver as possible--trail any excess wire off top

of antenna mast (cutting or coiling excess antenna wire will reduce radio range).

Motor Installation: continued –>

why you want a power capacitor

why you want a power capacitor

why you want a power capacitor

why you want a power capacitor

why you want a power capacitor

The HV-Maxx comes with the best available Power Capacitor that drops ESC operating

temperatures by 10-15

°

F (remember, cooler means your ESC will be more efficient &

faster) and dissipates noise & voltage spikes from the ESC’s high switching speed.

You MUST use Novak Power Capacitors--other capacitors with similar ratings don’t provide

equal protection. We’ve done extensive research to find capacitors with the very best quality factors.

continued I

^

7. INSTALL MOTOR IN VEHICLE

For most applications, the HV-Maxx ESC & brushless motor can be

installed in the vehicle without any modification to the motor wiring.

• Determine the best routing for the motor’s sensor harness (6 small Teflon

wires).

[in Traxxas E-Maxx: Both the sensor harness & the ESC’s input

signal harness can be routed through the gap located beneath the

pinion/spur gear cover on the left side of the vehicle--between the

transmission case & the battery box wall].

• Attach motor to the vehicle’s motor mount with included M3 motor

screws (determine proper length motor screws in Step 3, #4), using one of

the three sets of threaded mounting holes in the front end bell--select

a mounting position that will avoid short-circuiting of motor’s solder tabs

against conductive surfaces like aluminum or graphite.

The HV motor included in the HV-Maxx brushless motor system comes

with a heat sink factory-installed on it for extra cooling under excessive

loads

[for the Traxxas E-Maxx: The heat sink is already pre-positioned

on the motor for installation on the left hand side of the E-Maxx--

install motor with the solder tabs toward the middle of the vehicle &

angled slightly upward].

You can rotate the heat sink on the motor as

needed for different applications--beware of any wires crossing the

sharp ends of the heat sink, as short-circuiting may occur.

• Check gear mesh for proper free play. You want to have a small amount

of play between the pinion & spur gears (about the thickness of a piece

of paper)--check free play at several positions around the spur gear.

• Tighten motor into position once desired gear mesh has been adjusted-

-avoid using excessive force when tightening motor screws, as the

threaded holes could become stripped.

• For vehicles that originally used 2 motors, use the included motor

hole cover in place of the 2nd motor (this will help keep debris out of

the slipper and the gears). Install motor hole cover using the vehicle’s

original motor screws or with two 4-40x1/4” screws.

• Replace any parts of the vehicle that were removed to install the motor.

[in Traxxas E-Maxx: Replace the pinion/spur gear cover]

.

• Determine best routing for the motor’s power wires. If your vehicle

requires unsoldering motor to route power wires through the

shock tower or chassis, refer to “REPLACING POWER WIRES AT ESC &

MOTOR” on Motor Sheet.

[in Traxxas E-Maxx: Route motor power wires

along the right side of transmission--2 wires press into the wire holds on

the lower side of pinion/spur gear cover, & the 3rd wire goes through

the gap between the transmission case & the battery box wall].

black

orange

white

plastic

tabs

red

blue

green

metal

barbs

raised

metal

barb

metal socket

on end of Teflon

sensor harness wires

FIGURE 5:

Cooling fan connection

fan plugs

into fan power

output jack

self-tapping screws

into ESC mounting

ears or through ears

into chassis

4-40x1/2” cap

screws secure

fan to custom

bracket

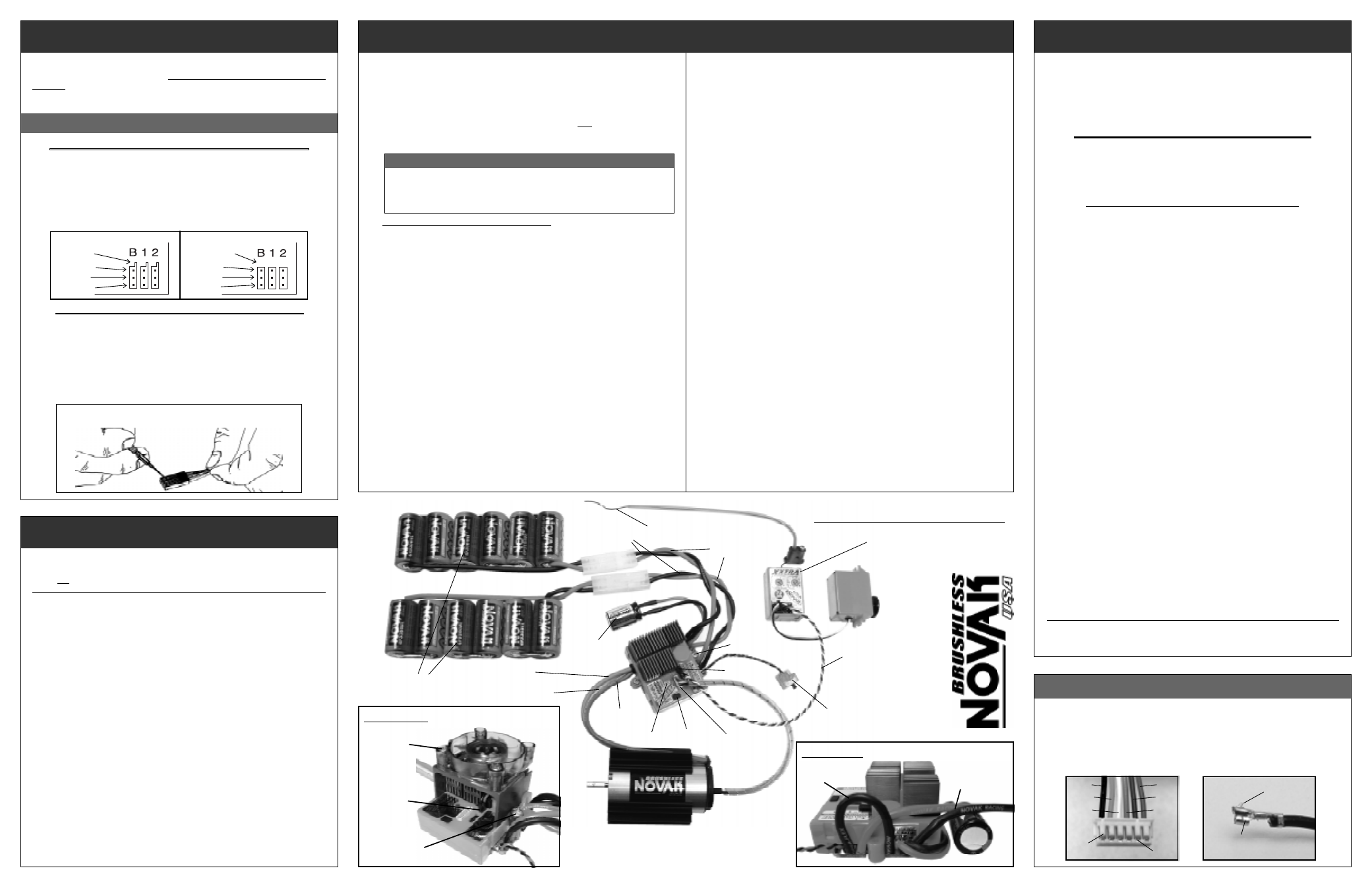

Power Cap

taped or

tie-wrapped

to chassis

One-Touch

button

Keep receiver & antenna as

far from motor, servo,

battery, & power wires as

possible.

U

ser-replaceable

input harness

Black power wires

(battery negative)

Trail excess wire off

top of antenna mast

Red power wires

(battery positive)

Blue power wire

(motor phase ‘A’)

(–)

(+)

6 to 7 cell battery packs

Novak Platinum GP3300VE

shown (part #6000)

ON/OFF switch

screwed or taped to chassis

(–)

(+)

Yellow power wire

(motor phase ‘B’)

servo

plugged

into

ch. (#1)

Orange power wire

(motor phase ‘C’)

Status LEDs

Sensor

harness

input

Fan power

output jack

ESC screw

mounting ears

FIGURE 4: SET-UP PHOTO

FIGURE 6:

BAT.1 shorting for single battery usage

battery connects

to BAT.2 input

BAT.1(–) shorted

to BAT.1(+)