Novak GTX Programmable Racing ESC 7th Profile Customizing Sheet (IM-1780-2) User Manual

Basic set-up guide -- gtx, Specifications, Step

#IM-1780-2

9-2004

SPECIFICATIONS

Input Voltage ...........................................4-7 cells

(1.2 volts DC/cell)

Motor Limit ..................................... Any brushed-type R/C motor

Case Size.............................. 1.11”x0.86”x0.60”

[28.2x21.8x15.2mm]

Weight

(w/o wires)

.........................................0.64 ounce

[18 grams]

On-Resistance

@ Transistors**

......................................... 0.00034 Ω

Rated Current

(forward/braking)

.................................. 150/60 amps

B.E.C. Voltage/Current ............................... 6.0 volts DC/3.0 amps

Schottky Diode ................................................... 36 amps

(built-in)

Power Wire ............................................................ 10 inches/14G

Signal Harness

(replaceable)

...................................9 inches

[22.8 cm]

Throttle Programs ..........................................7

(6 fixed/1 adjustable)

Minimum Brake

(all Programs)

........................................... 0%-50%

PWM Frequency ............................................................. 1-11 kHz

**Transistor rating @ 25°C

High-Performance Programmable Racing ESC

SMALL...LIGHTWEIGHT...EXTREMELY POWERFUL...EASY-TO-USE...RELIABLE.....any other requests?

You told us what you wanted in a programmable ESC, and here it is. The GTX is smaller & lighter than any other racing

speed control Novak has ever produced, and now it’s even easier to use. Right out of the box, this highly customizable ESC

is loaded with 7 factory-installed Throttle Programs, with the top pro driver’s favorite Profile always loaded as the default.

You choose how the GTX works best for you--select from the 7 factory programs, or customize the 7th program just how you want it.

Minimum Brake settings are individually stored for each program, and the 7th program lets you select from

7 Drive Frequencies, 5 Minimum Drive

percentages, 5 Brake Frequencies, 7 Minimum Brake percentages, 5 Dead Band percentages, 2 styles of braking, and 7 Drag Brake percentages.

The GTX has Novak’s

Variable Throttle Step Technology, with up to 2600 discrete steps

(1300 for drive & 1300 for braking)

for the smoothest ESC

available––no matter what frequency you select

(1-11kHz). As an added safeguard, your GTX is equipped with Thermal Overload Protection,

and that’s something that can save you some serious money considering the motors that are being used in today’s racing. Add to this the ease

& convenience of user-replaceable power wires, power capacitor, ON/OFF switch, & input harness, and the GTX is just what you asked for!

Because of this ESC’s advanced technical features, PLEASE READ ALL INSTRUCTIONS before using GTX

POWER CAPACITORS [#5675]

An external power capacitor is installed, and

SHOULD BE USED to

maintain cool and smooth operation.

Refer to Fig.5 Set-Up Photo

Replacement Power Capacitor is available in Novak kit #5675.

RACING SCHOTTKY MOTOR MODULES [#5636]

The GTX has a built-in 36A Schottky diode and does not require an

external one for most usage. The external Schottky will optimize the

ESC’s braking and motor performance in applications with heavy

or repeated braking or low-turn modified motors.

Racing Schottky Motor Module is available in Novak kit #5636.

MOTOR CAPACITORS [#5620]

Additional motor capacitors are available in Novak kit #5620.

14G SUPERFLEX SILICONE POWER WIRE [#5500 & 5505]

Replacement GTX battery & motor wire is available in Novak kits #5500

(36”red & 36”black) & #5505 (36”red & 36”blue).

12G SUPERFLEX SILICONE POWER WIRE [#5530 & 5535]

12 guage silicone battery & motor wire is available in Novak kits #5530

(36”red & 36”black) & #5535 (36”red & 36”blue).

GTX INPUT/SWITCH HARNESS [#5305]

The user-replaceable combo power switch/input harness comes

with ON/OFF switch and both long & short length input pigtails.

GTX Input/Switch harness available in Novak kit #5305.

WATER & ELECTRONICS DON’T MIX!

Never allow water, moisture, or other foreign materials to get

inside the speed control or on the PC Board.

Water damage will void the warranty!

DISCONNECT BATTERIES WHEN NOT IN USE

Always disconnect the battery pack from the speed control

when not in use to avoid short circuits and possible fire hazard.

4 TO 7 CELLS ONLY

Never use fewer than 4 or more than 7 cells (8.4 volts DC) in

the vehicle’s main battery pack.

NO REVERSE VOLTAGE!

Reverse battery polarity can damage speed control––Disconnect

the battery immediately if a reverse connection occurs.

POWER CAPACITOR RECOMMENDED

An external power capacitor is supplied & installed, and

SHOULD

be used with your GTX.

Failure to use Power Capacitor will result in

higher ESC operating temperatures & possible thermal shut-down!

TRANSMITTER ON FIRST

Always turn on the power of the transmitter first so that you

will have control of the vehicle when you turn it on.

INSULATE WIRES

Always insulate exposed wiring with heat shrink tubing or

electrical tape to prevent short circuits, which can damage ESC.

NO SOLVENTS

Exposing the speed control’s Lexan

®

case to any type of

solvents will damage the plastic.

NO CA GLUE

Exposure to CA glue or its fumes can cause damage to internal

components of the speed control and result in premature failure.

For proper ESC operation, adjust transmitter as follows:

A. Set HIGH ATV or EPA to maximum setting.

[amount of throw at full throttle]

B. Set LOW ATV, EPA, or ATL to maximum setting.

[amount of throw at full brakes]

C. Set EXPONENTIAL to zero setting.

[throttle channel linearity]

D. Set THROTTLE CHANNEL REV. SWITCH to either position.

E. Set THROTTLE CHANNEL TRIM to middle setting.

[adjusts neutral position/increases or decreases coast brakes]

F. Set ELECTRONIC TRIGGER THROW ADJUSTMENT to 70%

throttle and 30% brake throw (or 7:3).

[adjusts trigger throw electronic/digital pistol-grip transmitters]

G. Set MECHANICAL TRIGGER THROW ADJUSTMENT to position

with 2/3 throttle and 1/3 brake throw.

[adjusts trigger throw on mechanical/analog pistol-grip transmitters]

•NOT ALL TRANSMITTERS HA

VE THESE ADJUSTMENTS•

With GTX connected to

(at least)

a receiver & a charged battery pack:

1. TURN ON THE TRANSMITTER’S POWER

2. PRESS & HOLD GTX’S ONE-TOUCH/SET BUTTON

3. TURN ON THE SPEED CONTROL’S POWER

With transmitter throttle at neutral, and still pressing the SET button,

slide the GTX’s ON/OFF switch

to ON position.

4. CONTINUE HOLDING SET BUTTON UNTIL RED LED COMES ON

5. RELEASE GTX’S SET BUTTON AS SOON AS LED TURNS RED

6. PULL TRANSMITTER THROTTLE TO FULL-ON POSITION

Hold it there until the green status LED

turns solid green.

Note: Motor will not run during programming even if connected.

7. PUSH TRANSMITTER THROTTLE TO FULL-BRAKES

Hold it there until the green status LED

blinks green.

8. RETURN TRANSMITTER THROTTLE TO NEUTRAL

Red status LED will

turn solid red, indicating that throttle is at neutral,

and proper programming has been completed--you’re done.

NOTE: If transmitter setting are changed, programming must be repeated. If

you experience any problems, turn off ESC and repeat programming.

trouble-shooting guide

Steering Channel Works But Motor Will Not Run

• Check motor connections. Check motor and brushes.

• Make sure input signal harness is plugged into throttle channel of receiver

and the ESC. Check throttle channel operation with a servo. Check wiring

color sequence of receiver signal harness.

• Possible thermal shut-down (blue & red status LEDs flashing)––Check motor,

brushes, & drive train. ESC is being severely over-loaded.

• Possible internal damage––Refer to Service Procedures.

Receiver Glitches/Throttle Stutters During Acceleration

• Receiver or antenna too close to ESC, power wires, battery, or motor.

• Bad connections––Check wiring and connectors.

• Motor brushes worn––Replace brushes.

• Excessive motor current––Use milder motor or smaller pinion gear.

• External Power Capacitor damaged/not installed––Replace Power Capacitor.

Motor and Steering Servo Do Not Work

• Check wires, receiver signal harness wiring & color sequence, radio system,

crystals, battery & motor connectors, and battery pack.

• Possible internal damage––Refer to Service Procedures.

Model Runs Slowly/Slow Acceleration

• Check motor and battery connectors––Replace if needed.

• Bad battery or motor––Check operation with another.

• Incorrect transmitter/ESC adjustment––Refer to Steps 4 & 5.

• External Power Capacitor damaged/not installed––Replace Power Capacitor.

• Schottky diode damaged––If using external Schottky, check that diode is

installed correctly/Refer to Step 2. Possible internal Schottky damage.

Motor Runs Backwards

• Motor wired backwards––Check wiring and reverse.

• Backwards motor timing––Reverse motor end bell.

ESC Is Melted Or Burnt/ESC Runs With Switch Off

• Internal damage––Refer to Service Procedures.

*For more assistance call our Customer Service Department.

service procedures

Before sending your GTX in for service, review Trouble-Shooting guide &

instructions. ESC may appear to have failed when other problems exist.

After reviewing instructions, if you feel your GTX requires service, please

obtain the most current product service options & pricing by the following:

WEBSITE:

Print a copy of the

PRODUCT SERVICE FORM from the CUSTOMER

SERVICE section of the website. Fill out the needed information on this form

and return it with the Novak product that requires servicing.

PHONE/E-MAIL:

If you do not have access to the internet, contact our

customer service dept. by phone or e-mail as listed on the front page.

WARRANTY SERVICE:

For warranty work, you MUST CLAIM WARRANTY

on

PRODUCT SERVICE FORM & include a valid cash register receipt with

purchase date and dealer name & phone# on it, or an invoice from previous

service. If warranty provisions have been voided, there will be service charges.

GTX ESCs returned without a serial number will not be serviced under warranty.

ADDITIONAL NOTES:

• Hobby dealers or distributors are not authorized to replace Novak products

thought to be defective.

• If a hobby dealer returns your GTX for service, submit a completed

PRODUCT

SERVICE FORM to the dealer and make sure it is included with the ESC.

• Novak Electronics, Inc. does not make any electronic components

(transistors, resistors, etc.) available for sale.

product warranty

The GTX speed control is guaranteed to be free from defects in materials or workman-

ship for a period of 120 days from the original date of purchase (verified by dated,

itemized sales receipt). Warranty does not cover incorrect installation, components worn

by use, damage to case, damage from using fewer than 4 or more than 7 cells (1.2

volts DC/cell) input voltage, cross-connection of battery/motor, overheating solder

tabs, reverse voltage application, damage from incorrect installation of FET servo or

receiver battery pack, not installing three 0.1µF (50V) capacitors on motor, incorrect

installation of a Power Capacitor on the ESC or from using a damaged Power Capacitor,

using a non-Novak Power Capacitor, splices to input harness, damage from excessive

force when using the One-Touch/SET button or from disassembling case, tampering

with internal electronics, allowing water, moisture, or any other foreign material to

enter ESC or get onto the PC board, incorrect installation/wiring of input plug plastic,

allowing exposed wiring or solder tabs to short-circuit, or any damage caused by a

crash, flooding, or act of God.

In no case shall our liability exceed the product’s original cost. We reserve the right

to modify warranty provisions without notice.

Because Novak Electronics, Inc. has no control over the connection & use of the speed

control or other related electronics, no liability may be assumed nor will be accepted

for any damage resulting from the use of this product. Every Novak speed control is

thoroughly tested & cycled before leaving our facility and is, therefore, considered

operational. By the act of connecting/operating speed control, user accepts all resulting liability.

©2004 Novak Electronics, Inc. • All Rights Reserved • No part of these operating

instructions may be reproduced without the written permission of Novak Electronics,

Inc. • GTX Programmable Racing ESC, Variable Throttle Step Technology, Polar Drive

Technology, Radio Priority Circuitry, & One-Touch Set-Up are all trademarks of Novak

Electronics, Inc. • All Novak speed controls are designed & manufactured in the U.S.A.

BASIC SET-UP GUIDE -- GTX

PRECAuTIONS

optional accessories

Novak Electronics, Inc.

(949) 833-8873 • FAX (949) 833-1631

Customer Service e-mail:

Monday-Thursday: 8:00am-5:00pm (PST)

Friday: 8:00am-4:00pm

(closed every other Friday)

www.teamnovak.com

P1

P4

step

4

–

MOUNTiNG ESC

step

5

–

transmitter adjustments

step

6

–

one-touch programming

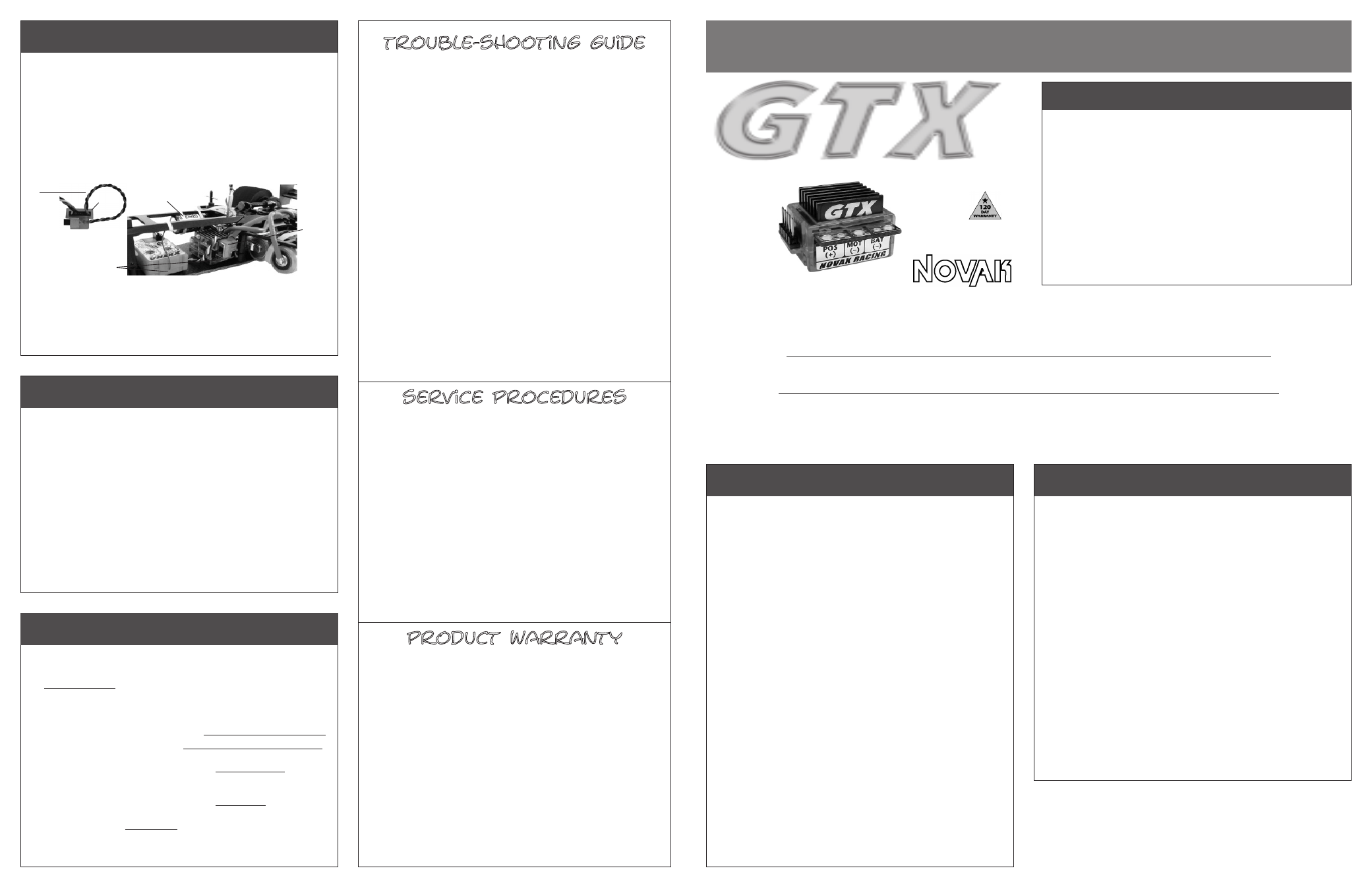

Be sure to mount the GTX where its power wires are away from other

electronics, and will not interfere with any moving parts.

• Mount GTX to the vehicle’s chassis with the included double-sided

tape

(use two layers of other double-sided tapes for adequate damping)

.

• Mount Power Capacitor to chassis with double-sided tape or tie-wrap.

If Power Cap. becomes dented/damaged, ESC failure can occur--replace

immediately.

Longer Power Capacitor wires decrease performance.

• You can use one of the included C-shaped plastic clips to secure

the ON/OFF switch to the side of the GTX’s black 5-pin power

switch/input harness plastic facing either forward or back

(see below)

.

Position switch against connector & slide clip over flange on switch.

• Be sure receiver & antenna are mounted as far from ESC, power

wires, battery, and servo as possible--these components all emit

RF noise when throttle is being applied. On graphite or aluminum

chassis vehicles, it may help to place receiver on edge with crystal

& antenna as far above chassis as possible.

Note: Mount antenna as close to receiver as possible--trail any excess wire off top

of antenna mast (cutting or coiling excess antenna wire will reduce radio range).

ON/OFF

switch

held with

C-clip

Power Capacitor

tie-wrapped to chassis

FIGURE 8

Electronics mounted

with double-sided tape

C-shaped clip holding

switch on black 5-pin

input harness plastic

clip