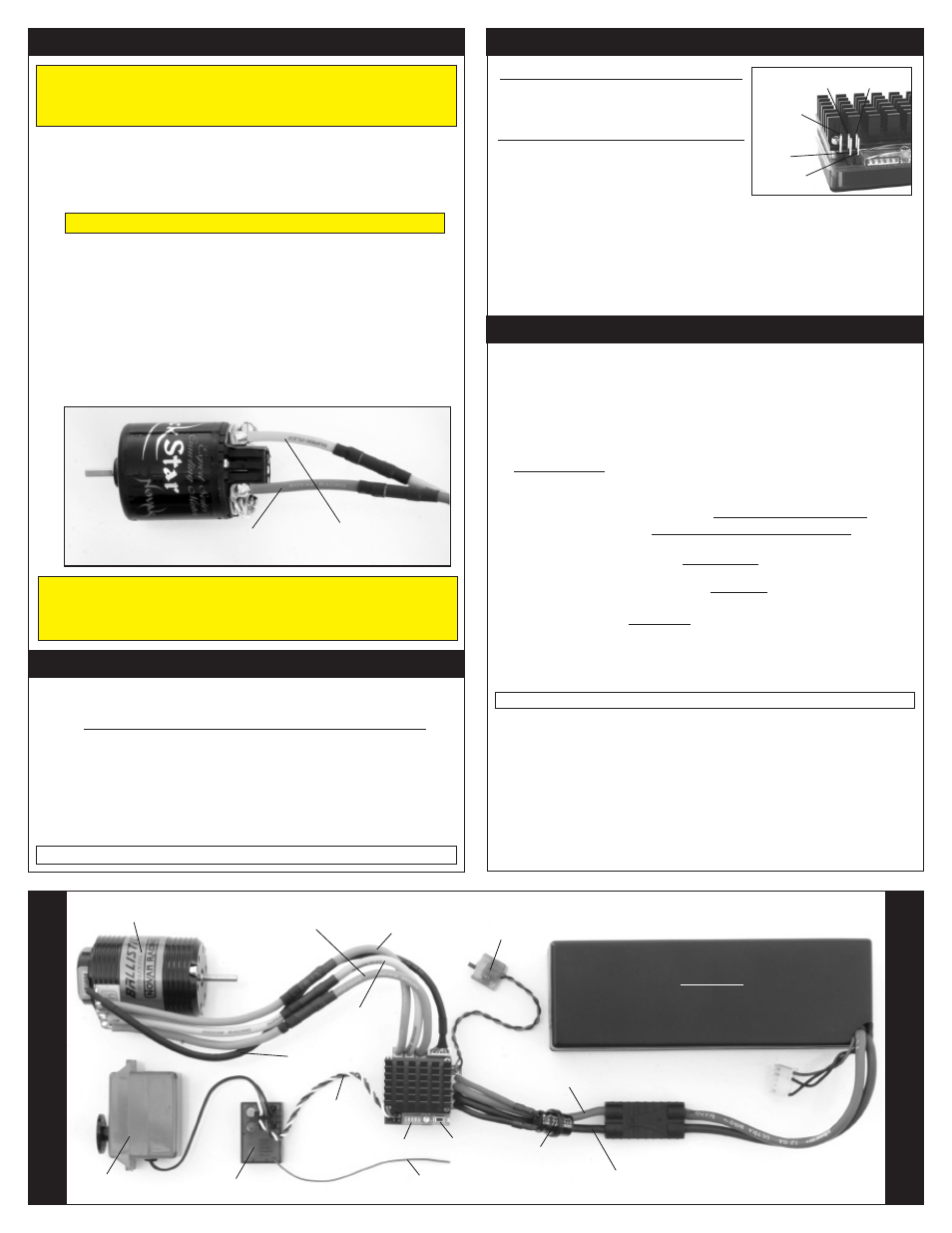

Step 2–connect motor, Step 5-one-touch set-up step 4–connect receiver, W.te am no va k. co m step 3–connect battery – Novak Brushed Speed Control: Eiger & Eiger Pro Basic Set-Up Guide (55-1835-1 Rev.6) User Manual

Page 2: Set-up photo, Receiver connection

black wire

(Rx negative)

red wire

(Rx positive)

white wire

(Rx signal)

positive

fan pin

negative

fan pin

yellow ESC motor power wire

to motor positive (+)

blue ESC motor power wire

to motor negative (–)

step 2–connect motor

1. SELECT PROPER MOTOR FOR OPTIMUM PERFORMANCE

The ESC’s different Drive/Brake Modes each work best with different motors.

Select the proper motor for the given application & DO NOT over-gear.

Brushless: Must be 2-pole, sensor-based, and mechanically timed to 30 deg.

2. INSTALL PINION GEAR & MOTOR

/

ADJUST PROPER GEAR MESH

Tighten pinion’s set screw on flat of motor shaft. Align pinion & spur gears.

A. You NEED a small amount of play between the pinion and spur gear

(about thickness of a piece of paper)–check free play at several points around

spur gear to ensure a proper mesh

(just in case gears are out of round).

MAKE SURE THE PINION/SPUR GEAR MESH IS NOT TOO TIGHT!

B. Tighten motor mounting screws–Avoid using excessive force that could

break screws or strip the threaded holes in motor.

3. CONNECT MOTOR POWER WIRES TO MOTOR (BRUSHED)

**Refer to STEP 5 “Brushless Motor Connection” for Brushless Motors**

The ESC’s motor leads come with Novak’s gold-plated bullet-style motor

connectors factory-installed for quick and easy motor connection. Motor

wire leads with bullet connectors are also included for use on motor.

A.

Connect the ESC’s

YELLOW silicone motor power wire to the bullet

connector on the motor’s

POSITIVE power wire.

B.

Connect

BLUE power wire to connector on motor’s NEGATIVE wire—You

may need to swap connectors (plus/minus) for proper motor rotation.

4. CHECK FOR PROPER GEARING DURING INITIAL RUNS

The brushless motor & ESC should NOT get hotter than 160°F--Crawler

motors

/

ESCs generally DO NOT get very hot. Reduce pinion size and check

the drive train for binding if you experience high operating temperatures.

ESC

ON/OFF

Switch

User-

replaceable

input signal

harness

(Ch.2)

Servo plugged into

steering ch. (#1)

Set

button

Status LEDs

Receiver

Trail excess wire off top

of antenna mast

Sensor-based 2-pole

brushless motor

Blue motor

power wire

(negative/Phase A)

Yellow motor

power wire

(positive/Phase B)

Orange motor power wire

--Used for Brushless ONLY--

(Phase C)

Sensor harness

Red power wire

(battery positive)

Black power wire

(battery negative)

PowerCap

(tie-wrapped to power wires)

Battery pack

• 2S or 3S* LiPo/LiFe or 4-9 cell NiMH/NiCd •

*external BEC required for 3S operation

ESC to be connected to a fully-charged battery pack and to the receiver

BRUSHLESS MOTORS:

Must perform One-Touch BEFORE motor wires are

connected. ESC must have motor sensor harness also plugged in:

> Insert the 6-pin connector of the motor’s sensor harness into ESC’s

sensor harness socket—note that the connector is keyed and can only insert

into the socket in one direction.

1. TURN ON THE TRANSMITTER’S POWER

2. PRESS & HOLD ESC’S ONE-TOUCH/SET BUTTON

3. TURN ON THE SPEED CONTROL’S POWER

With transmitter at neutral (still pressing SET button), slide ESC’s switch

to ON position.

4. CONTINUE HOLDING SET BUTTON UNTIL RED LED COMES ON

5. RELEASE SET BUTTON AS SOON AS RED LED TURNS ON

6. PULL TRANSMITTER THROTTLE TO FULL-ON POSITION

Hold it there until green status LED

turns solid green. (Motor won’t run during programming).

7. PUSH TRANSMITTER THROTTLE TO FULL-BRAKE/REVERSE

Hold it there until the green status LED

blinks green.

8. RETURN TRANSMITTER THROTTLE TO NEUTRAL

The red status LED will

turn solid red, indicating that speed control is at neutral and

that proper programming has been completed.

If transmitter settings are changed, the One-Touch Set-Up must be repeated.

If you experience any problems, turn off ESC and repeat One-Touch; If

problems persist, refer to ‘Transmitter Adjustments’ in Eiger Field Guide.

NOTE: ESC reverts back to factory-default settings when One-Touch Set-Up is performed.

---BRUSHLESS MOTOR CONNECTION---

2-pole, sensor-based brushless motors, mechanically timed to 30° ONLY

Refer to Set-Up Photo below

A.

Change the Throttle Profile to Brushless Mode (setting #2). Refer to

Eiger Field Guide for programming instructions.

B.

Connect the ESC’s

BLUE silicone motor power wire to the bullet connector

on the motor’s

PHASE “A” power wire.

C.

Connect

YELLOW power wire to connector on motor’s PHASE “B” wire.

D.

Connect

ORANGE power wire to connector on motor’s PHASE “C” wire.

STEP 5-one-touch set-up

step 4–connect receiver

receiver connection

The ESC has a user-replaceable input harness

with a 2mm mini plug on ESC end of it and the

industry-standard connector on receiver end.

ESC works with all major brand’s new receivers

(very old receivers need wiring sequence changed in

plastic plug on receiver end--

Damage may occur

if sequence is incorrect)

.

For instructions on

changing the wiring sequences, visit our web site.

1. CONNECT 2mm MINI PLUG TO RECEIVER HARNESS PINS ON ESC

Insert the 2mm mini plug of receiver input harness onto the receiver harness

3-pin header on the ESC.

White wire goes on the left side pin as shown above.

2. CONNECT RECEIVER HARNESS TO RECEIVER

Insert 3-pin connector of receiver harness into Ch.2 (throttle) slot of receiver.

3. INSTALL 25mm COOLING FAN ON ESC (OPTIONAL)

Press fan screws through 2 of the holes along one edge of the fan and into the 1st

gap of ESC heat sink fins. Plug fan connector onto ESC’s fan pins--note polarity.

set-up photo:

BRUSHLESS

w

w

w

.te

am

no

va

k.

co

m

step 3–connect battery

1. INSTALL PROPER BATTERY CONNECTOR TO ESC

(

if needed

)

If necessary, solder the appropriate connector to the ESC’s

RED & BLACK

battery power wires if needed to match your battery packs.

We suggest using low-loss high power battery connectors like the Dean’s Ultra

Plug or the Novak Power Connector (Novak part #5750).

• Use polarized connectors. Reverse voltage will damage ESC & void warranty.

• Use female connectors on battery packs & insulate exposed wiring to avoid shorts.

2. MAKE SURE ESC’S POWER SWITCH IS TURNED “OFF”

3. CONNECT ESC TO BATTERY PACK

Plug the ESC’s battery connector into a fully charged 2S-3S LiPo/LiFe, or

4-9 cell NiMH (1.2 VDC/cell) battery pack.

If using NiMH cells, Voltage Cut-Off Circuitry must be turned OFF (refer to ESC Field Guide)

*Battery pack, servo, receiver,

battery connector, and motor

are not included.

• Novak R/C •

19 Rancho Circle, Lake Forest, CA 92630 • 949-916-6044