Custom programming options -- advanced, Minimum brake, Drag brake – Novak Brushless Speed Control: Drift Spec Track Guide (55-3074P-1 Rev.1) User Manual

Page 2: Minimum drive, Dead band, Brake frequency, Drive frequency, Reverse, Voltage cut-off, Hall sensor test

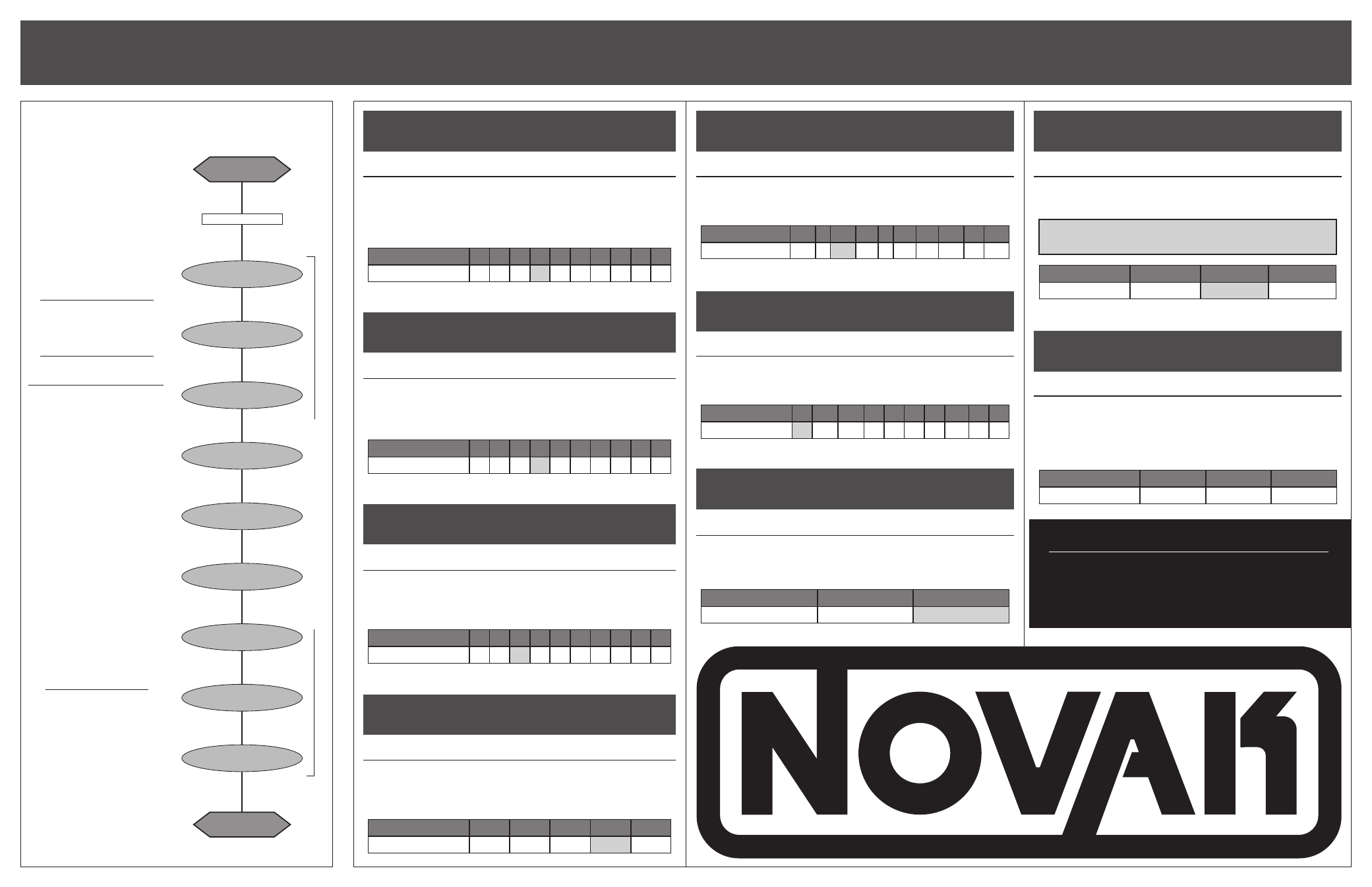

esc software flow chart

CUSTOM programmiNG options -- advanced

This ESC features several different

parameters that can be customized

to fine-tune the ESC’s feel &

response to your liking.

The flow chart below and the

adjustment steps to the right

describe the different parameters

and how they effect the ESC.

One-Touch Programming must be

completed before customization of

parameters, as all ESC parameters

are defaulted back to the factory

settings whenever the One-Touch

Programming is performed.

DEFAULT SETTINGS FOR

THE ESC PARAMETERS ARE

LISTED IN BOLD IN THE

TABLES TO THE RIGHT

TO CHANGE PARAMETER SETTINGS:

1. CONNECT THE ESC TO A

CHARGED BATTERY PACK,

RECEIVER, AND MOTOR’S

SENSOR HARNESS.

2. SLIDE THE ESC’s ON/OFF

SWITCH TO ‘ON’ POSITION

3. WITH ESC AT NEUTRAL, PRESS

& HOLD SET BUTTON

Release ESC’s SET button once LEDs

are lit for the desired setting.

To skip a parameter, continue

to press & hold SET button until

desired parameter is reached.

4. SELECT PARAMETER VALUE

LED flashes to indicate active

setting (refer to tables at right).

Quick press & release SET button

to select desired setting.

5. PRESS & HOLD SET BUTTON

TO STORE NEW SELECTION

When SET button is pressed and

held for about 1 second,

the

new selection is stored in ESC’s

memory—Status LEDs will scroll across

to indicate ESC is exiting programming

& ESC returns to neutral.

There is no time constraint during

selection of custom parameters.

minimum brake

#1 MINIMUM BRAKE SETTINGS

(1 of 10)

BLUE LED

Amount of braking applied with the first pulse of transmitter braking information sent.

>> Increasing this setting starts the braking at a stronger/higher

level. This is useful to compensate for heavier vehicles to minimize the

amount of trigger throw required before effective braking is applied.

Note: Blue LED will be ON when ESC is at neutral if this setting is above 0%.

Setting

(# of flashes)

1

2

3

4

5

6

7

8

9 10

Minimum Brake (%):

0

3

6

9 12 15 18 24 30 40

drag brake

#2 DRAG BRAKE SETTINGS

(1 of 10)

BLUE & YELLOW LEDs

Amount of braking being applied while transmitter is at neutral. AKA ‘coast’ brakes.

>> Increasing this setting makes the motor slow down more without

pushing the transmitter’s trigger into the brake/reverse direction.

Note: Yellow LED will be ON when ESC is at neutral if this setting is above 0%.

Setting

(# of flashes)

1

2

3

4

5

6

7

8

9 10

Drag Brake (%):

0

3

6

9 12 15 18 24 30 40

minimum drive

#3 MINIMUM DRIVE SETTINGS

(1 of 10)

YELLOW LED

Amount of forward drive applied with first pulse of transmitter throttle information sent.

>> Increasing this setting starts the forward drive at a stronger/higher

level. This is useful to compensate for heavier vehicles to minimize the

amount of trigger throw required before effective drive is applied.

Setting

(# of flashes)

1

2

3

4

5

6

7

8

9 10

Minimum Drive (%):

0

1

2

3

4

6

8 10 12 15

dead band

#4 DEAD BAND SETTINGS

(1 of 5)

BLUE & GREEN LEDs

The space between Minimum Brake and Minimum Drive, with Neutral in the middle.

>> Increasing this setting increases amount of ‘free play’, or distance the

transmitter’s trigger must move before forward drive or braking begins.

This is useful for transmitter triggers that don’t center accurately or have worn pots.

Setting

(# of flashes)

1

2

3

4

5

Dead Band (%):

2

3

4

5

8

BRAKE FREQUENCY

#5 BRAKE FREQUENCY SELECTION

(1 of 10)

RED LED

How the ESC’s braking response feels with respect to the transmitter’s trigger input.

>> Increasing the Brake Frequency makes the brake response feel

smoother and more controllable.

Setting

(# of flashes)

1

2

3

4

5

6

7

8

9

10

Brake Freq. (KHz):

1.67 2 2.25 2.5 3 3.5 4.5 5.75 10 13.7

DRIVE FREQUENCY

#6 DRIVE FREQUENCY SELECTION

(1 of 10)

GREEN LED

How the ESC’s throttle response feels with respect to the transmitter’s trigger input.

>> Increasing the Drive Frequency makes the throttle response feel

smoother and more controllable.

Setting

(# of flashes)

1

2

3

4

5

6

7

8

9 10

Drive Freq.

(KHz)

:

32

27

24

22 21 16 13 10

8

6

reverse

#7 REVERSE SELECTION

(1 of 2)

YELLOW-GREEN-RED LEDs

>> Changing this setting activates or deactivates the speed control’s

motor reversing functionality. When OFF, the ESC has forward and

brakes only. When ON, the ESC has forward with brakes, then reverse

with a second push of trigger after braking to a slow speed.

Setting

(# of flashes)

1

2

Reverse:

OFF

ON

voltage cut-off

#8 VOLTAGE CUT-OFF SELECTION

(1 of 3)

YELLOW & RED LEDs

>> Changing this setting enables or disables the ESC’s built-in Smart

Stop cut-off circuitry, and sets the voltage cut-off point based on what

type of batteries are being used in the vehicle’s main battery pack.

DO NOT USE LiPo/LiFe BATTERIES WITH THE ESC’S

VOLTAGE CUT-OFF CIRCUITRY TURNED OFF

Setting

(# of flashes)

1

2

3

Voltage Cut-Off Type:

OFF

(NiMH/NiCd)

LiPo

LiFe

hall sensor test

#9 MOTOR SENSOR TEST

BLUE-YELLOW-RED LEDs

>> This is a diagnostic feature that allows you to easily check the

functionality of your brushless motor’s hall effect sensors & sensor

harness and its connections at the speed control and motor. Once

activated, slowly rotate the motor’s output/pinion shaft and the

appropriate LED will light up if a signal is received for its sensor in

the motor. Refer to ‘MOTOR HALL SENSOR TEST’ section.

Motor Hall Sensor

A

B

C

LED Color:

BLUE

YELLOW

RED

restoring factory defaults

Every time the speed control’s

One-Touch Programming is performed,

the ESC will automatically revert back

to the factory default settings.

@NEUTRAL

RED LED on solid

MIN. BRAKE

BLUE

DRAG BRAKE

BLUE & YELLOW

DEAD BAND

BLUE & GREEN

MIN. DRIVE

YELLOW

press & hold SET button

continue holding ESC’

s SET button to skip steps here

VOLTAGE CUT-OFF

YELLOW & RED

BRAKE FREQ.

RED

DRIVE FREQ.

GREEN

REVERSE

YELLOW-GREEN-RED

HALL SENSOR TEST

BLUE-YELLOW-RED

@NEUTRAL

RED LED on solid