2 hydraulic installation, 1 roll cylinder installation – NORAC 4467BC+4B User Manual

Page 14

11

4.2 H

YDRAULIC

I

NSTALLATION

WARNING!

The hydraulic system creates very

high pressure. Before disconnecting

any hydraulic lines ensure all pressure

has been bled from the system.

When changing the boom hydraulic

hoses leave the booms in

TRANSPORT POSITION.

IMPORTANT:

Component failure due to oil

contamination is not covered under

the UC4+ Spray Height Control

warranty. It is recommended that a

qualified technician does the hydraulic

installation.

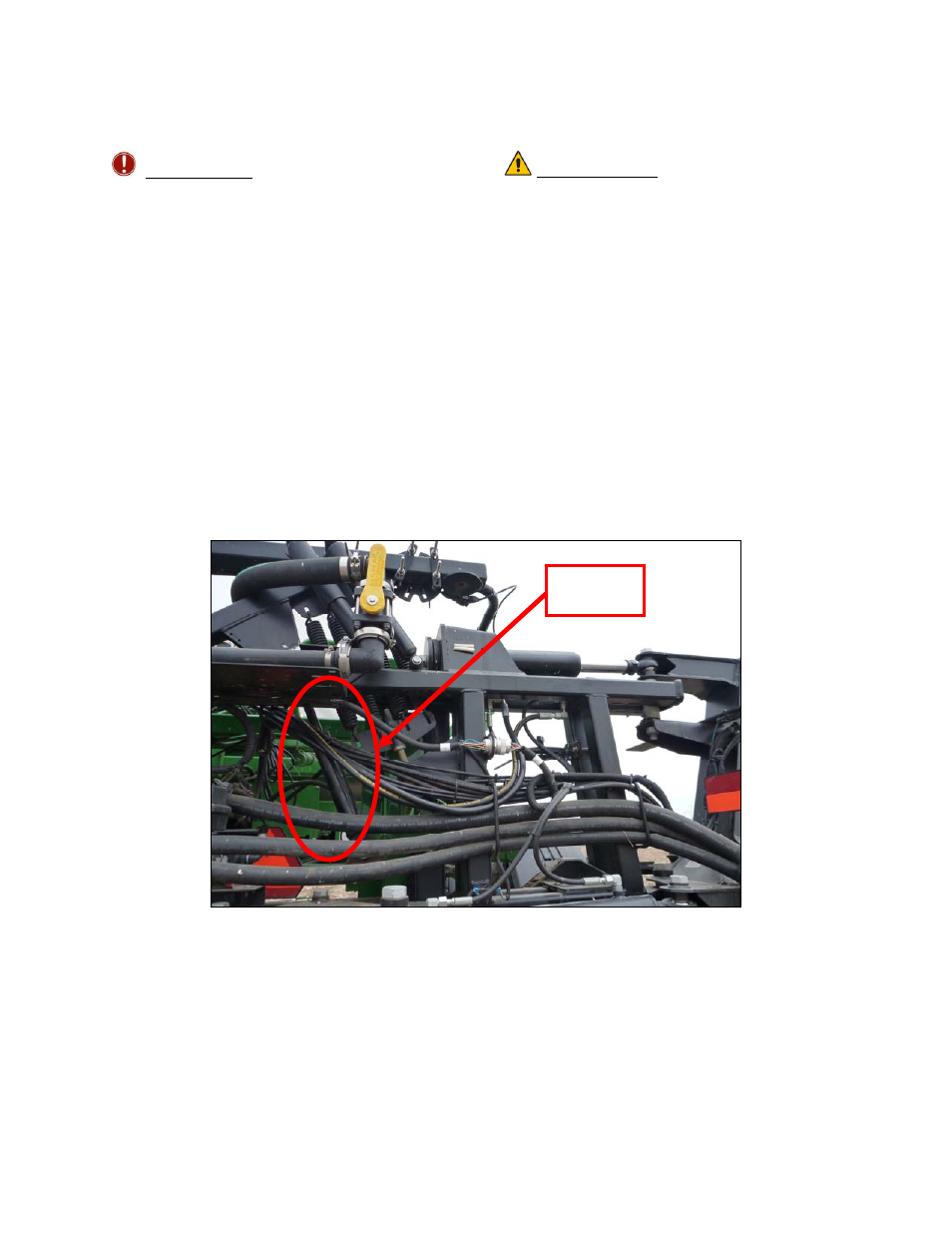

4.2.1 Roll Cylinder Installation

1. Remove the link arm (black square

tube) connected between the parallel lift

frame and roll frame. See Figure 10

for the link arm location.

2. Install the roll cylinder (H75) in place of

the link arm (Figure 11). When doing

this the top pin in the link arm must be

replaced with the supplied pin (B18).

The snap ring on the existing pin can be

used.

Figure 10: John Deere Link Arm Location

3. Install the 6MB-6MOR (F12) fittings

into the cylinder.

4. Install the 4MOR-4FORX90 (F14)

fitting onto the cylinder fitting at the cap

end of the cylinder.

5. When the cylinder is installed the

bottom bolt must be tightened to 266

ft-lbs (350 Nm) and there should be no

slop or free-play on the bottom bolt or

the top pin. Any free movement will

drastically reduce the active roll

performance.

Link Arm

Position