Install machine supports, Table 11 — marine waterbox cover weights, Table 12 — nih waterbox cover weights – Carrier Centrifugal Liquid Chiller 19EX User Manual

Page 14

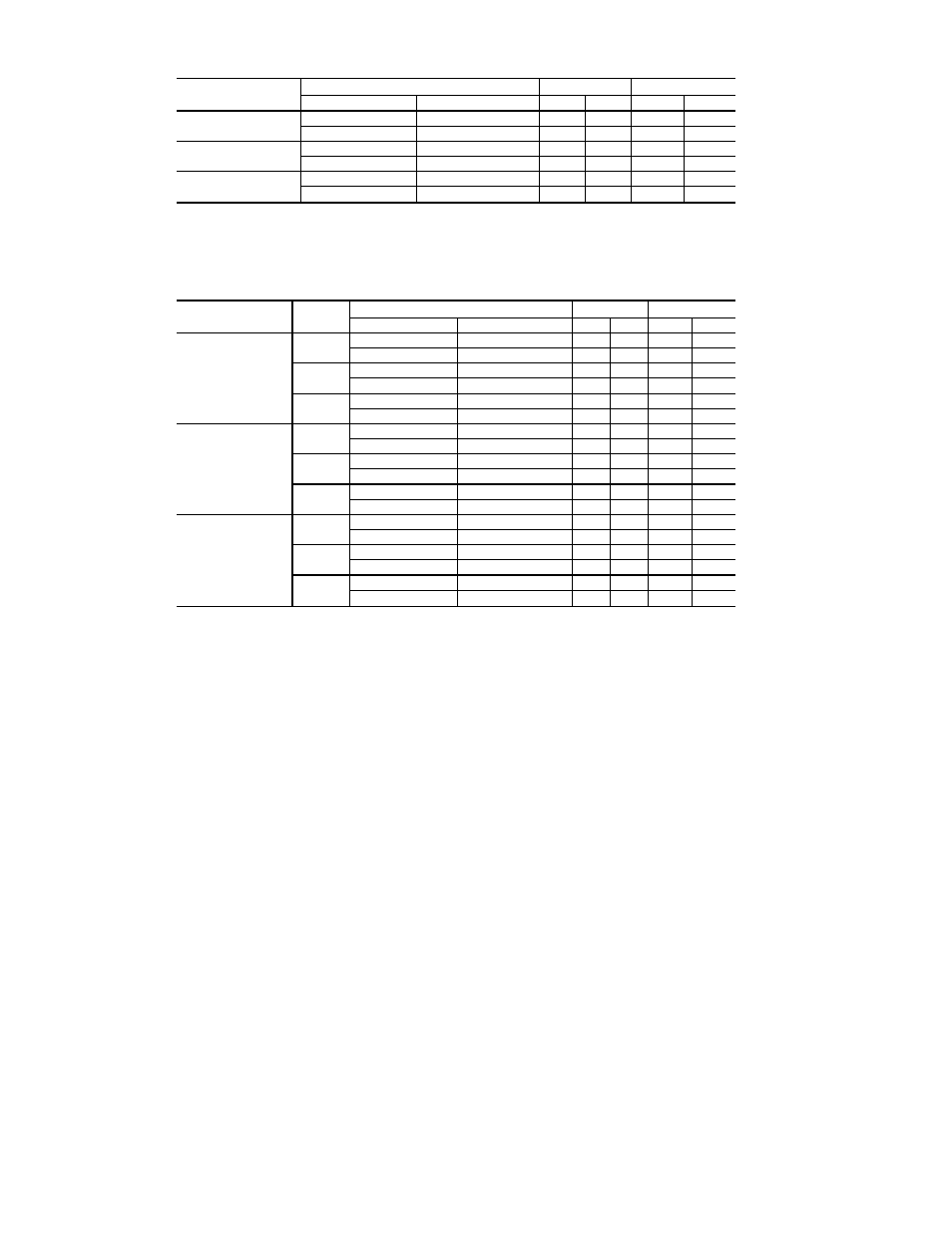

Table 11 — Marine Waterbox Cover Weights*

HEAT EXCHANGER

SIZE

DESIGN MAXIMUM WATER PRESSURE

COOLER

CONDENSER

psi

kPa

lb

kg

lb

kg

31 - 33

150

1034

1667

756

1092

495

300

2068

2280

1034

1436

651

41 - 48

150

1034

2236

1015

1275

579

300

2068

3060

1389

1660

754

51 - 57

150

1034

—

—

1643

746

300

2068

—

—

2243

1018

*Heat exchangers with marine waterboxes have heavier dry and operating weights than heat exchangers with nozzle-

in-head waterboxes.

Table 12 — NIH Waterbox Cover Weights*

HEAT EXCHANGER

SIZE

PASSES

DESIGN MAXIMUM WATER PRESSURE

COOLER

CONDENSER

psi

kPa

lb

kg

lb

kg

31 - 33

1

150

1034

1880

853

—

—

300

2068

2748

1247

—

—

2

150

1034

2168

983

1356

615

300

2068

3107

1409

1959

889

3

150

1034

2105

955

1283

582

300

2068

2991

1357

1828

829

41 - 48

1

150

1034

2997

1361

1735

788

300

2068

4225

1918

2510

1140

2†

150

1034

2984

1355

1885

856

300

2068

4188

1901

2590

1176

3

150

1034

3035

1378

1777

807

300

2068

4244

1927

2539

1153

51 - 57

1

150

1034

—

—

2032

923

300

2068

—

—

2940

1335

2†

150

1034

—

—

2649

1203

300

2068

—

—

3640

1653

3

150

1034

—

—

—

—

300

2068

—

—

—

—

NIH — Nozzle-in-Head

*The 150 psig (1034 kPa) 2-pass waterbox cover weights are included in the dry weight shown in Table 1.

†Two different waterbox covers are present on 2-pass machines. The weight shown in this table represents the weight

of the waterbox cover that contains the nozzles. A blank waterbox cover is also present on 2-pass units. The weight

of the blank waterbox cover is identical to the weight of the same size marine waterbox cover. Refer to Table 11.

Install Machine Supports

INSTALL STANDARD ISOLATION — Figures 10 and 11

show the position of support plates and shear flex pads, which

together form the standard machine support system.

INSTALL OPTIONAL ISOLATION (if required) — Un-

even floors or other considerations may dictate the use of

soleplates and leveling pads. Refer to Fig. 10 and 11.

Level machine by using jacking screws in isolation sole-

plates. Use a level at least 24 in. (600 mm) long.

For adequate and long lasting machine support, proper grout

selection and placement is essential. Carrier recommends that

only pre-mixed, epoxy-type, non-shrinking grout be used for

machine installation. Follow manufacturer’s instructions in

applying grout.

1. Check machine location prints for required grout

thickness.

2. Carefully wax jacking screws for easy removal from grout.

3. Grout must extend above the base of the soleplate and

there must be no voids in grout beneath the plates.

4. Allow grout to set and harden, per manufacturer’s in-

structions, before starting machine.

5. Remove jacking screws from leveling pads after grout has

hardened.

INSTALL SPRING ISOLATION — Field-supplied spring

isolators may be placed directly under machine support plates

or be located under machine soleplates. Consult job data for

specific arrangement. Low profile spring isolation assem-

blies are recommended so that the machine is kept at a con-

venient working height inside of the tube sheet.

Obtain specific details on spring mounting and machine

weight distribution from job data. Also, check job data for

methods for supporting and isolating pipes that are attached

to the spring-isolated machines.

14