LAARS Pennant PNCV (Sizes 500-2000) - Install and Operating Manual User Manual

Page 38

LAARS Heating Systems

Page 38

APPLICATION

MODE

SYSTEM

SETTING

SENSORS USED

• Parallel piping (non-

primary/secondary)

hydronic system

1

• None

• DHW with or without

a tank aquastat

• Primary/secondary

hydronic system

2

• Laars System

(preferred by Laars)

Sensor (shipped

• No outdoor reset

with each Pennant)

• Parallel piping (non-

primary/secondary)

hydronic system

3

• Laars System

• DHW

Sensor (shipped

• Advanced control

(with each Pennant)

capability

• No outdoor reset

• Parallel piping (non-

• Laars outdoor reset

primary/secondary)

sensor (optional

hydronic system

4

part #R2014000)

• Advanced control

capability

• Outdoor reset

• Primary/secondary

• Laars System

hydronic system

5

Sensor (shipped

(preferred by Laars)

with each Pennant)

• Outdoor reset

• Laars outdoor reset

sensor (optional part

# R2014000)

• Building automation

control

• Multiple boiler system

6

• None

control

• Energy management

system

• Other external control

Table 11. Modes and Sensors for Applications.

install the extra sensor if required for that mode. See

Sections 6.3.1 and 6.3.2

for more information, or

contact the factory.

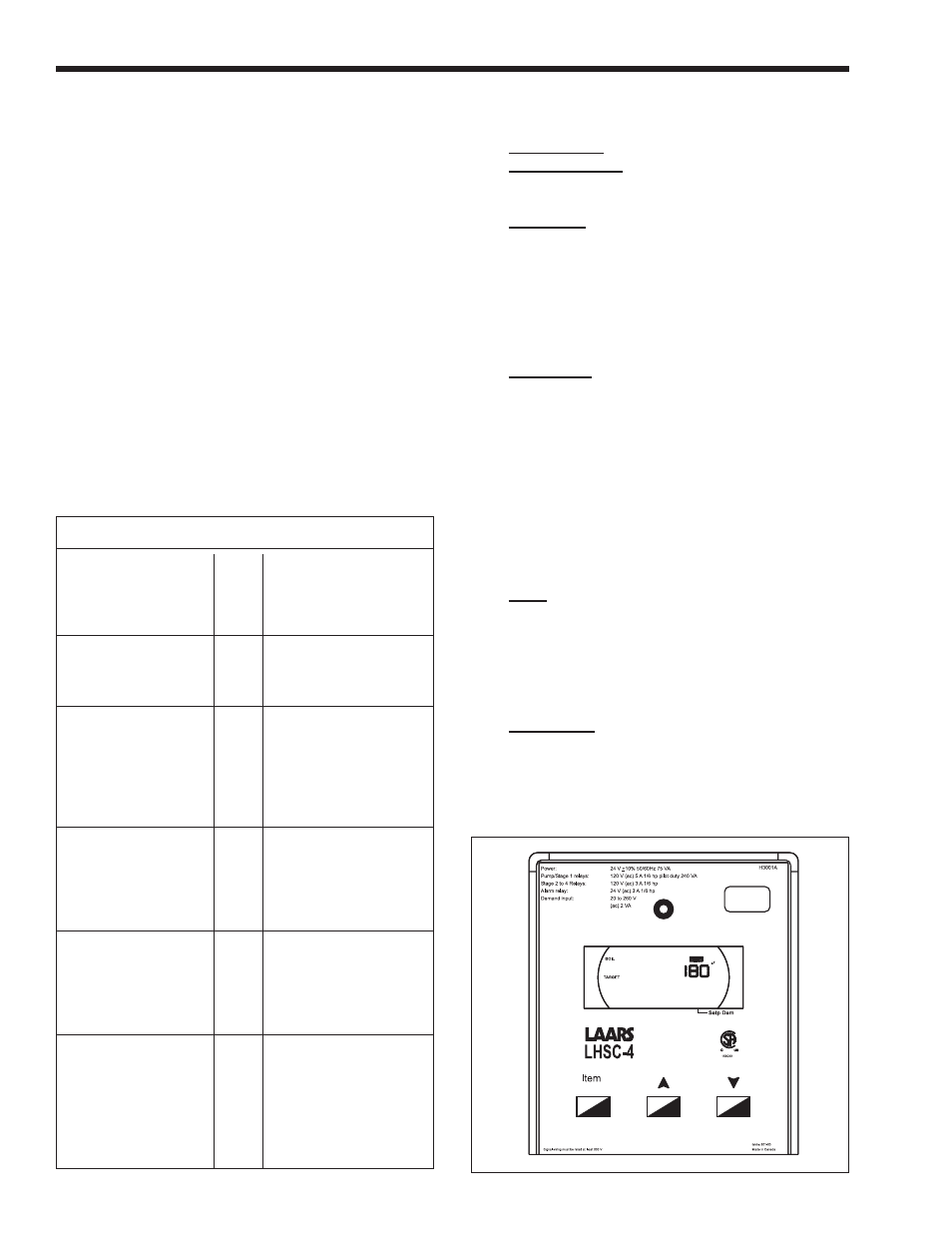

There are three black programming buttons on

the Temperature Control (see

Figure 25

). Press and

hold all three programming buttons until the word

ADJUST appears in the upper right corner of the LCD

display (it replaces the word

VIEW).

Pressing

ITEM

cycles you through the items you

need to program.

UP ARROW

increases the value of

that item, while

DOWN ARROW

decreases it.

ADJUST

mode exits if you don’t press a button for 20 seconds.

To return to

ADJUST mode, simply press and hold

the three buttons again.

The first item is

MODE; enter the mode number

as determined above. The Temperature Control will

then present you with some or all of the following

options, depending on the mode you have chosen:

In mode 6 (external boiler control), you will not

see the following options. Refer to

Section 6.4.10

for

setup information for mode 6.

FOR ALL OTHER MODES:

BOIL MASS (Boiler Mass): Always choose “1”.

BOIL TARGET (Boiler Target Temperature):

Your desired set-point temperature. See

Section 6.4.5

and

Figure 26

for more information.

BOIL MIN (Boiler Minimum Temperature): This

setting tells the Temperature Control to maintain at

least this temperature, even if the PID logic determines

a lower setting would save energy. The BOIL MIN

should always be 120°F (49°C) or higher to prevent

condensation, and can be set up to 10°F below your

BOIL TARGET temperature. See

Section 6.4.3

for

more information.

BOIL MAX (Boiler Maximum Temperature):

This setting tells the Temperature Control to limit the

maximum outlet temperature to this setting or below,

and determines how quickly the temperature control

“stages down” or off. If the BOIL MAX setting is

much higher than the BOIL TARGET temperature, the

temperature control will fire all stages until the target

temperature is reached, and then shut down all stages

at once. To enable gradual staging down of the boiler

as you approach your target temperature, set the BOIL

MAX to the same setting as the target temperature. See

Section 6.4.4

for more information.

DIFF (Boiler Differential): This setting is divided

above and below the target temperature. The water

will be allowed to cool ½ this setting below the target

temperature before first stage fires, and will heat to ½

this setting above the target temperature before staging

the boiler down. See

Section 6.4.1

and

Figure 28

for

more information.

PUMP DLY (Pump Delay): On pump mounted

units, the boiler mounted pump continues to run for

the time selected after the heat demand in the system

is satisfied. This setting also affects the 24VAC output

on the “PMP” “PMP” terminals (see

Section 5.2

).

Figure 25. Temperature Control.