Caution, Start--up, Preliminary checks – Carrier 40QNQ User Manual

Page 20: Evacuate and dehydrate the system

20

START--UP

Preliminary Checks

1. Check condensate drainage system; on the opposite side of

the drain connection, insert a water bottle up into the fan

coil unit and fill the drain pan. Water must flow steadily; if

not, check the pipe slope or inspect for any pipe restrictions.

2. Make sure all wiring connections are correct and they are

tight.

3. Field electrical power source must agree with unit name

plate rating.

4. Check that all barriers, covers, and panels are in place. En-

sure that the filters and return--air grilles on the indoor unit

have been installed and that the discharge louvers are posi-

tioned correctly.

5. All service valves must be closed.

6. On units with crankcase heaters, ensure belly--band heaters

are tight around the compressor.

Evacuate and Dehydrate the System

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage

or improper operation.

Never use the system compressor as a vacuum pump.

Using Vacuum Pump

1. Completely tighten flare nuts A, B, C, D, connect manifold

gage charge hose to a charge port of the low side service

valve. (See Fig. 34.)

2. Connect charge hose to vacuum pump.

3. Fully open the low side of manifold gage. (See Fig. 35)

4. Start vacuum pump

5. Evacuate using either deep vacuum or triple evacuation

method.

6. After evacuation is complete, fully close the low side of

manifold gage and stop operation of vacuum pump.

7. The factory charge contained in the outdoor unit is good for

up to 25 ft. (8 m) of line length. For refrigerant lines longer

than 25 ft (8 m), add 0.3 oz. per foot of extra piping up to

the maximum allowable length.

8. Disconnect charge hose from charge connection of the low

side service valve.

9. Fully open service valves B and A.

10. Securely tighten caps of service valves.

Outdoor Unit

Indoor Unit

Refrigerant

Service Valve

Low Side

High Side

A

B

C

D

A07360

Fig. 34 -- Service Valve

Manifold Gage

500 microns

Low side valve

High side valve

Charge hose

Charge hose

Vacuum pump

Low side valve

A07361

Fig. 35 -- Manifold

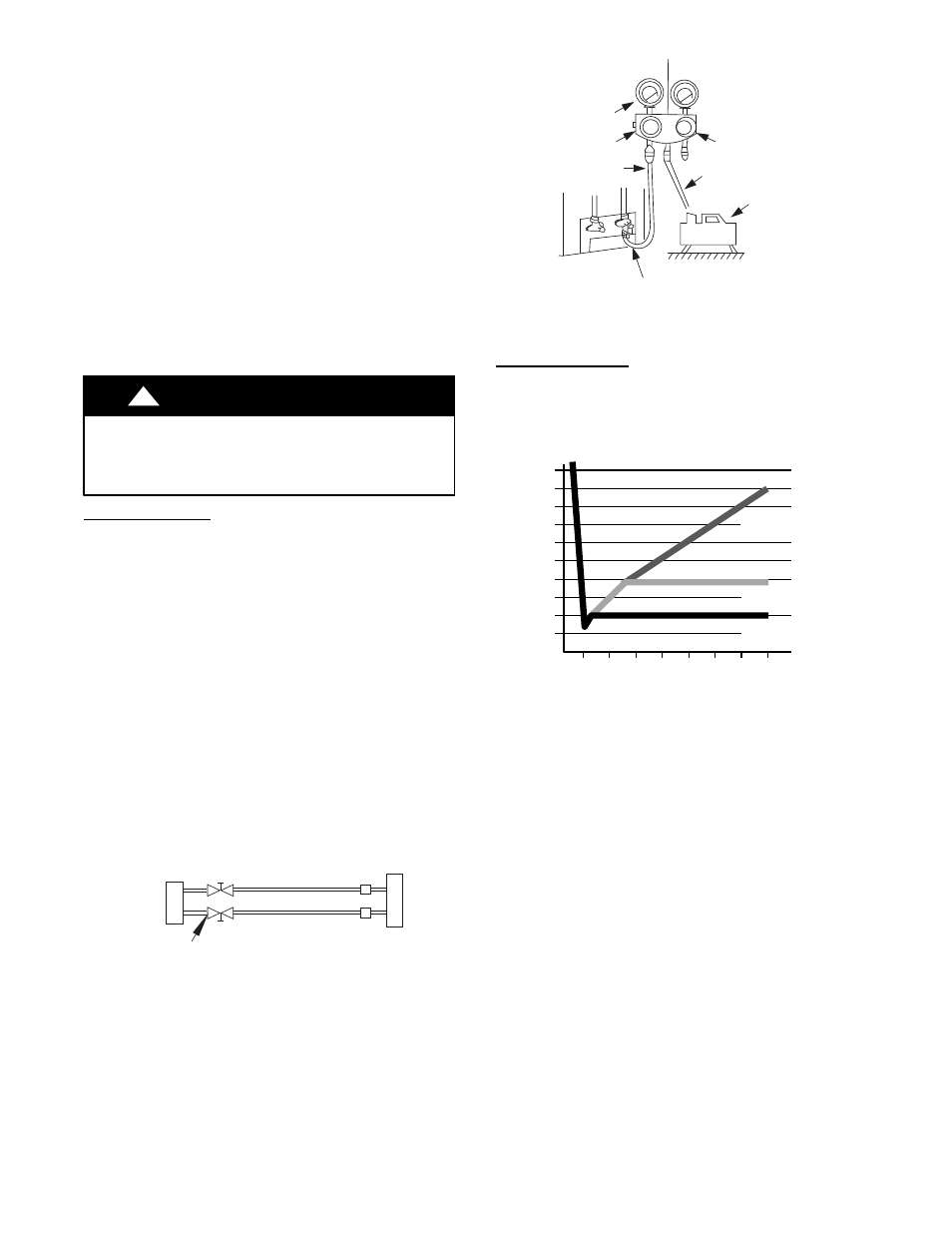

Deep Vacuum Method

The deep vacuum method requires a vacuum pump capable of

pulling a vacuum of 500 microns and a vacuum gage capable of

accurately measuring this vacuum depth. The deep vacuum method

is the most positive way of assuring a system is free of air and

liquid water. (See Fig. 36)

500

MINUTES

0

1

2

3

4

5

6

7

1000

1500

LEAK IN

SYSTEM

VACUUM TIGHT

TOO WET

TIGHT

DRY SYSTEM

2000

MI

CRONS 2500

3000

3500

4000

4500

5000

A95424

Fig. 36 -- Deep Vacuum Graph