Carrier 06D User Manual

Page 16

16

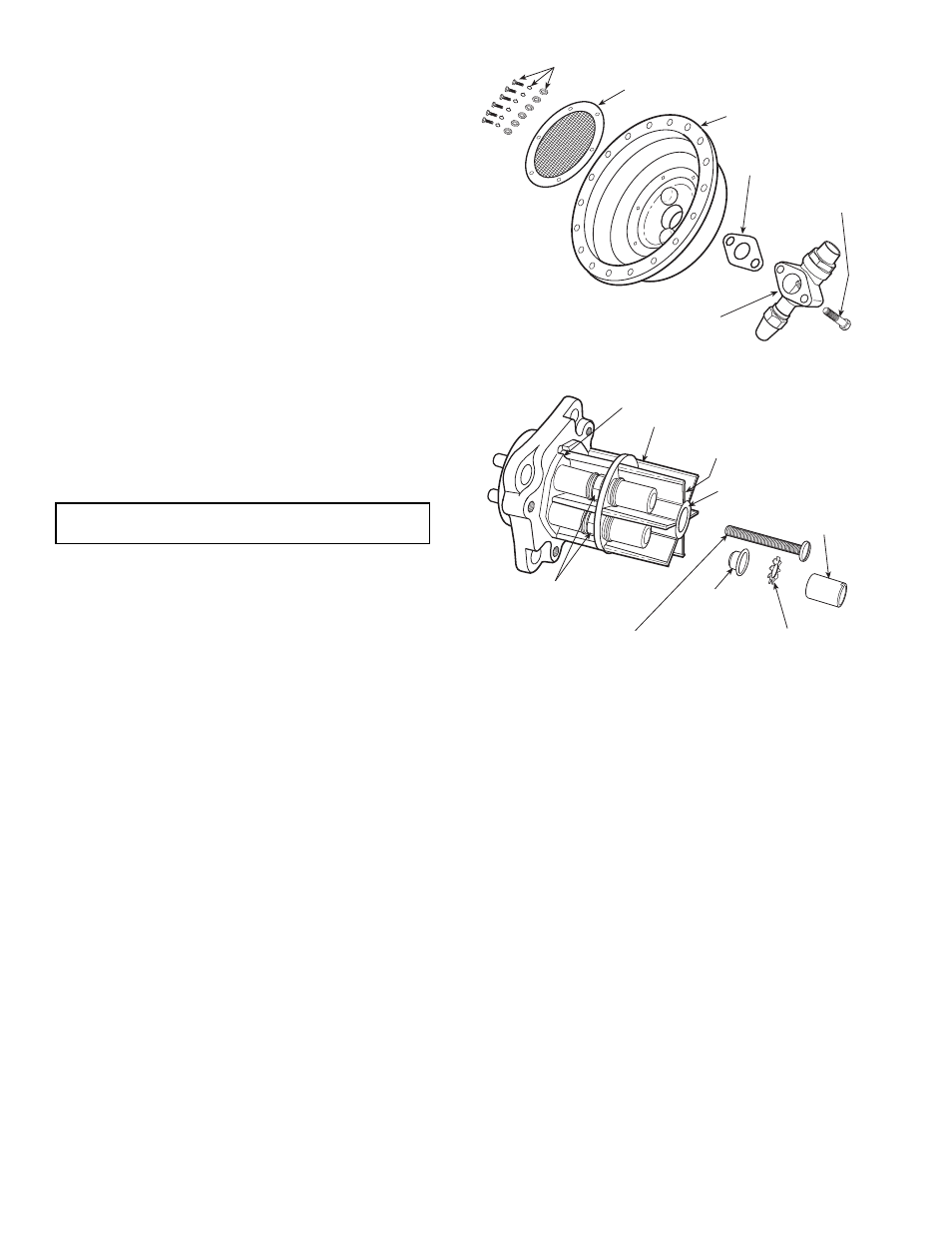

Cleaning Suction Strainer

1. Pump down compressor.

2. Remove motor end cover and screws holding disc type

strainer (Fig. 18) to cover.

3. Clean strainer with solvent or replace if broken or

corroded.

4. Replace strainer and motor end cover. Purge or evacuate

compressor before starting.

Motor Replacement —

Stator and rotor are not field

replaceable. Stator is a press fit into motor housing. If compres-

sor motor is damaged, replace compressor.

Terminal Plate Assembly —

The terminal plate assem-

bly is shown in Fig. 19. Do not disassemble for any reason ex-

cept to replace the phase barrier, which may become damaged.

If refrigerant leakage or a ground short occurs, the entire ter-

minal plate assembly must be replaced.

If it becomes necessary to remove the phase barrier, proceed

as follows:

1. Loosen and remove all terminal nuts.

2. Remove lock washers and wire terminals.

3. Loosen and disengage the center screw. (Do not try to

remove the screw.)

4. Lift the phase barrier off the terminal screws (the spacers

and the center screw are removed with the phase barrier).

Procedure for reassembling the phase barrier:

1. Place phase barrier over the terminal screws. Be sure po-

sitioning key is in the recess in the terminal plate before

proceeding further.

2. Place the spacers and wire terminals on the terminal

screws.

3. Place the lock washers and terminal nuts over the wire

terminals and tighten to specified torque (18 to 30 lb-in.).

4. Install the center screw through the phase barrier and

tighten to the specified torque (15 to 25 lb-in.).

NOTE: The design allows for clearance between the center

screw head and the phase barrier. Thus, the torque limit may

be reached before the screw head contacts the phase barrier.

This condition is acceptable.

Compressor Running Gear Removal

1. Remove pump end bearing head.

2. Remove motor end cover carefully to prevent damage to

stator. Support cover and lift off horizontally until it clears

windings.

3. Remove bottom cover plate.

4. Remove equalizer tube assembly from motor end of

crankshaft (or eccentric shaft). If shaft turns, preventing

tube assembly from being loosened, block shaft with a

piece of wood.

5. Remove rotor using a jackbolt. Insert a brass plug into

rotor hole to protect end of crankshaft from jackbolt.

Support rotor while it is being removed to prevent stator

damage.

6. Remove connection rod caps from compressors using

connecting rods and crankshafts. Label caps and rods so

they may be reinstalled in same plate on crankshaft.

7. Remove bolts holding counterweights and eccentric strap

side shields to eccentric shaft. Remove eccentric strap

side shields. Remove pump end counterweight through

pump end bearing head opening. Motor end counter-

weight will remain on eccentric shaft until shaft is

removed.

8. Pull eccentric shaft or crankshaft out through pump end

opening. Guide eccentric straps from eccentric shaft

during removal process. Rotate shaft and tap it lightly to

prevent straps from jamming.

9. Remove eccentric straps or connecting rods and pistons

through bottom cover plate opening.

10. Disassemble connecting rods or eccentric straps from

pistons by removing lock ring(s) and piston pins. Remove

oil and compression rings from piston. Keep each piston

assembly together for proper reassembly.

Check all parts for wear and tolerances shown in Table 6.

Check crankshaft (eccentric shaft) oil passages and clean if

clogged.

IMPORTANT: Do not disturb the jam nuts on which the

phase barrier rests.

STRAINER SCREWS & WASHERS

SUCTION STRAINER

MOTOR END COVER

VALVE GASKET

SUCTION SERVICE VALVE

VALVE CAP

SCREW

BARRIER POSITIONING KEY (THIS SIDE IS

ADJACENT TO THE CYLINDER HEAD)

PHASE BARRIER

NO TERMINAL IN

THIS SECTION

TERMINAL NUMBERS ON

THIS SURFACE

TERMINAL

NUT(TYP)

LOCK WASHER

(TYP)

BLACK JAM NUTS

ON TERMINALS 8 & 9;

BRASS JAM NUTS ON

TERMINALS 1, 2 AND 3

CENTRAL SCREW (THREADS

INTO TERMINAL PLATE)

SPACER

(TYP)

Fig. 18 — Motor End Cover Assembly

ACROSS-THE-LINE APPLICATION (5 TERMINALS)

Fig. 19 — Terminal Plate Assembly