Control surface linkage, Throttle linkage – Great Planes Ultra Sport 40 ARF Red - GPMA1005 User Manual

Page 21

Control Surface Linkage

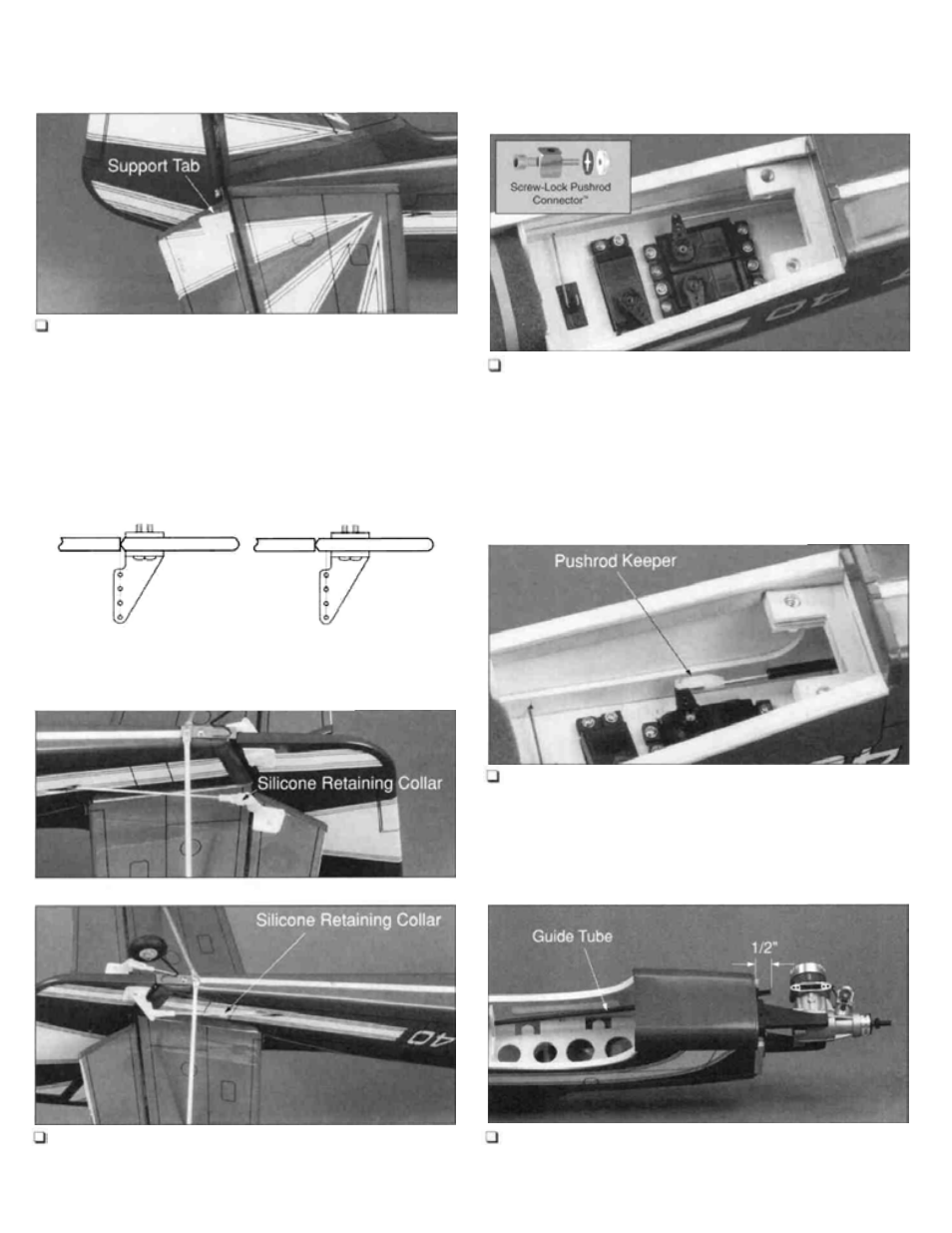

Mount the Control Horn

1. Glue a support tab on each side of the elevator and

rudder in the location where the control horns will be

mounted. NOTE: The support tabs are white in the

photographs for better identification, but clear tabs are

supplied in the kit. Again place the control horns on the

support tabs and mark their location and remove. Drill

each mark with a 3/32" drill bit.

Hinge Line/Control Horn Alignment

indentation in the foam covering, but do not crush the

foam covering. Attach the clevises to the control horns.

Secure the linkages by sliding 1/4" of silicone retaining

collar over the clevis arms.

Connect the Pushrods to the Servos

3. With the rudder and elevator servos centered, mark

the pushrods. Cut the rods 1/4" past the mark and make

an L-bend at the mark. Place the L-bend into the fourth or

outermost hole of the servo arm. It may be

necessary to enlarge the servo arm holes with a 5/64" drill

bit. Note: An alternate technique to make pushrod

connections would be with the use of GP Screw-Lock

Pushrod Connectors for easy adjustments.

Correct Incorrect

Connect the Control Linkages

2. Fasten the control horns to the control surfaces using

Install Pushrod Keeper

4. Install the pushrod keeper over the L-bend and servo

horn, and snap it onto the rod.

Throttle Linkage

Glue the Throttle Guide Tube

1. Note: Read Steps 1-3 before proceeding. There is a

the four 2-56 x 5/8" machine screws and the nylon nut

plates.The support tabs and nut plates can make a slight

throttle pushrod exit hole predrilled in the firewall to

accommodate two cycle engines and four cycle engines if

21