Great Planes Sportster Bipe 40 Kit - GPMA0510 User Manual

Page 21

2.

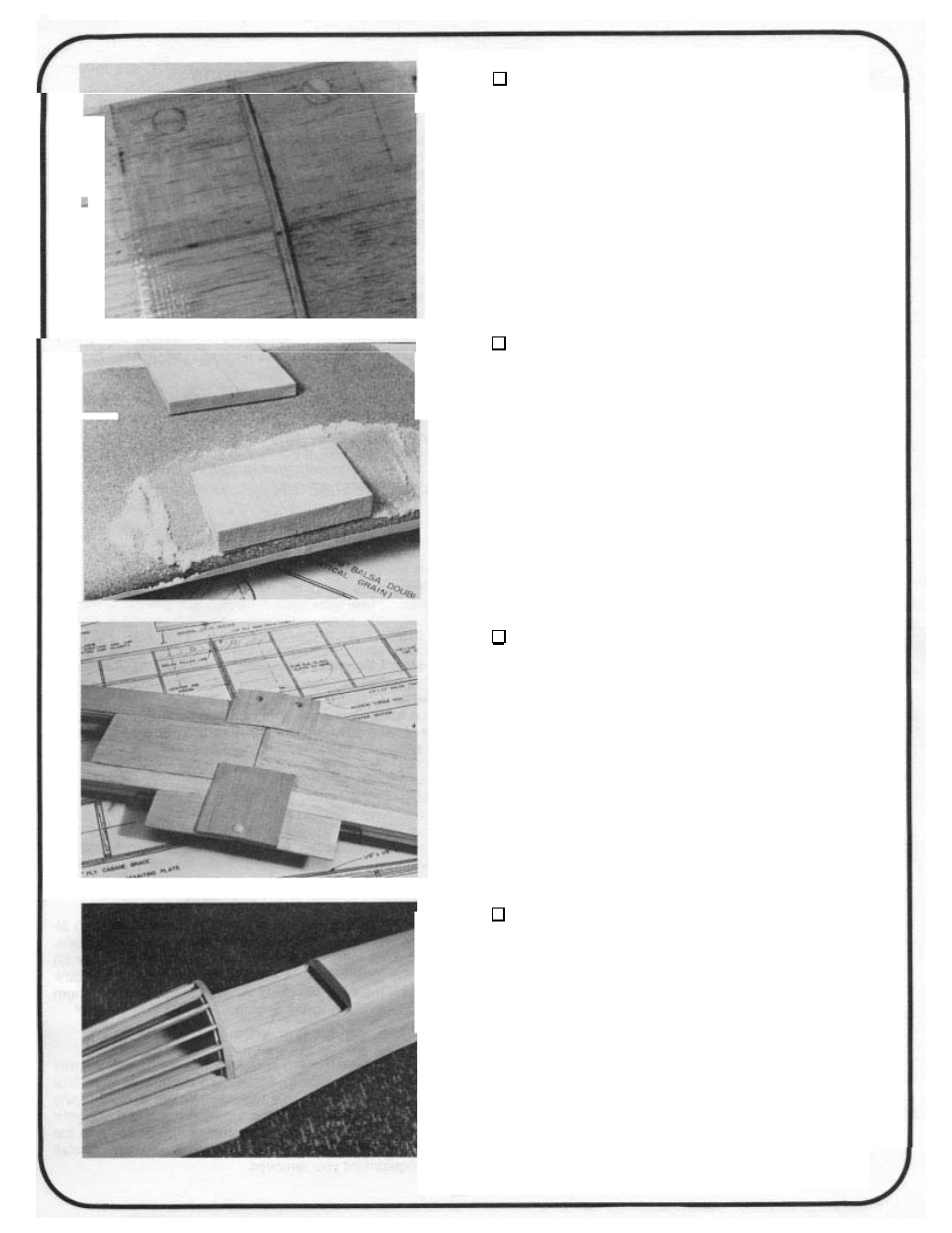

DRILL AND TAP WING BOLT HOLES IN THE WING

AND FUSE

Withe fuse aligned to the work surface and the wing

aligned to the fuse, drill two 11/64 pilot holes through the wing

hold down plates in the leading edge of the wing and one hold

in the trailing edge of the wing. Drill the rear hole at an angle

so

the bolt head will rest flat on the trailing edge. Drill these

pilot holes through the hold downs in the fuselage at the same

time you drill through the wing. Remove the wing. Drill and tap

the holes in the fuselage hold downs for

1/4-20 bolts. Counter-

bore the leading edge holes in the wing

so

that the bolts will

rest flat against the hold downs in the wing.

3.

SAND THE WING FAIRINGS TO SHAPE

Prepare to install the wing fairings by drawing lines

on the bottom of the wing even with the fuselage sides. Cut the

fairings to width. Sand to shape by placing sandpaper on the

wing and working the fairings back and forth.

4.

G L U E THE FAIRINGS

I

N

THE FUSELAGE CONT

PLACE; SAND THEM TO

OUR

Drill holes through the fairings large enough for the

wing bolt heads to pass through. Install the wing bolts and glue

the fairings in place with 5 minute epoxy. Be careful not to get

any epoxy on the wing bolts and not to glue the wing to the

fuselage!When the glue is dry, sand the fairings to the fuselage

contour.

5.

FINISH COCKPIT AREA: FUELPROOF FUSE;

FINAL SAND MODEL

Finish the cockpit area any way you wish. You may

want to add a pilot, paint the cockpit area and/or add an instru-

ment panel. Fuelproof the engine compartment by coating all

the balsa and ply parts with resin or epoxy. Now final sand the

entire model.

21