Dynaflite DYFA2016 User Manual

Page 9

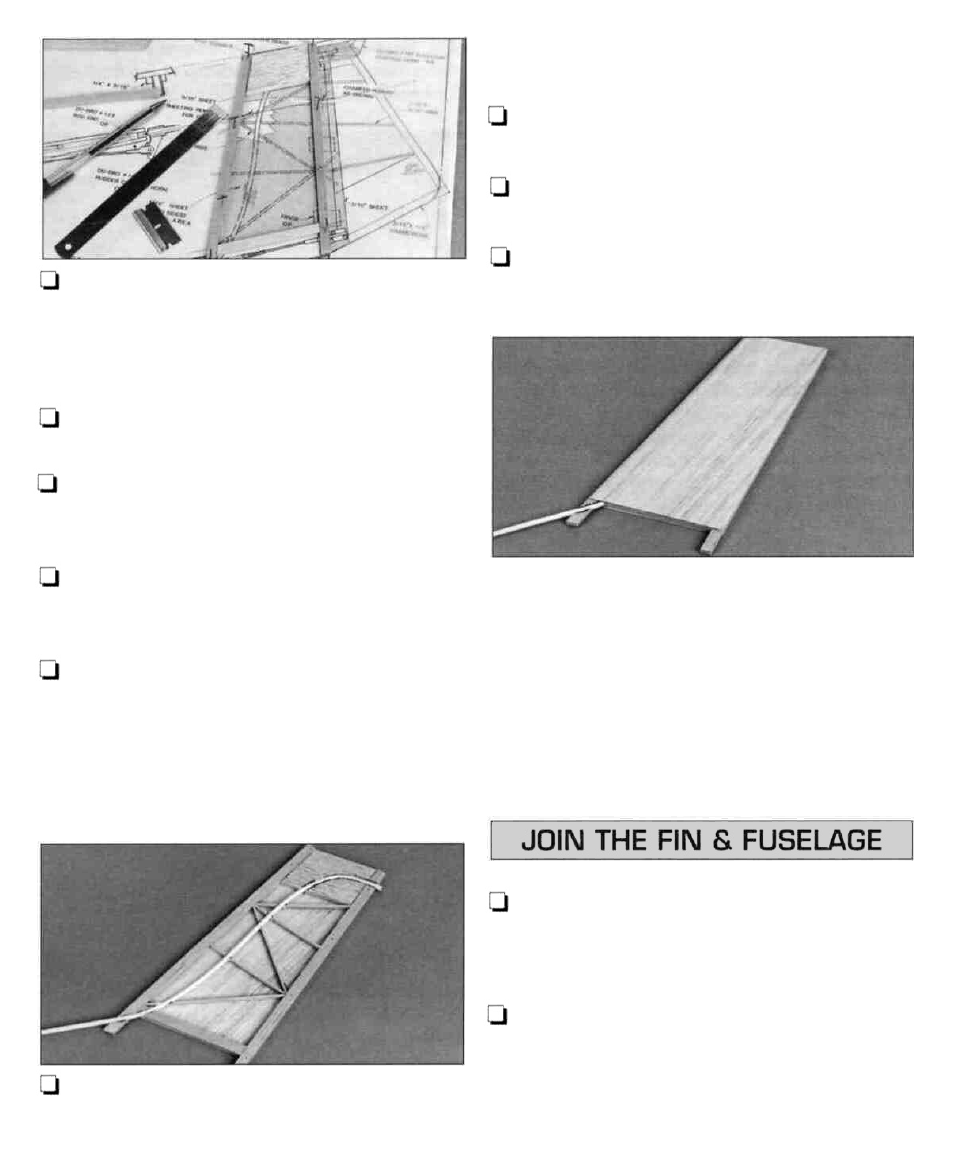

Q 2. Place a sheet of wax paper over the rudder

and fin plan. Build the fin frame from the 3/16" x

1/4" x 24" balsa stick and the 3/16" x 1-3/8" x

24" balsa sheet. Build accurately because the fin

establishes the incidence of the stab.

Q 3. Cut the fin ribs from the 1 /16" x 3/16" x 24"

balsa stick. Glue them in position.

U 4. Remove the fin from your building board and

peel off the wax paper. Carefully sand both sides of

the fin flat.

Q 5. Use a ballpoint pen to mark the left side of the

fin where the elevator pushrod tube (not included,

GPMQ3702) intersects the braces, base and tip.

Q 6. Sheet the right side of the fin with a 1/16" x

3" x 24" balsa sheet. The bottom of the sheet should

align with the bottom of the horizontal 3/16" x 1/4"

"base" portion of the fin. The grain of the sheet

should run parallel to the LE. Use a small piece of

leftover 1/16" balsa sheet for the corner of the fin at

the bottom of the TE.

tip of the fin and in the cross braces. Test fit the tube

to make sure the grooves are deep enough.

U 8. Glue the tube in place with medium CA. Sheet

the left side of the fin the same way as the right.

Q 9. Sand the tip of the fin so it accurately matches

the plan. Round the leading edge.

U 10. If you will be building a functioning rudder,

mark the location of the hinges on the fin and cut the

hinge slots.

A nice little piece of workmanship you have there,

isn't it?

Q 7. Use a MultiPro™ or a hobby knife to cut

grooves for the elevator pushrod guide tube in the

Q 1. Test fit the fin and the guide tube in the

fuselage. If necessary, trim the aft edge of the 1/16"

balsa crutch and cross-grain sheeting so the TE of

the fin aligns with the end of the fuselage.

U 2. Place a piece of wax paper under the back of

the fuse to protect your workbench. Place weights on

top of the fuselage to keep it from moving around

while you work. Wrap masking tape 1/8" above the

bottom of the fin to keep excess epoxy off the fin.

9