Dynaflite DYFA2016 User Manual

Page 27

Q Q 14. Silver solder the clevis to the cable. If you

find it difficult to cut the cable with wire cutters, use a

MultiPro with a cut-off wheel or tin the cable in the

area where it is to be cut with wire cutters.

LJ U 15. Place the control horn on the aileron. Drill

1/16" holes in the aileron for the horn mounting

screws. Remove the aileron and use a pin to poke

holes in the aileron where the control horn will be

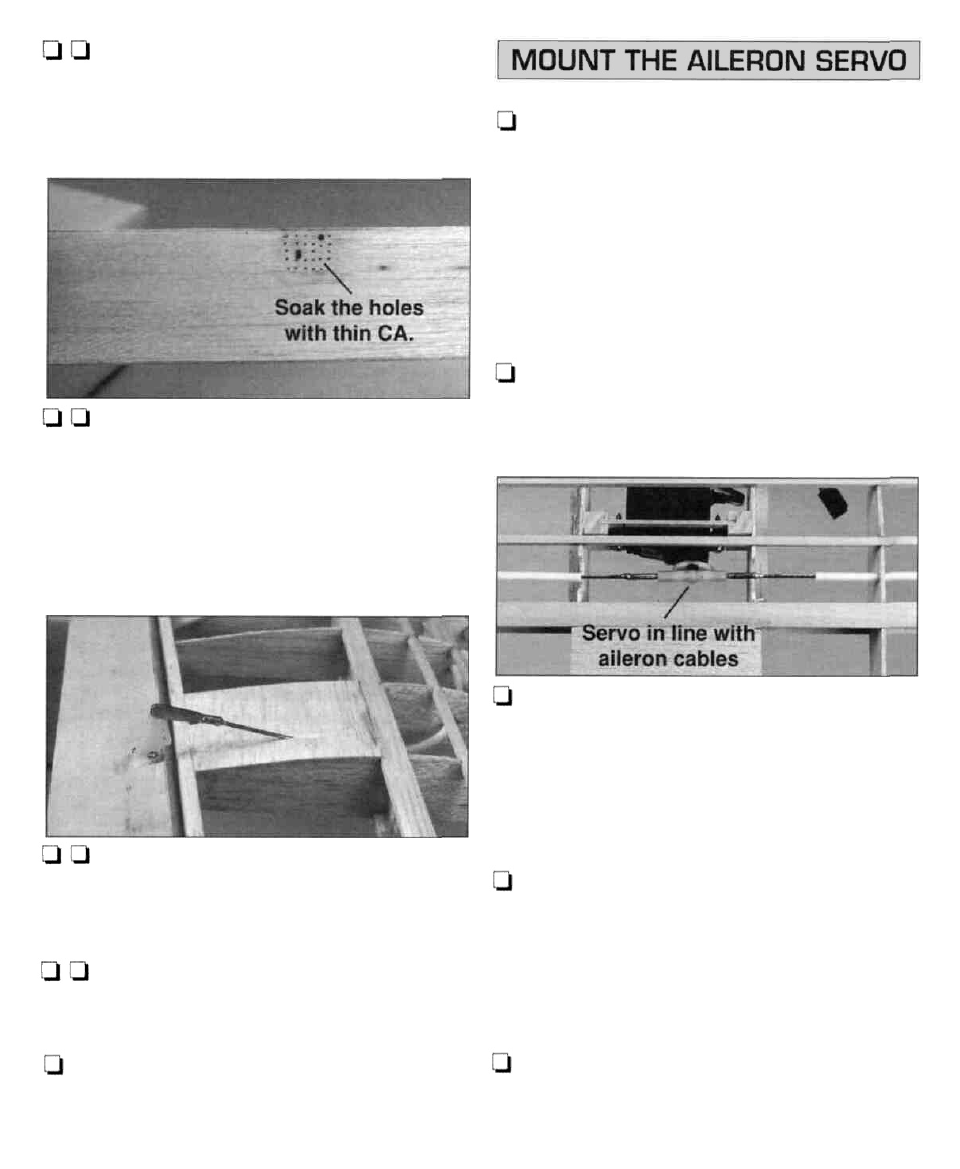

mounted. Saturate the area and the holes for the

horn mounting screws with thin CA. Sand the area

smooth.

Q 1. Connect the aileron servo to your receiver and

turn on your radio. Center the aileron servo with

your transmitter and make sure both ailerons are

neutral. You can still do this without snapping the

ball socket onto the ball by just fitting the ball socket

over the ball, but not snapping it on. It is easiest to

center the aileron servo and ailerons now while the

ball linkage is easily accessible rather than at the

flying field when you will have disconnect the ball

link and remove the servo to make an adjustment.

LJ 2. Connect the ball link to the servo arm or wheel

on your aileron servo with the small nut included with

the ball link. Use thread locking compound or epoxy to

make sure the nut is secure.

U 3. Mix a batch of 30-minute epoxy and glue the

sliders to the #1 ribs. Adjust the sliders so you can

connect the ball socket to the ball on the servo without

bending the aileron cable out of its way. Snap the ball

socket onto the ball. Do not disturb the assembly until

the epoxy is fully cured.

U Q 16. Mount the control horn to the aileron with

two #2 x 1/2" screws. Fit the aileron to the wing

with the hinges and connect the clevis to the control

horn.

Q Q 17. Place the ball socket over the ball link but

do not snap it on. Adjust the ball socket on the

threaded coupler so the aileron is neutral.

U 18. Return to step 1 and connect the other aileron

the same way. Do not snap the ball socket onto the

ball link until instructed to do so.

U 4. If you have to make any adjustments to the

aileron servo or connection, make them now before

you sheet the rest of the center section. You can

easily remove the servo from the compartment after

you sheet the center section by sliding the servo tray

out, but it is easier to access the ball and socket now.

Q 5. Use the remainder of the 1/16" sheeting to

sheet the top center section of the wing forward of

the main spar.

27