Dynaflite DYFA2016 User Manual

Page 18

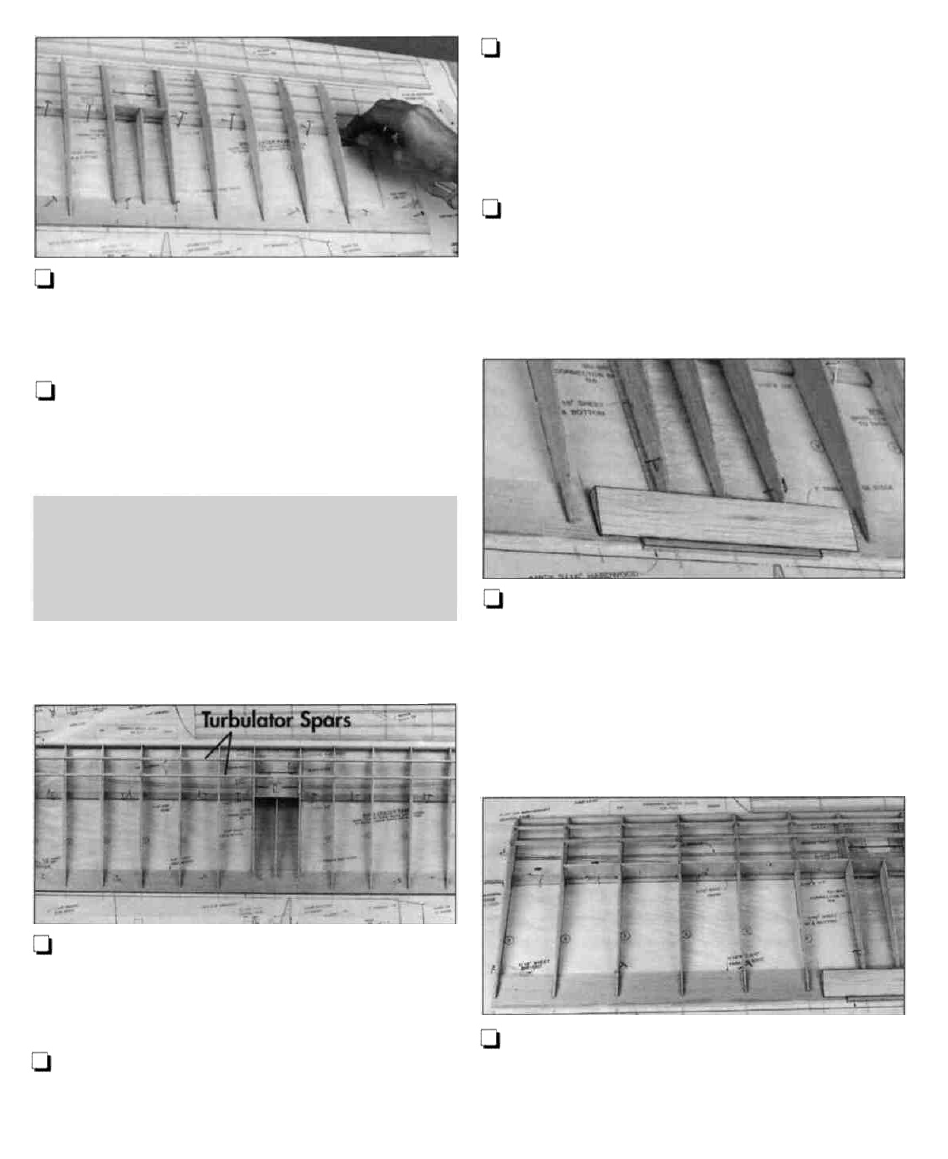

LJ 18. Glue all the #2 ribs to the spar and TE with

medium CA. Use a small 90 degree triangle to keep

the ribs vertical as you apply the glue.

U 22. One at a time, remove the T-pins from the

bottom TE sheeting. Replace them in the rear of the

ribs to hold the aft end of the wing panel to your

building board. This will allow you to

glue the top TE sheeting in position without

interfering with the T-pins.

Q 23. Test fit and final shape the 1 /4" x 6" tapered

balsa trailing edge stock so it is the same height and

has the same taper angle as the "notched section" of

the #2 ribs and there will be enough room to inset

the 1/8" x 3/16" x 4" basswood stick so it will be

even with the TE.

Q 19. Read the Tip that follows. Glue the 5/16" x

30" hardwood leading edge dowel to the ribs with

medium CA.

Tip: Spray the dowel with CA Accelerator before

you position it on the fronts of the ribs. This

way the CA will be sure to cure immediately,

reducing the time you have to hold the dowel

in position.

Q 20. Test fit the 1/8" x 1/8" x 30" basswood

turbulator spars in the notches of the ribs. Glue

them in place with medium or thin CA.

Q 21. Glue a die-cut 1/16" gusset to the bottom

sheeting and outer rib #2 at both ends of the wing

panel.

Q 24. Use medium CA to glue the trailing edge

stock to the end of the #1 ribs and the bottom TE

sheeting. Cut a notch in the bottom TE sheeting for

the 1/8" x 3/16"x 4" basswood stick. Glue it in

position as shown in the photo.

Note: The 1/8" side of the stick should contact the

plan while the 3/16" sides should be vertical.

U 25. Use the 1/16" x 3" balsa sheet to make six

vertical grain shear webs to fit between the #2 ribs of

the left side of the panel. Glue all the shear webs -

except the shear web between the outer set of #2

18