Dynaflite DYFA2016 User Manual

Page 26

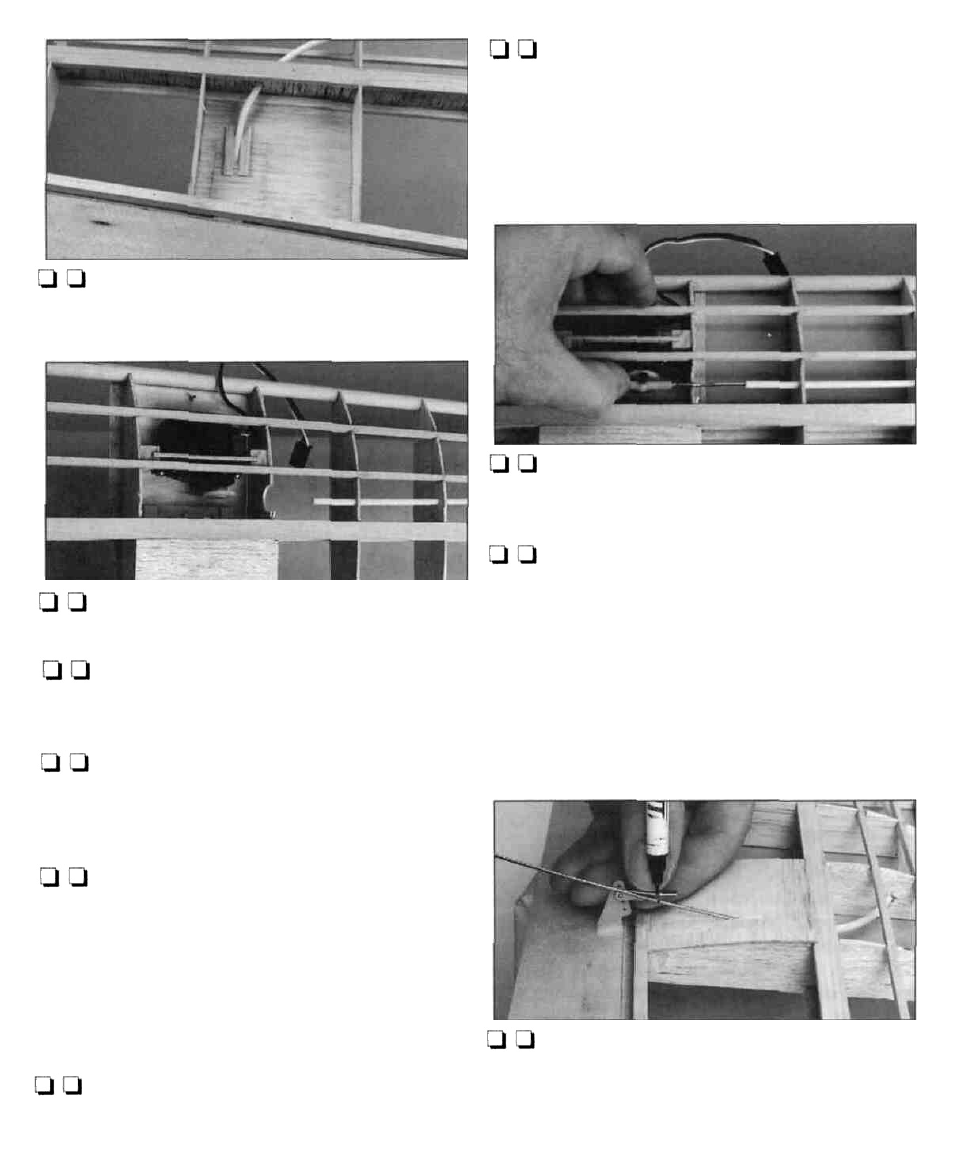

Q Q 4. Glue a 1/16" balsa strip to the inside of

the sheeting on both sides of the slot to keep the

sheeting from splitting.

Q Q 5. Cut the "servo end" of the tube about 3/4"

from rib#1.

Q Q 6. Glue the guide tube in the slot with

microballoons and epoxy. Glue the tube to the ribs

with medium CA.

Q Q 7. After the microballoons and epoxy filler

has fully cured, use your bar sander and 220-grit

sandpaper to sand the guide tube and the filler flush

with the sheeting. See the photo at step 13.

LJ U 8. Remove the aileron servo. Temporarily

install a Great Planes 1/16" Ball Link (not included,

GPMQ3842) onto the servo arm or wheel of your

servo. Reinstall the servo - the sliders should not yet

be glued in place so you can determine the location

of the servo after the exact location of the cable and

ball link socket have been set.

Q Q 10. Cut the threads off a Great Planes 2-56

(1/16") Threaded Coupler (included with the Great

Planes Flexible Cable Pushrod set) so that 5/16" to

3/8" of the threaded portion remains. Silver solder

the threaded coupler to one end of the aileron cable.

Thread the coupler all the way into the dual end ball

link (included with this kit).

Q Q 11. Route the cable through the guide tube.

Align the ball link socket with the ball link on the

servo but do not snap it on.

Q Q 12. Connect a small control horn (included

with this kit) to a Great Planes 2-56 Solder Clevis

(not included, GPMQ3810). Place the control horn

on the aileron as shown on the plan next to the cable

protruding from the wing.

Note: The control horn should be 1/8" aft of the

aileron pivot point (as shown on the plan) for aileron

differential.

Q Q 9. Reinstall the aileron servo with the ball link

on the servo arm.

Q Q 1 3. With the aileron neutral, mark the cable

where to cut it so you leave enough extra to securely

solder it into the clevis. Remove the clevis from the

control horn. Cut the cable at the mark you made.

26