Dynaflite DYFA2016 User Manual

Page 25

U LJ 2. Remove the clamps and separate the panels.

Lay a piece of wax paper on your building table. Mix

a batch of 30-minute epoxy. Coat the joining surfaces

with 30-minute epoxy. Join the inner wing panels with

the dihedral brace. Refrain from using excess epoxy

so the shear webs will fit later. Place the wing on your

building table. Immediately proceed to the next step.

o o 3. Place a weight on the center section to hold it

down. Prop up the outer panel so the tip is 3/4"

above your table. Clamp the wing halves together

the same as you did in the first step.

Q Q 4. Wipe away excess epoxy before it cures. Do

not disturb the wing until the epoxy is fully cured.

Q 5. Return to step 1 and join the left panel to the

center section the same way.

U 3. Make sure the holes in the joining #2 ribs of

both wing panels align so you can route the outer

aileron cable guide tube. If the holes do not align,

open them up with a hobby knife.

Note: These instructions are written for connecting

the ailerons with Great Planes* Flexible Cable

Pushrods, though Sullivan

Gold-N-Push Rods are shown on the plan. If you

decide to use the Sullivan Gold-N-Rods, the

instructions are the same for installing the guide

tubes, but connect the clevises and ball links as

shown on the plan.

U LJ 1. Roughen the outside of a Great Planes 36"

Flexible Cable Pushrod guide tube (not included,

GPMQ3702) with coarse sandpaper so the glue will

stick. Route the guide tube through the holes in the

ribs of the right wing panel.

U U 2. Use a #11 blade to cut an approximately

1/2" diameter circular notch in rib #1 where the

guide tube passes. This will allow the solder

connector to clear the rib without interfering. See the

photo at step 5.

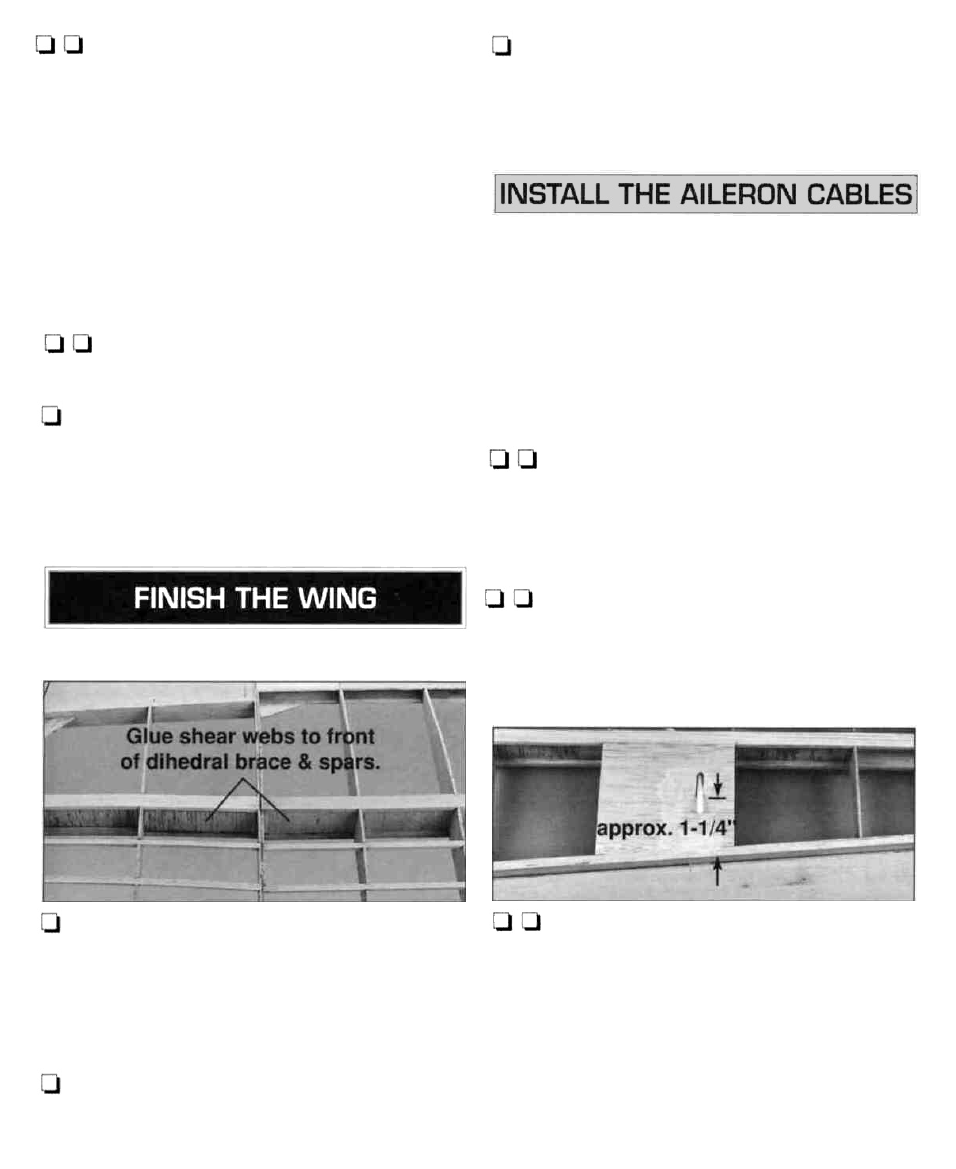

U 1. Use epoxy to glue the four shear webs you cut

earlier to the plywood dihedral braces and spars on

both sides of the joining wing panels. It does not

matter whether you glue the shear webs to the front

or back of the shear webs, but do it the same way

on all four webs for symmetry.

Q 2. Sand-off glue bumps and blend the spars and

LE's and TE's of the joining wing panels.

1-11- 3. Cut a 1/2" long slot in the sheeting

between ribs #6 and #7 where the guide tube will

pass through. Be careful not to make the slot too far

aft or the clevis will interfere with the guide tube and

limit aileron throw. The aft end of the slot should be

approximately 1-1/4" from the aft edge of the aft

spar. Route the guide tube through the slot and cut

the tube so it protrudes from the sheeting (on top of

the wing) about 3/8".

25