Drill and install the propeller – DLE 30 User Manual

Page 9

9

8. Cut all necessary clearance, carburetor adjustment, cooling, and

exhaust holes in the cowl.

9. Make sure the cowl is secured to the airplane and that the spinner

back plate to cowl clearance is at least 1/8” [3.2mm].

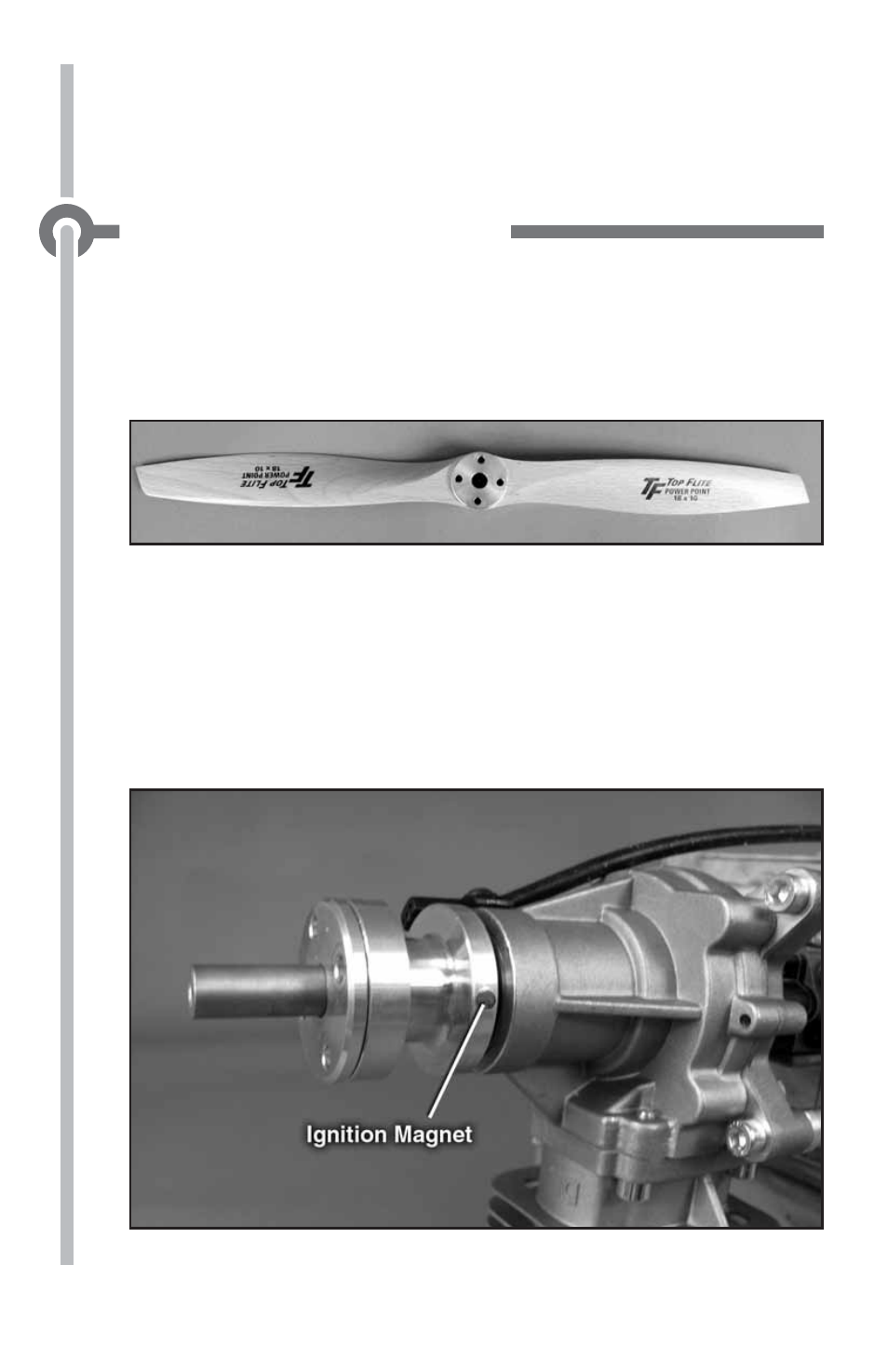

Drill and Install the Propeller

The easiest way to drill the propeller to fi t the hub is to use a drill guide.

If you do not have a drill guide, you can use the following method to

drill your propeller. Most propellers within the recommended size

range have a 0.393" [10mm] center hole pre-drilled. If your propeller

has this predrilled hole, move on to step 3. If not, start with step 1.

1. Remove the cowling from the aircraft. Use the included propeller

washer to mark the centering hole on the propeller

2. Once the location is established, use a drill press with a 13/32

(.406/10.31mm) drill bit. In order to achieve a clean hole opening on

both sides of the propeller, drill only half way through the propeller

with the 13/32 (.406/10.31mm) drill bit. Then fl ip the propeller over

and drill completely through the hole.

3. Next, set the engine at the top of the compression stroke. Note

the position of the ignition magnet with engine inverted.