Jumper settings – Digilent 410-259P User Manual

Page 2

PmodDHB1™ Reference Manual

®

www.digilentinc.com

www.digilentinc.com

Copyright Digilent, Inc.

page 2 of 3

The quadrature encoder signals are a pair of

square waves whose frequency is proportional

to motor rotation speed and with the pulses 90°

out of phase. You can determine the motor

speed with the frequency and motor rotation

direction by the phase relationship between the

two signals.

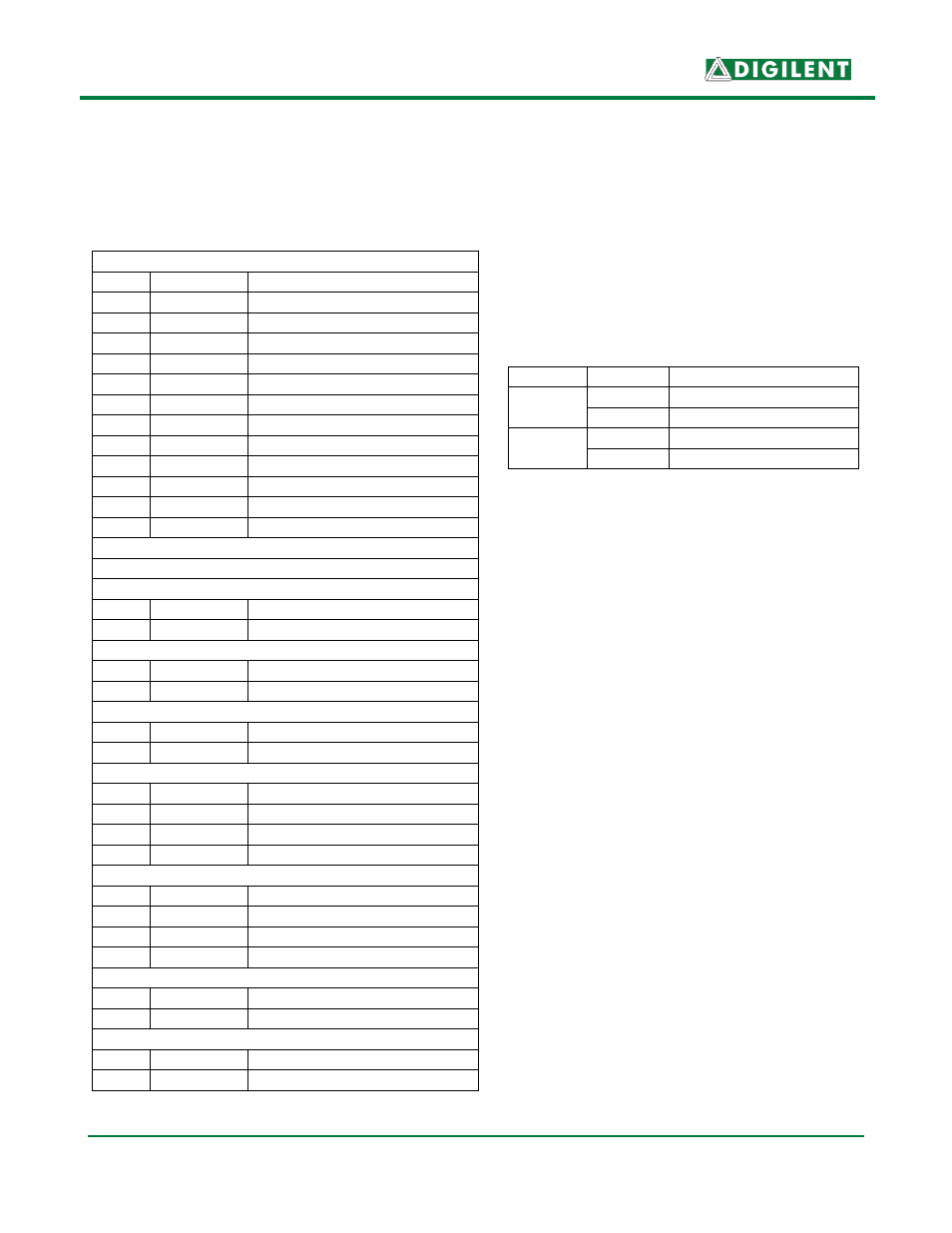

Jumper Settings

Jumpers JP1 and JP2 allow both h-bridge

outputs to be run from the same enable and

direction pins. This allows the two bridge

outputs to be operated in parallel to drive a

single motor with twice the current. Refer to

Table 3 for available settings.

Jumper Setting

Description

JP1

1

Motor 2 Uses EN1

3

Motor 2 Uses EN2

JP2

1

Motor 2 Uses DIR1

3

Motor 2 Uses DIR2

Table 3: Set Jumper Description

Pulse Width Modulation and Motor

Speed Control

Operators can control motor speed by varying

the input voltage to a circuit. However, you

can only apply a logic high or logic low signal

to the motor in a digital circuit. There are only

two ways to control a dc motor digitally. Either

use a variable resistance circuit to control the

motor voltage, or pulse the power to the motor.

Since variable resistance circuitry is expensive,

complicated, and energy inefficient because of

heat loss, Digilent recommends controlling

motor speed through pulse width modulation

(PWM).

Pulse width modulation is a digital method of

transmitting an analog signal. Even though

PWM is not a clean source of DC output

voltage, it controls motors well.

Figures 1 through 3 illustrate a PWM system

with an input frequency of 2KHz. You control

the motor speed by adjusting the time each

wave remains at peak output power. Figure 1

demonstrates a 10% “duty cycle,” where the

signal is logic high for only 1/10 of a

wavelength. This 10% positive peak is equal to

10% of the total 3.3V input, or 0.33V. (See

Connector J1 – H-Bridge Interfaces

Pin

Signal

Description

1

EN1

Motor 1 Enable

2

DIR1

Motor 1 Direction

3

S1A

Motor 1 Sensor A Feedback

4

S1B

Motor 1 Sensor B Feedback

5

GND

Power Supply Ground

6

VCC

Power Supply (3.3V)

7

EN2

Motor 2 Enable

8

DIR2

Motor 2 Direction

9

S2A

Motor 2 Sensor A Feedback

10

S2B

Motor 2 Sensor B Feedback

11

GND

Power Supply Ground

12

VCC

Power Supply (3.3V)

Connector J2- M1 JST 6-Pin Motor Connector

Connector J3- M1 JST 6-Pin Motor Connector

Connector J4- VM

1

VM

Motor Power

2

GND

Power Supply Ground

Connector J5- M1 Power

1

M1+

Motor 1 Positive Supply

2

M1-

Motor 1 Negative Supply

Connector J6- M2 Power

1

M2+

Motor 2 Positive Supply

2

M2-

Motor 2 Negative Supply

Connector J7- M1 Feedback

1

SA1-IN

Sensor A From Motor 1

2

SB1-IN

Sensor B From Motor 1

3

GND

Power Supply Ground

4

VCC

Power Supply (3.3V)

Connector J8- M2 Feedback

1

SA2-IN

Sensor A From Motor 2

2

SB2-IN

Sensor B From Motor 2

3

GND

Power Supply Ground

4

VCC

Power Supply (3.3V)

Connector J9- Fault

1

NFAULT

Overcurrent Condition

2

GND

Power Supply Ground

Connector J10- Sleep

1

NSLEEP

Puts device into sleep state

2

GND

Power Supply Ground

Table 2: Connector Descriptions