Crosman 1701P User Manual

Page 7

7

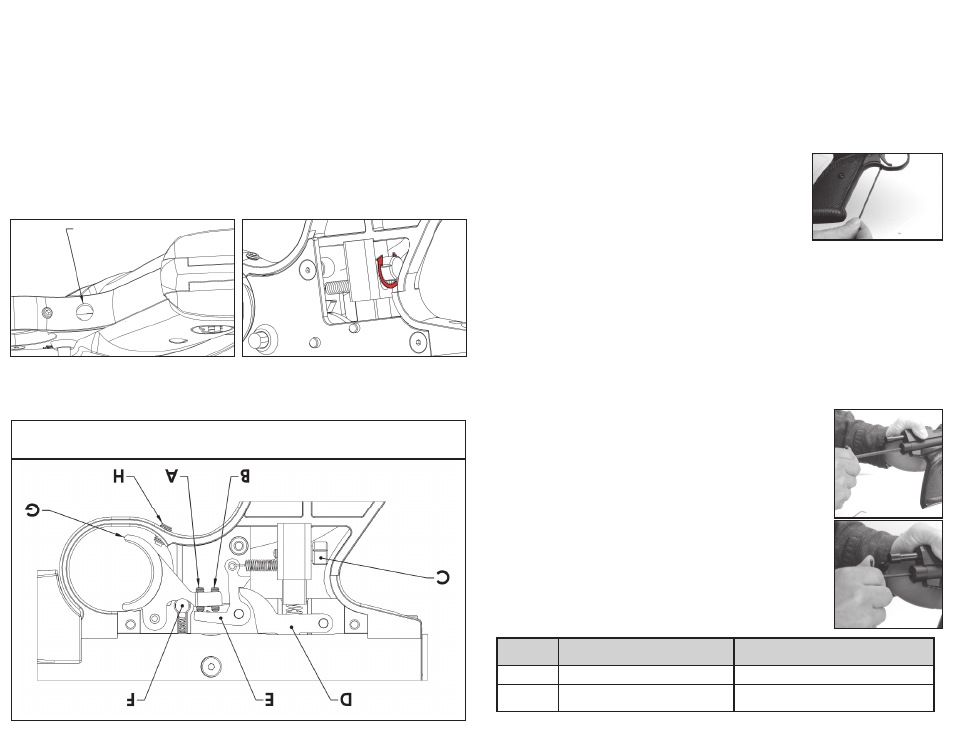

Fig 9

A. AJUST

ADOR DE LA PRIMERA ETAP

A

B. AJUST

ADOR DE LA SEGUNDA ETAP

A

C. AJUST

ADOR

DEL PESO DEL GATILLO

D. FIADOR

E. ESLABÓN

F . SEGURO

G. GATILLO

H. TORNILLO DE

EXCESO DE RECORRIDO DEL GATILLO

Resistencia del gatillo

Busque el tornillo ajustador del peso del gatillo C (Fig. 8). V

isto desde el punto de ventaja de tiro, gir

e el

tornillo en el sentido de las agujas del r

eloj (Fig. 9A) para aumentar la fuerza de resistencia del gatillo y en

sentido contrario a las agujas del reloj para r

educir la fuerza de resistencia del gatillo. Este ajuste no afecta el

enganche del fi ador

.

Fig 10A

Orifi

cio De Acceso

Fig 10B

B. Ajuste del gatillo de dos etapas

• To

rnillos ajustador

es de etapa del gatillo: Ubique el orifi cio de acceso de los tor

nillos de ajuste de etapas

debajo del bastidor de la cacha (Fig. 9B). Con una llave Allen de 0,050” para ajustar los tornillos (A) y (B),

es posible cambiar la posición y longitud de la primera y segunda etapa del movimiento del gatillo. Estos

ajustes podrían afectar el enganche del fi ador y

, por lo tanto, podrían hacer que la pistola se dispar

e al

dejarla caer o sacudirla.

• El tor

nillo (A) cambia la primera etapa. Girar el tornillo (A) en el sentido de las agujas del r

eloj aumentará

la longitud de la primera etapa y disminuirá el enganche del fi ador

. Girarlo en sentido contrario al de las

agujas del reloj disminuirá la longitud de la primera etapa y aumentará el enganche del

fi ador

.

• El tor

nillo (B) cambia la segunda etapa. Girar el tornillo (B) en el sentido de agujas del r

eloj hará que

la segunda etapa ocurra más rápido; girarlo en sentido contrario al de las agujas del reloj hará que la

segunda etapa ocurra después.

• El ajuste de los tor

nillos (A) y (B) debe hacerse en conjunta armonía, ya que trabajan unidos para crear el

perfi l del gatillo. Empiece lentamente para entender lo que hace cada ajuste y su r

elación con el otro.

• Después de ajustar el gatillo, siempr

e verifi que que el gatillo y el segur

o estén funcionando correctamente.

Si no está seguro de que el gatillo o el segur

o funcionan correctamente, lleve su arma a un armer

o experi-

mentado.

• Vuelva a colocar la cacha y el tor

nillo de la cacha.

7

• For creating a single stage trigger, adjust screw (A) clockwise until the desired Sear engagement is

attained. Adjusting screw (A) in this manner will eliminate engagement of screw (B) and will yield the

lightest possible single stage trigger pull. Screw (B) can also be utilized to create single stage trigger by

turning in clockwise until the desired Sear engagement is attained. It is advised to also turn Screw (A) out

counter-clockwise a few turns to ensure it is no longer engaged at any point. Which screw is utilized to

create the single stage trigger depends on the preference of the individual.

• After adjusting your trigger, always check that the trigger and safety are functioning properly. If you are not

sure if the trigger or safety is operating properly, take your gun to an experienced gunsmith.

• Replace the Grip and Grip screw.

D. Maintaining the Marauder Pistol Trigger

• The Marauder pistol trigger is assembled with a moly graphite EP grease that should last for years. In the

event your trigger becomes contaminated with debris and is not functioning properly, contact a qualifi ed

gunsmith to examine for repair or necessary maintenance.

E. Adjusting the Trigger Over-travel

• To ensure crisp, consistent action of the trigger, a set screw has been

incorporated into the trigger guard to allow each shooter to set the

trigger over-travel to their preference. Removing the screw will give the

most over travel, tightening the screw all the way in will stop the trigger.

Shooters will fi nd their preference somewhere in between.

• Make sure the air pistol is unloaded (section 4B) and de-gassed (section 3D)

• Turn the set screw (H) as shown in Figure 8, all the way in with a hex wrench.

(not included)

• Cock the bolt by pushing the bolt handle up and pulling it all the way

back. Close the bolt and push the bolt handle down to lock.

• Point the air pistol in a SAFE DIRECTION, take “OFF SAFE” (section 2B) and pull the trigger. If the pistol

does not fi re, turn the set screw counter clockwise in ½ turn increments until it fi res.

IMPORTANT! Turn an additional ½ turn counter clockwise. This is important to ensure proper operation of

the trigger.

• Put the air pistol “ON SAFE”.

10. Adjusting for Various Fill Pressures and Velocities

• Proper adjustment of the 1701P requires use of a chronograph.

• The 1701P has been factory set for a fi ll pressure of

2900 psi and velocity of approximately 450 fps.

These settings will suit most target uses and will yield a long usable shot string. If you, as the owner, wish

to alter the factory settings you should do so only after reading the following instructions carefully.

• The 1701P is designed to be tuned to work at various fi ll pressures from 2500 psi (172 bar) up to 3000

psi (207 bar). This is done by adjustment of the hammer spring preload and hammer stroke length. In

either case the adjustment changes the amount of energy the hammer generates when striking the valve.

Higher fi ll pressures require more hammer energy while lower fi ll pressures require less hammer energy.

Higher fi ll pressures will typically yield more usable shots from a given charge. It is advised to always

record your settings when tuning your airgun.

• The 1701P can be adjusted to achieve various velocities using the same procedures described herein.

This would mainly be done to compensate for heavier pellets IE 10.5 grain vs. 7.9 grain.

A. Hammer Spring Preload Adjuster

The hammer spring preload adjuster may be accessed through the rear plug on

the reservoir tube with a 3/16” Allen wrench as shown in fi gure 11. To increase

hammer energy turn the preload adjuster clockwise up to 7 revolutions. This

would be the case when starting from all the way back counterclockwise.

NOTE: More revolutions will simply cause the adjuster to spin but will not yield any

higher force. Increasing the preload will be required to facilitate use of higher fi ll

pressure.

To lessen hammer energy turn the adjuster counterclockwise. It is advised to

always record your settings when tuning your airgun.

B. Stroke Adjustment

The striker can be accessed through the hammer spring preload adjuster using a

1/8” Allen wrench (fi g 12). Turning the striker clockwise will shorten the hammer

stroke and turning counter clockwise will lengthen the stroke. A long stroke length

will yield higher hammer energy while a short stroke length will yield lower hammer

energy. The striker can be adjusted inward by up to 12 revolutions though this

many turns would never be necessary.

• A starting point for low fi ll pressures would start with a low hammer spring

preload tension and a shorter hammer stroke.

• A starting point for higher fi ll pressures will require more hammer spring

preload tension and a longer hammer stroke. Refer to the chart below for sug-

gested combinations of these adjustments based on fi ll pressure.

Fill

Pressure

Hammer Spring Preload

Hammer Stroke

Higher

Increase, turn adjuster in (Clockwise)

Increase. Turn Striker out (Counter Clockwise)

Lower

Decrease, turn Adjuster out (Counter

Clockwise)

Decrease. Turn Striker in (Clockwise)

Fig 11

Fig. 12

Fig. 13

Fig. 13