Crosman 1701P User Manual

Page 5

5

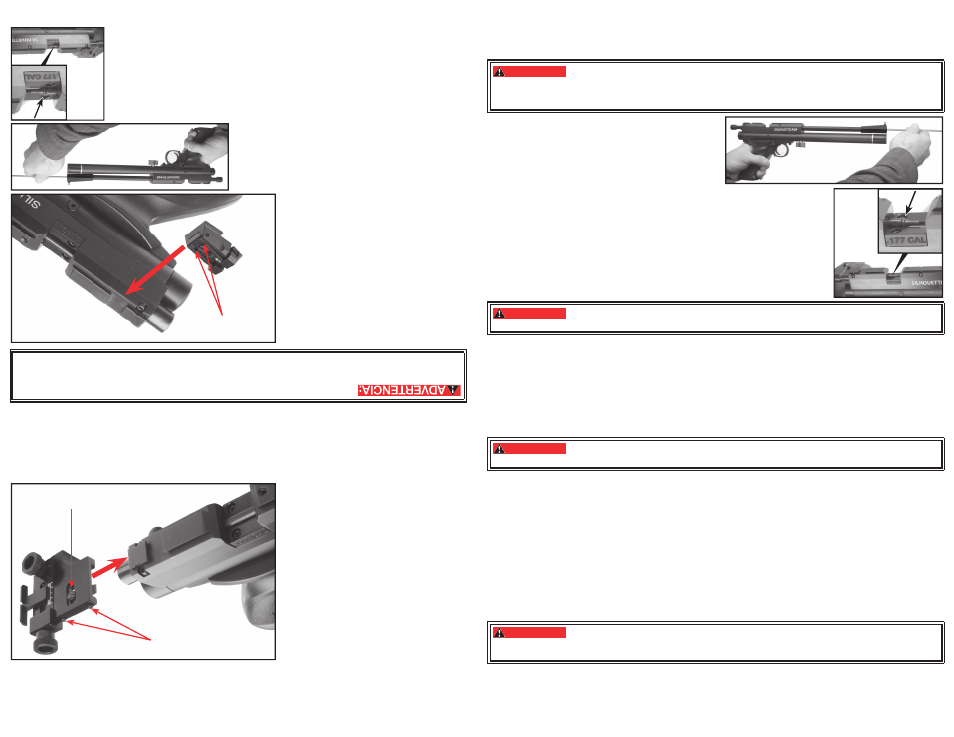

a. Riel cola de milano de 3/8”(mira Williams

®

)

ºA

fl oje el tor

nillos de fi jación en el lado der

echo de la mira hasta que el interior del tornillo quede alineado

con el interior de la mira. Fig. 6A

ºA

fl oje el tor

nillo en la parte superior de la mira apenas lo sufi ciente como para deslizar por completo el

tornillo (y la montura acoplada) hacia la der

echa.

ºDeslice la mira en la parte posterior

del arma, de modo que la muesca u

óptica quede hacia la parte posterior

del arma.

ºApriete bien el tor

nillo superior para

evitar inclinar el riel al ajustar los dos

tornillos de

fi jación.

ºApriete los dos tor

nillos de fi jación.

ºApriete el tor

nillo superior.

ºSiga el pr

ocedimiento para ajustar el

arma según las instrucciones de la

mira.

b.Ranura tipo cola de milano más

delgada (mira LPA

®

)

ºA

fl oje los dos tor

nillos hexagonales

de la mira (observe los dos agujeros

pequeños en la parte superior de la

mira). Fig 6B

ºDeslice la mira hacia la cola de milano

más delgada y el centro del arma.

ºAjuste los dos tor

nillos hexagonales.

ºSiga el pr

ocedimiento para ajustar el arma según las instrucciones de la mira.

6. Extracción de un perdigón atascado

Por lo general, un perdigón se atasca cuando se intenta disparar la pistola de air

e a una presión muy baja.

Antes de disparar la pistola de aire, asegúr

ese de que haya presión su

fi ciente para una operación adecuada.

Para ello, verifi que que la aguja del manómetr

o señale el área que se encuentra entr

e 1000 y 3000 psi.

Para r

ealizar este procedimiento coloque una baqueta de limpieza en el cañón

de la pistola de aire car

gada. Es de suma importancia que mientras realice este pr

ocedimiento el seguro

de la pistola de aire se encuentr

e activado (“ON SAFE”), que el cerrojo permanezca abierto y que su

dedo se mantenga alejado del gatillo. De lo contrario, podría causar lesiones graves e incluso la muerte.

• Apunte la pistola en una DIRECCIÓN

SEGURA.

• Active el segur

o de la pistola de aire

(“ON SAFE”) (consultar la sección 2A).

• Abra el cerr

ojo tirando de la palanca del

cerrojo hacia arriba y completamente

hacia atrás.

• Con el cerr

ojo en la posición más

retrasada, intr

oduzca una baqueta

del tamaño adecuado en el cañón

(empezando por la boca). (Fig. 6) Es

posible que se dañe el cañón si no usa

una baqueta de limpieza del tamaño

adecuado.

Nota: El cerr

ojo debe estar montado y abi-

erto para que el perdigón atascado despeje

la recámara al ser expulsado por la baqueta.

• Con la baqueta, empuje el per

digón hacia el puerto

de carga de perdigones (fr

ente del cerrojo), quite

y descarte el perdigón. No vuelva a usar dicho

perdigón.

• Apunte la pistola en una DIRECCIÓN SEGURA.

Cierre, desactive el segur

o (“OFF SAFE”) y dispare.

• Active el segur

o de la pistola de aire (“ON SAFE”) (consultar la sección 2A).

• Si no puede desatascar la pistola de air

e con este procedimiento, no empr

enda

ninguna otra acción. Crosman Corporation o una Estación de Servicio Autorizada

lo ayudará a desatascar su pistola de aire. (Sin costo alguno durante el período

de garantía)

Fig. 6A

tornillos

hexagonales

tornillos

Fig. 6B

tornillos

hexagonales

Fig

. 7

Fig. 7

Fig

. 8

Fig. 8

5

6. Removing a Jammed Pellet

A jammed pellet is usually the result of trying to fi re the airgun when the pressure is too low. Before fi ring the

airgun make certain there is suffi cient pressure for proper operation, by making sure the gauge needle is

pointing to the area between 1000 and 3000 psi.

WARNING:

In this procedure you will put a cleaning rod down the barrel of a charged airgun. It is

extremely important that while you are doing this the airgun be “ON SAFE”, the bolt remains in open

position and that your fi nger be kept away from the trigger. Failure to follow this warning may result in

serious injury or death.

• Point the airgun in a SAFE DIRECTION.

• Put the airgun “ON SAFE” (see section 2A.)

• Open the bolt by pushing the bolt handle up and

pulling it all the way back.

• With the bolt in the rearward position insert a

ramrod of the proper size into the barrel (start at the

muzzle). (fi g. 6) The barrel could be damaged if the

proper sized cleaning rod is not used.

Note: The bolt must be cocked and open for the jammed pellet to clear the

breech when it is pushed out by the ram rod.

• Using the ramrod push the pellet into the pellet loading port (forward of the

bolt), remove and discard the pellet. Do not reuse that pellet.

• Point the airgun in a SAFE DIRECTION. Close the action take “OFF SAFE” and fi re.

• Put the airgun “ON SAFE” (see section 2A.)

• If you are not able to unjam your airgun by following this procedure, take no

further action. Crosman Corporation or an Authorized Service Station will

unjam your airgun. (no cost during the warranty period)

7. Maintaining Your Airgun

WARNING:

Use of petroleum-based lubricants in the pressure reservoir could result in an explo-

sion resulting in personal injury.

• Keep all petroleum-based lubricants away from the fi ll nipple. They MUST NOT be introduced into the high

pressure reservoir.

• Apply Crosman silicone chamber oil (part number RMCOIL) on the bolt o-ring every 3 months or 500

shots (fi g. 7)

• Apply a moly graphite EP (Extreme Pressure) grease to the sliding bolt mechanism every 3 months or 500 shots.

DO NOT MODIFY OR ALTER YOUR AIRGUN. Attempts to modify the airgun in any way inconsistent with

this manual may make your airgun unsafe to use, cause serious injury or death, and will void the warranty.

If you drop your airgun, visually check to see that it works properly before you use it again. If anything seems

changed, like a shorter or weaker trigger pull, this may mean worn out or broken parts. Call Crosman cus-

tomer service for assistance before using your airgun again.

WARNING:

Do not attempt to repair the airgun or to disassemble to correct an over fi ll or valve

lock. Parts can fl y from the airgun at dangerous speeds when it is disassembled while pressurized.

8. Changing the Bolt Direction

The bolt direction on your 1701P Silhouette PCP pistol is capable of being changed to the opposite hand. The

1701P is factory assembled to accommodate a right handed Silhouette shooter by having the bolt pointing

left. This allows cocking of the bolt and loading pellets with the left hand while maintaining the grip hold with

the right. Disassembly of the Breech and Barrel assembly from the Reservoir Tube assembly is required to ac-

cess the parts contained within the Breech that facilitate the change to the opposite hand. Crosman Corpora-

tion recommends the use of an approved Service Station to perform the change. An approved Service Station

may be found through www.crosman.com or by calling Customer Service at 1-800-724-7486.

9. Advanced Tuning Techniques

A. Adjusting the Trigger (Overview)

The Marauder pistol trigger assembly can be adjusted to achieve a variety of trigger profi les. It has been fac-

tory set for a two stage profi le but can also be changed to a single stage. Unless you are experienced in mak-

ing such adjustments, Crosman recommends that adjustments to factory settings be made only by a qualifi ed

gunsmith after reading all instructions.

WARNING:

Adjusting the trigger assembly can result in a light trigger pull and or decreased sear

engagement that could make the gun more susceptible to discharge when dropped or jarred WITH OR

WITHOUT THE SAFETY ENGAGED. Make only the adjustments identifi ed in this manual.

NOTE: These adjustment features are for advanced shooters. Most shooters can use the factory settings and

should not need to make modifi cations.

• Put the air pistol“ON SAFE”, remove the clip and keep the air pistol pointed in a SAFE DIRECTION.

• Depressurize the air pistol (see section 3D).

• Remove the right side Grip Screw and Grip using a straight blade screw driver.

Fig. 7

Fig. 7

Fig. 8

Fig. 8