Crosman MAR177 User Manual

Page 6

6

8. Unloading and Uncocking the Airgun

a. Unloading – Removing the Rotary magazine

1.

Cock the bolt fully rearward in order to remove the rotary magazine.

2.

Put the airgun “ON SAFE” (see firearm owner’s manual) and point in a

SAFE DIRECTION.

3.

Push the rotary magazine out of the receiver from the left side.

4.

With the airgun pointed in a safe direction close bolt and discharge

5.

The airgun is now ready for storage or removal from firearm lower.

9. Aiming and Firing Safely

• Always point your airgun in a SAFE DIRECTION.

• Follow the instructions for filling the airgun (section 5A or 5B) and loading

pellets (sections 7A and 7B).

• You and others with you should always wear shooting glasses to protect

your eyes.

• Do not shoot at hard surfaces or at the surface of water. The pellet

may bounce off or ricochet and hit someone or something you had

not intended to hit.

• Always choose your target carefully and be sure to have a safe

backstop.

• Your airgun is designed for target shooting and is suited for both

indoor and outdoor use. Always remember to place your target care-

fully. THINK about what you will hit if you miss the target.

• Before firing the airgun make certain there is sufficient pressure for

proper operation. The gauge needle should be pointing to the area

between 1000 PSI and 2900 PSI (200Bar) on the gauge.

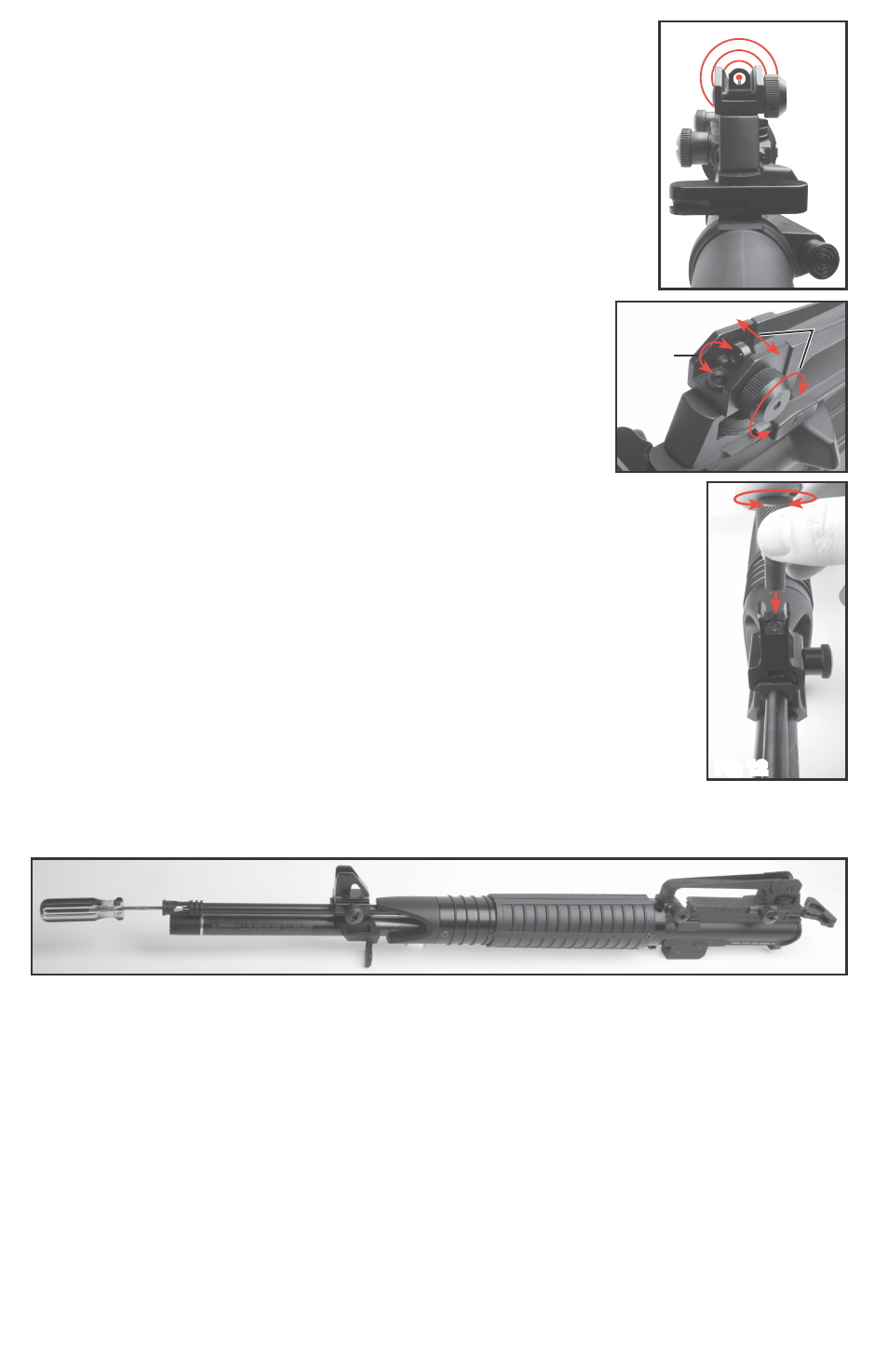

a. Sight Adjustment

1.

This airgun comes with an adjustable rear sight for windage (left or right move-

ment) and elevation (Fig. 11A). You can adjust the rear sight right or left by

turning the vertical knob attached to the dual aperture to the desired direction.

The horizontal knob is for elevation adjustment. Use large aperture for short

range and the small aperture for normal range. (Fig. 11B) To change aperture

size, simply push the desired size to the top.

2.

The front sight is adjustable for elevation. To adjust elevation, depress detent

and rotate post (Fig. 12)

10. Removing a Jammed Pellet

A jammed pellet is usually the result of trying to fire the airgun when the pressure is too

low. Before firing the airgun make certain there is sufficient pressure for proper

operation, by making sure the gauge needle is pointing to the area between 1000 PSI

and 2900 psi (200 bar). If the gun becomes jammed, depressurize the gun follow the

Hex Wrench Method: (section 6B)

a. Make certain the airgun is not in the cocked position by:

1.

Pointing the airgun in a SAFE DIRECTION.

2.

Removing the rotary magazine.

3.

Closing the airgun bolt by sliding forward and latching.

4.

Pulling the trigger.

5.

Depressurize (see section 6a, 6b)

6.

Point the airgun in a SAFE DIRECTION.

7.

Put the airgun “ON SAFE” (see firearm owner’s manual).

8.

Open the bolt by pushing the bolt handle up and pulling it all the way back until you hear two clicks.

9.

With the bolt in the rearward position insert a ramrod of the proper size into the barrel (start at the

muzzle) (Fig. 13). The barrel could be damaged if the proper sized cleaning rod is not used.

NOTE: The bolt must be cocked and open for the jammed pellet to clear the breech when it is pushed

out by the ramrod.

10.

Using the ramrod push the pellet into the pellet loading port (forward of the bolt) remove and dis-

card the pellet. Do not reuse that pellet.

11.

Put the airgun “ON SAFE” (see firearm owner’s manual).

12.

Pressurize (see section 5a, 5b)

13.

If you are not able to unjam your airgun by following this procedure, take no further action. Cros-

man Corporation or an Authorized Service Station will unjam your airgun (no cost during the war-

ranty period).

Fig 10

A

B

Fig 11

Fig 12

Fig 13