COMP Cams 5491 Sprint Car Front Drive Kit for LS Engines User Manual

Page 6

COMP Cams

®

3406 Democrat Rd.

Memphis, TN 38118

Phone: 901.795.2400

Part #COMP4-158

Revised 8/10/12

Toll Free: 1.800.999.0853

www.compcams.com

Step 7: Proper backlash is 0.010-.015" of clearance between each gear. An easy way to attain this

setting is to run a stack of newspaper into the gears that is two sheets thick, then force the gears

together and tighten the two mounting plate bolts to 27 ft-lbs.

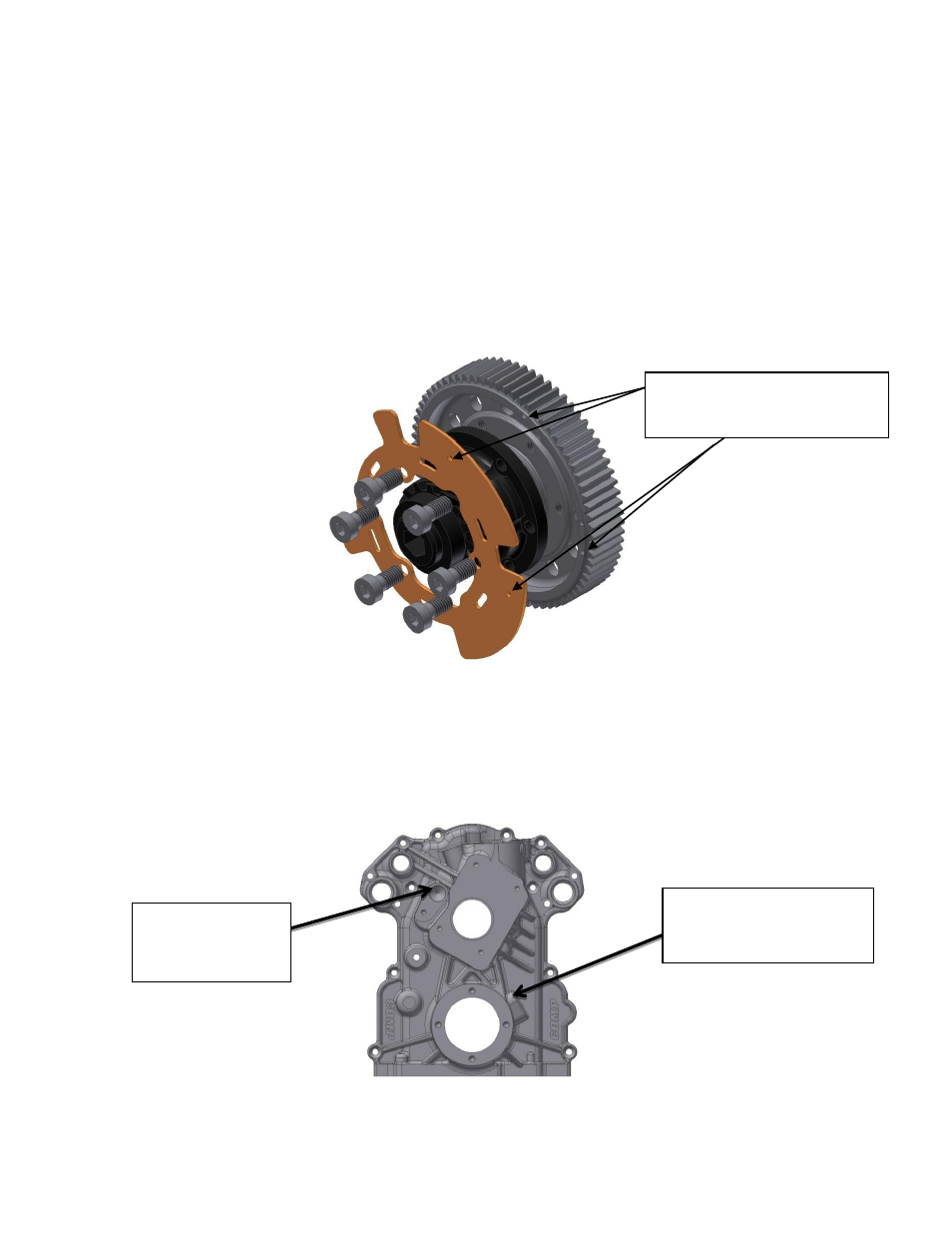

Step 8: Mount the oil pump/magneto adapter [15] and cam trigger wheel [10] (if using a cam sensor in

your set up.) Do this by locating the adapter onto the shoulder on the front of the cam gear. Install the

cam trigger wheel over top of the adapter so that you can see the two 1/8" holes in the cam gear

through the two holes along the perimeter of the trigger wheel. Then attach the adapter and trigger

wheel using the M6x16mm low profile socket head cap screws [31]. Torque to 10 ft-lbs.

Step 9: At this point, if you plan to use an integrated cam and/or crank sensor, drill out the appropriate

hole(s) in the cover. The cam sensor hole should be drilled to 20mm and the crank sensor hole to 5/8".

Figure 3: Sensor Holes

Cam Sensor Hole

Location. Drill to

20mm.

Crank Sensor Hole

Location. Drill to 5/8".

Hole in trigger wheel must

align with hole in cam gear.