Culligan Drinking Water System User Manual

Page 10

If you wish to service your system, the filters are available from your Culligan dealer. To locate your

nearest Culligan dealer, call (800) 285-5442, or visit our website at www.culligan.com. See the Parts

List at the end of this section for replacement numbers.

Cartridge Conditioning

The activated carbon, reverse osmosis, and polishing filter cartridges must be conditioned as follows

prior to installation into the Culligan Water Tower™ drinking water system. Your Culligan Man™ can

do these important procedures at the time of purchase.

Activated Pre-Carbon Filter Cartridge - 2 gallon flush to remove carbon dust

RO Membrane Cartridge - 24 hour flush to remove preservative solution

Activated Post-Carbon (Polishing) Filter Cartridge - 2 gallon flush to remove carbon dust

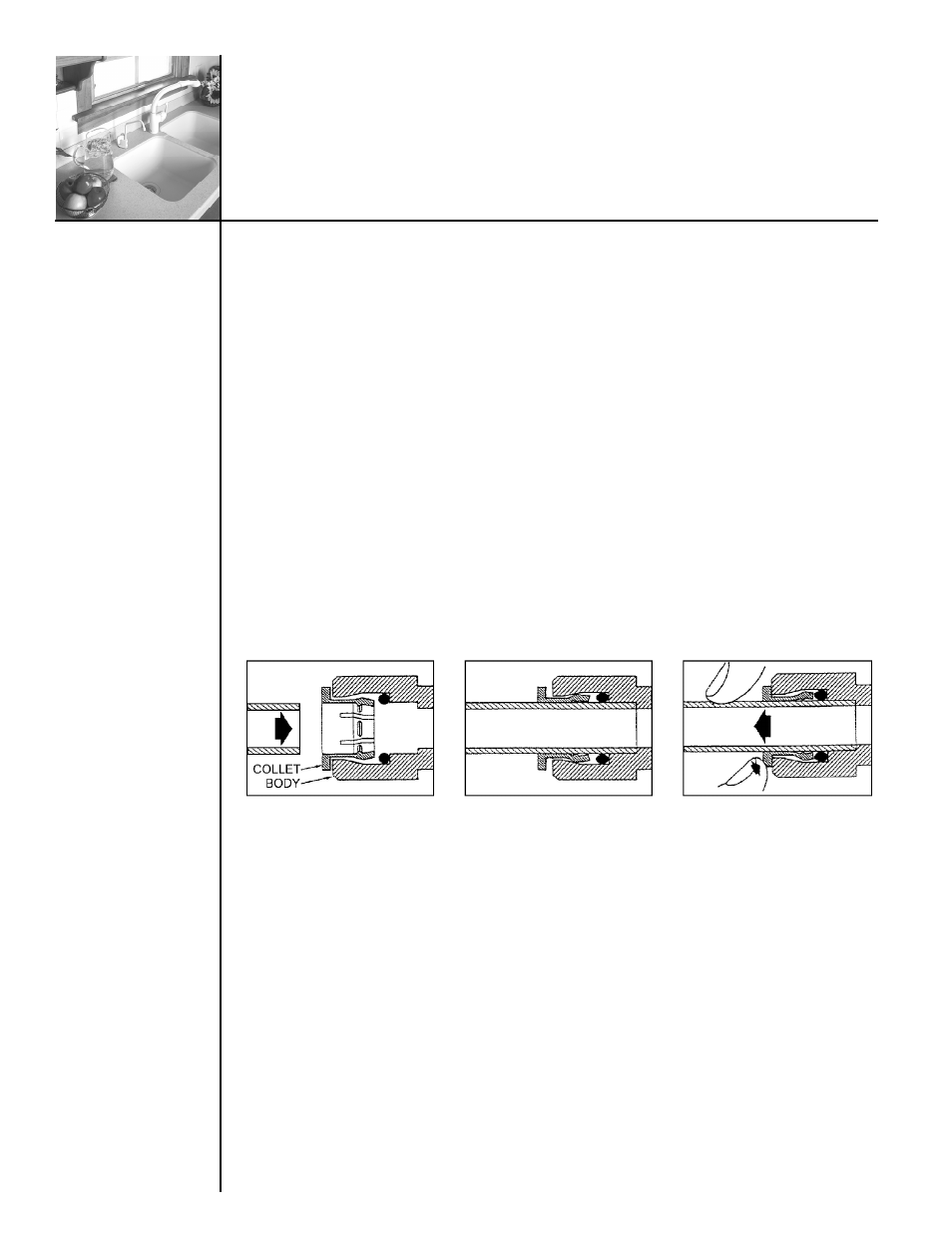

Tubing Connectors

The Culligan Water Tower drinking water system features easy-to-use push-in tubing connectors

(Figure 3). Fittings consist of two parts: a body and a colored collet. Collet color corresponds to tub-

ing color to be used at that connection (Figure 3A).

1. To install a tube, lubricate the tubing end with water (only) and push it through collet until it

seats firmly at bottom of fitting (Figure 3B). You should feel the tubing pass the O-rings. Cut

ends must be square. Be sure the tubing is smooth and free of abrasions, otherwise a leak may

result. Cut tubing only with a new razor blade.

2. To remove a tube, push and hold the collet against the fitting body and pull the tube from the

fitting. (Figure 3C).

Figure 3A

Figure 3A

Figure 3A

Cartridge Replacement, Cleaning and Sanitizing Procedure

1. Mix a mild cleaning solution of dish soap and clean potable water in plastic bowl.

2. Empty storage tank and relieve system pressure. Verify tank valve is open. Close feed water sup-

ply valve and open product water faucet.

Note: Additional point-of-use devices (i.e. icemakers) may use filters along their supply line.

Remove any filter or treatment device installed between module and delivery device before pre -

ceding.

Icemaker: Transfer ice cubes from bin/tray to clean freezer container for storage until procedure

is done.

3. Check product water storage tank air pre-charge using low-pressure gauge (PN 34002024). Air

valve is located on tank base. Pre-charge should be 55 kPa (8 psig) with tank empty and tank

valve open.

10