Step 9 — install flue hood and combustion air hood, Step 10 — install gas piping, Fig. 15 -- hood assembly – completed – Carrier SINGLE PACKAGE ROOFTOP 48HC User Manual

Page 16

16

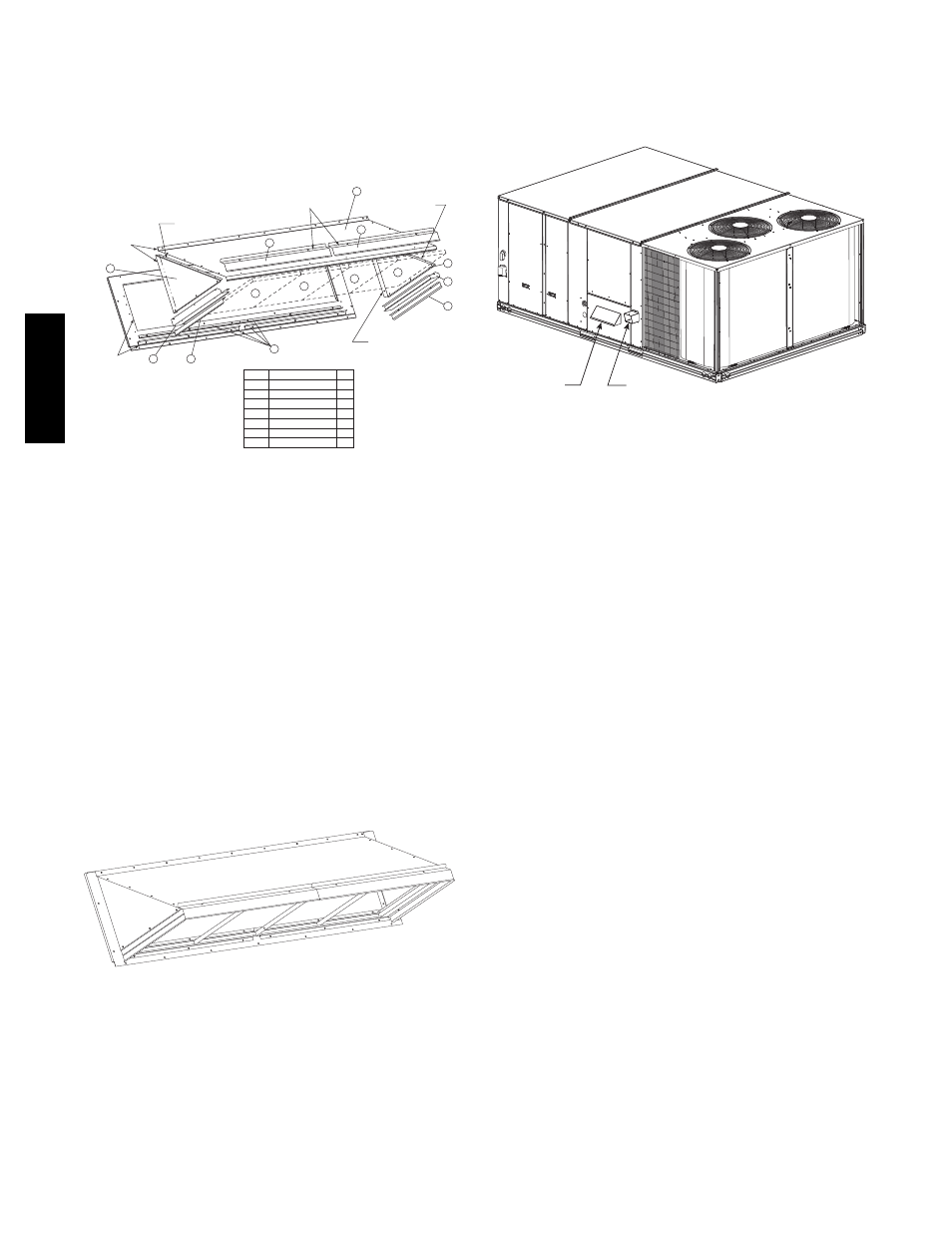

To assemble the outside air hood:

1. Remove hood top panel from shipping position on

unit end.

2. Install four angles to the upper end panel using the

screws provided.

3. Apply seal strip to mating flanges on the side plates

of the hood (see Fig. 14).

Apply Seal Strips

to the back of

these flanges

Apply Seal Strip

to the front of

this flange

Apply Seal Strip

to the front of

this flange

Apply Seal Strip

to the back of

this flange

Seal Strips

Apply Seal Strips

to the back of

these surfaces

7

7

2

2

1

3

4

4

4

4

5

6

5

6

Item #

Description

Qty

1

Angles

4

2

Side Plates

2

3

Hood

1

4

Outdoor

Air

Screens 4

5

Side Filter Supports

2

6

Side

Drip

Angles

2

7

Top

Diverters

2

C09079

Fig. 14 -- Hood Part Identification and Seal Strip

Application Areas

4. Secure side plates to panel using the screws provided.

5. Apply seal strip to mating flange of the hood (see

Fig. 14).

6. Secure top flange using screws provided in kit.

7. Install outdoor air screens by sliding them into the

channel formed by the four angles installed in step 2.

Make sure that the screens extend across the entire

length of the hood.

8. Install side filter supports using the screws provided.

9. Install side drip angles using the screws provided.

10. Run a continuous length of seal strip across the hood

covering the engagement holes in the lower hood.

11. Install top diverter using the screws provided.

12. On units with barometric relief, remove screws at bot-

tom of relief damper. Do not discard damper door.

C09090

Fig. 15 -- Hood Assembly – Completed

Step 9 — Install Flue Hood and Combustion Air

Hood

The flue hood is shipped screwed to the fan deck inside

the burner compartment. Remove the burner access panel

and then remove the flue hood from its shipping location.

Using the screws provided, install flue hood in the

location shown in Fig. 16.

The combustion air hood is attached to the back of the

burner access panel. Remove the two screws securing the

hood to the back of the burner access panel. Using the two

screws, re--attach the hood to the front of the burner

access panel as shown in Fig. 16.

Flue Hood

Combustion

Air Hood

C10744

Fig. 16 -- Flue Hood and Combustion Air Hood Details

Step 10 — Install Gas Piping

Installation of the gas piping must be in accordance with

local building codes and with applicable national codes.

In U.S.A., refer to NFPA 54/ANSI Z223.1 National Fuel

Gas Code (NFGC). In Canada, installation must be

accordance with the CAN/CSA B149.1 and CAN/CSA

B149.2 installation codes for gas burning appliances.

This unit is factory equipped for use with Natural Gas fuel

at elevations up to 2000 ft (610 m) above sea level. Unit

may be field converted for operation at elevations above

2000 ft (610 m) and/or for use with liquefied petroleum

fuel. See accessory kit installation instructions regarding

these accessories.

NOTE: Furnace gas input rate on rating plate is for

installation up to 2000 ft (610 m) above sea level. In

U.S.A. the input rating for altitudes above 2000 ft (610 m)

must be derated by 4% for each 1000 ft (305 m) above sea

level. In Canada the input rating must be derated by 10%

for altitudes of 2000 ft (610 m) to 4500 ft (1372 m) above

sea level.

For natural gas applications, gas pressure at unit gas

connection must not be less than 5 in. wg (1246 Pa) or

greater than 13 in. wg (3240 Pa) while the unit is

operating. For liquified petroleum applications, the gas

pressure must not be less than 11 in. wg (2740 Pa) or

greater than 13 in. wg (3240 Pa) at the unit connection.

Gas Supply Line —

The gas supply pipe enters the unit adjacent to the burner

access panel on the front side of the unit, through the

grommeted hole. The gas connection to the unit is made

to the

3

/

4

in. FPT gas inlet port on the unit gas valve.

Table 2 lists typical

3

/

4

inch NPT (National Pipe Thread)

field supplied pipe fittings required for Thru--Base gas

supply, starting from the unit gas valve (see Fig. 17).

48H

C