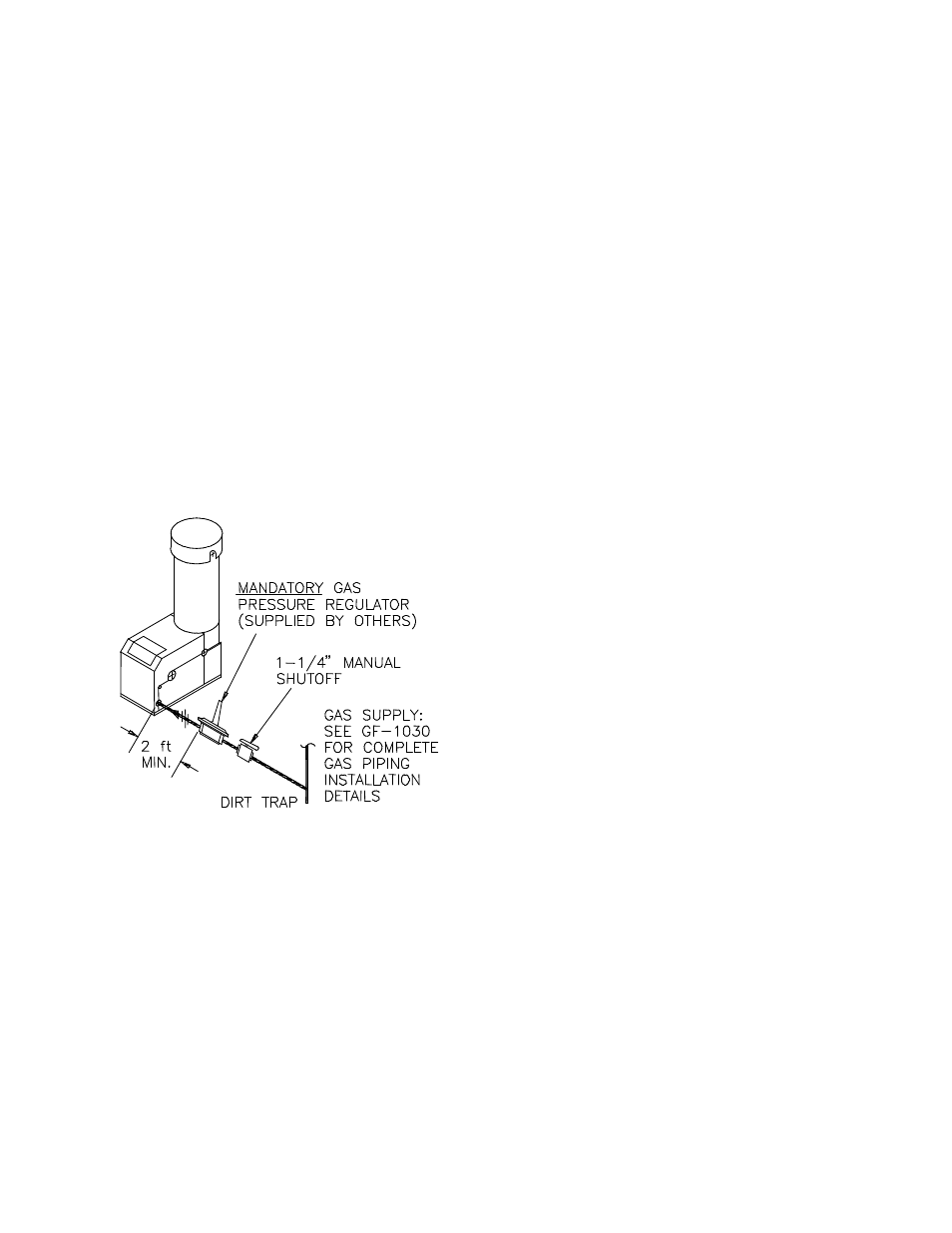

Figure 2.7, Installation – AERCO KC1000 Water Heater July 2011 User Manual

Page 13

INSTALLATION

2-5

The location of the 1-1/4" inlet gas connection

on the right side of the unit is shown in Figure

2.7.

All pipe should be de-burred and internally

cleared of any scale or iron chips before

installation. No flexible connectors or non-

approved gas fittings should be installed. Piping

should be supported from floor or walls only and

must not be secured to the unit.

A suitable piping compound approved for use

with gas should be used sparingly. Any excess

must be wiped off to prevent clogging of

components.

To avoid damage to the unit when pressure

testing gas piping, isolate the unit from the gas

supply piping. At no time should there be more

than 1 psig maximum to the unit. Bubble test all

external piping thoroughly for leaks using a soap

and water solution or suitable equivalent. The

gas piping must meet all applicable codes.

Figure 2.7

Gas Supply Regulator and Manual Shut -

Off Valve Location

2.4.1 GAS SUPPLY PRESSURE

REGULATOR

A mandatory external, in-line, supply gas

regulator (supplied by others) must be installed

upstream of each KC1000 and positioned as

shown in Figure 2.7. Union connections should

be placed in the proper locations to allow

maintenance of the regulator if required. The

regulator must be capable of providing the

required gas pressures for natural gas and

propane units as described in the paragraphs

which follow.

Natural Gas:

The maximum static inlet pressure to the unit

must be no more than 14” W.C. Minimum gas

pressure is 8.8” W.C. for FM gas trains and

9.2” W.C. for IRI gas trains when the unit is

firing at maximum input. Gas pressure should

not exceed 11.5” W.C. at any time when firing.

Proper sizing of the gas supply regulator in

delivering the correct gas flow and outlet

pressure is mandatory. The gas supply

pressure regulator must maintain the gas

pressure at a regulated 8.8” W.C. minimum

for FM gas trains and 9.2” W.C. for IRI gas

trains at maximum BTU input (970,000

BTU/HR) for natural gas installations. The

supply gas regulator must be of sufficient

capacity volume, (1000 cfh), for the unit and

should have no more than 1" droop from

minimum to full fire.

Propane:

The maximum static inlet pressure to the unit

must be no more than 14” W.C. Minimum gas

pressure is 7.7” W.C. for FM gas trains and

8.1” W.C. for IRI gas trains when the unit is

firing at maximum input. Gas pressure should

not exceed 11.5” W.C. at any time when firing.

Proper sizing of the gas supply regulator in

delivering the correct gas flow and outlet

pressure is mandatory. The gas supply

pressure regulator must maintain the gas

pressure at a regulated 7.7” W.C. minimum

for FM gas trains and 8.1” W.C. for IRI gas

trains at maximum BTU input (1,000,000

BTU/HR) for propane installations. The supply

gas regulator must be of sufficient capacity

volume, (400 cfh), for the unit and should have

no more than 1" droop from minimum to full

fire.

The supply gas regulator must be rated to

handle the maximum incoming supply gas

pressure. When the gas supply pressure will not

exceed 14” W.C. a non-lock up or flow through

style regulator may be used. When supply gas

pressure will exceed 14” W.C., a lock up style

regulator must be used. The gas supply

regulator must be propery vented to outdoors.

Consult the local gas utility for exact

requirements concerning venting of supply gas

regulators.

CAUTION!

A lockup style regulator must be used when gas

supply pressure exceeds 14” W.C.